Events

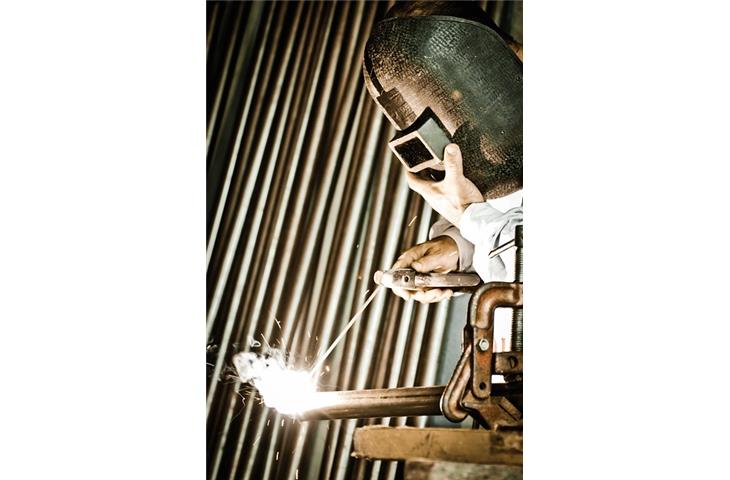

The Essential Guide to Thermocouple Welding Machines When Needed

News 2025-01-08 83

For anyone involved in exact welding uses, temperature couple welders are a vital piece of equipment.These specific devices attain excellent joins with least warping by using the concepts of thermocouples that create voltage in response to a temperature gradient.Several important considerations must be to be taken into account when you are selecting the right thermocouple welding machine for your needs, to ensure best performance and efficiency.

1. Compatibility of welding material2. power for welding and rapidityThe power for welding and rapidity of the thermocouple welding machine are very important in deciding the standard and efficiency of the weld.A higher power for welding enables deeper penetration and faster welding rapiditys, thus making the process more productive.

Yet, too much power can cause excess heat and inferior welding.An essential selection standard is a machine's power level that matches specific use needs.By matching the power for welding and rapidity of the machine with your specific use needs, the highest quality outcomes can be attaind.

3. Warmth management and AccuracyExact temperature management is necessary for Resistance fusion via temperature couple machines to Maintain stable and superior welds.They typically are equipped with Integrated thermodynamic detectors and controllers that offer and Modifications.For materials with Low-temperature melting materials or those subject to Heat-induced, accurate Warmth management is Vital.

4. Mobility and UsabilityWorking in remote or Portable workspaces makes the Mobility and Usability of a Resistance fusion via temperature couple machine Important.Compact and delicate constructions facilitate Carrying and Installation of the equipment, while user-friendly interfaces and intuitive controls Facilitate the welding process.

In conclusion, when selecting the right Resistance fusion via temperature couple machine for your needs, it is Important to consider several critical factors.Through emphasis on (welding Material congruity), Welding amplitude and speed, Warmth management and Accuracy, and Mobility and Usability, the ideal tool for the Use can be guaranteed.

Related articles

- What to Look for in a Softness Tester Manufacturer

- What You Need to Know About Testing Equipment Rental

- When Portable Ultrasonic Testing Equipment Meets Real-World Needs

- Ensuring Accuracy: The Importance of Bone Density Quality Control Tests

- The Essential Role of Test Fixture 17 Probe GR-F1117 in Quality Assurance

- What Sets IPX6 and IPX7 Apart?

- The KP3020: A Comprehensive Overview

- Why Kunststof Planten Xing is a Game Changer