Products

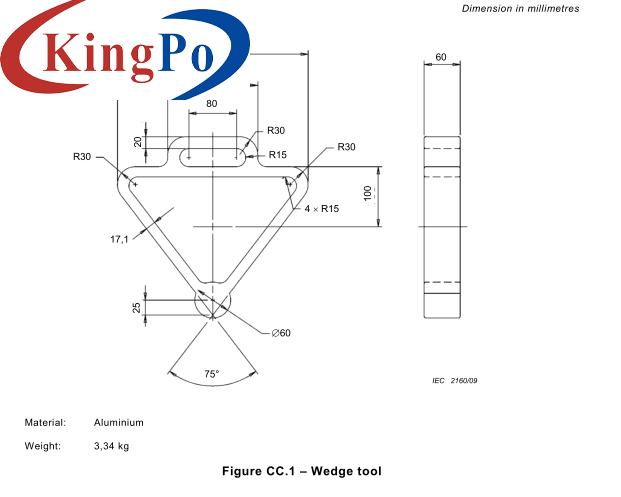

IEC 60601-2-52 Figure CC.1 Wedge Tool For Test Medical Bed In Non-moving Parts

Products Description

IEC 60601-2-52 Figure CC.1 Wedge Tool For Test Medical Bed In Non-Moving Parts

Standard & Clauses:

IEC60601-2-52:2015figure CC.1

Specimen Range, Application, Principle, Structure and Use Environment:

Specimen and Limitations: Medical Bed

Features:

To reduce the risk of neck entrapment, openings between elements in the MEDICAL BED systemabove the MATTRESS SUPPORT PLATFORM should be small enough to prevent passage of asmall neck. Additionally to reduce neck entrapment with regards to wedging of the neck,angles for V-shaped entry into the openings should be greater than 75°. The 75° anglereflects an understanding that at some point, a narrow angle creates a V-shaped space orgeometry that could be conducive to entrapment, The 75° angle was chosen by reviewing thetools to assess entrapment risk for swimming pool equipment (see EN 13451-1) and makingchanges suitable to application on MEDIcAL BEDs by increasing the wedging minimum angle o60° to 75°. The 75° angle reduces the RiSK of PATlENT entrapment through hooking of the neckand head in the V-shaped opening (See Figure AA.13 and Figure AA.15). The wider angleallows the PATiENT to pull his head free from a vertical opening with less effort. This isessential when considering a weak or confused PATIENT.

Test purpose: used to evaluate the risk of V-shaped openings getting stuck in areas B and C between the edge of the medical bed, the headboard/footboard and the mattress support platform, and to verify whether the gaps meet the standard requirements.

Test principle: Use a wedge-shaped tool to measure at various positions required by the standard, and judge according to the standard.

Equipment structure and features: Made of aluminum

Weight: 3.34kg

To measure V-shaped openings in relation to areas B and C a test method and wedge tool(see Figure CC,1) has been developed, The tool is made from aluminium and weighs 3,34 kgrepresenting the mass of a small aduits head and neck (the 3,34 kg was taken from Air ForceResearch laboratory Design and Development of Anthropometrically Correct Head Forms forJoint Strike Fiahter Eiection Seat Testing-February 2005), the wedge angle is 75° and has a60 mm diameter cylindrical end representing the small adult neck.