Events

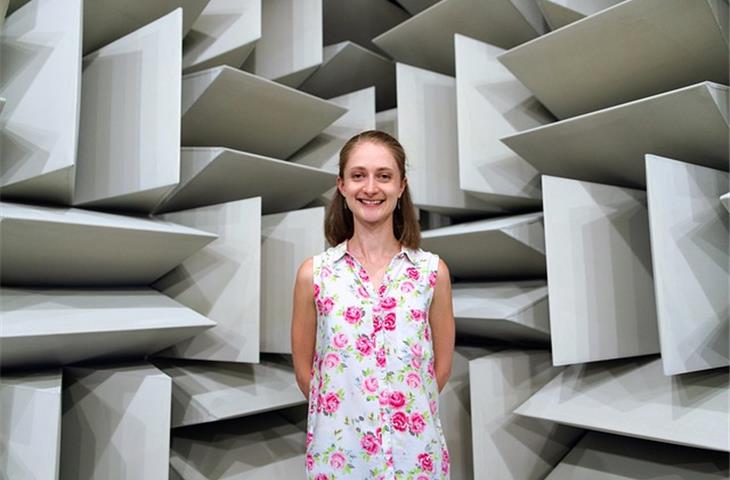

Inside the High and Low Temperature Alternating Test Chamber

News 2025-01-08 116

Various industries use the sophisticated piece of equipment known as the extreme temperature tester to evaluate the robustness and performance of composites at harsh thermal environments.The extreme temperature tester simulates rapid temperature changes, which are essential in evaluating how materials respond to such weathering pressures.

We will delve into the complexities of the extreme temperature tester in this article, including its uses, functionality needs, and the importance of ensuring accurate thermal regulation.The capacity for keeping precise climate regulation is one of the primary requirements of a extreme temperature tester.

Accurately setting and maintaining temperatures across a wide range, typically from -70°C to 200°C or more, must be possible for the chamber.The accuracy of the climate regulation is crucial, because slight temperature deviations can significantly affect .The even thermal distribution throughout the chamber is another critical feature of a extreme temperature tester.

To guarantee trustworthy and precise outcomes, test samples should experience consistent heat fluctuations.Achieving consistent heat spread often requires a meticulously arranged apparatus of heating and refrigeration components.quickly transitioning between extreme heat ranges is a principal characteristic of these testing apparatuss.

quick heat fluctuations can simulate actual life scenarios, providing useful understandings into material response to pressure.The speed of the apparatus's heat alternation between extreme heat ranges is often measured in °C per minute interval interval (°C/min).Paramount in the functioning of a upper and lowerererer heat switching testing apparatus is security.

security protocols must be equipped in the apparatus to avert harm to the test samples or to the testing environment.Vital for a upper and lowerererer heat switching testing apparatus is ensuring accuspeed heat regulation.The precision of the heat regulation mechanism has a direct impact on the dependability and precision of the outcomes of the test.

A major issue in the design of a extreme temperatures alternating test chamber is achieving even heat distribution.The convection process involves the transfer of heat through the fluid movement like air or water.For quick temperature cycling, the chamber must be equipped with efficient heating and cooling mechanisms.

The chamber design inside also plays a significant role in achieving quick temperature cycling.The crucial feature of a extreme temperatures alternating test chamber is the fast temperature change capability through extreme temperaturess.quick temperature shifts can simulate real-life conditions, thereby providing valuable insights into material response to stress.

For quick temperature cycling to be achieved, the chamber must be equipped with efficient heating and cooling mechanisms.In addition to safety mechanisms, the chamber should also be designed to minimize energy usage, as well as reduce the environmental effect of its operation.In conclusion, testing the sturdiness and functionality of materials under severe temperature extremes, the extreme temperatures alternating test chamber is a crucial piece of machinery.

Related articles

- Innovating the Battery Pack Testing Machine Factory

- High Temperature Oil Bath Market Dynamics

- Essentials of Protective Equipment Testing Instruments

- Unveiling the BCM7425ZZKFEB1G: A Journey into Demand

- The Why and What of Bench Test Equipment

- When Tensile Strength Testers with Chambers Come into Play

- Medical Test Equipment Hinges: A Comprehensive Guide

- The Why Behind IPX4 Water Rating