Products

IEC 60335-2-2 Clause 21.101 Current-Carrying Hoses Comprehensive Test Equipment

Products Description

IEC 60335-2-2 Clause 21.101 Current-Carrying Hoses Comprehensive Test Equipment

Product Information

Standard: IEC60335-2-2:2009 ”Household and similar electrical appliances-Safety-Part2-2:Particular requirements for vacuum cleaners and water-suction cleaning appliances, IDT” clause 21.101, 21.102, 21.103, 21.104.

Specimen and limitations: Vacuum cleaner hoses, water suction cleaning appliance hoses, washing machine hoses

Test purpose: Used to assess the mechanical strength of vacuum cleaner hoses in terms of resistance to extrusion, abrasion, bending and torsion.

Test Principle

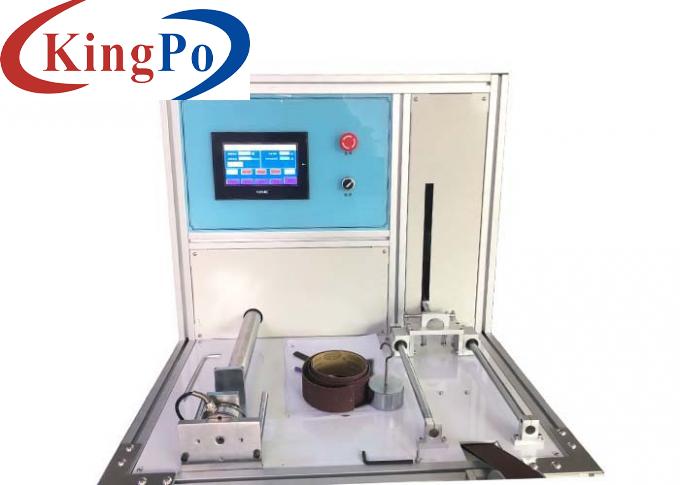

This equipment is a four-in-one comprehensive testing equipment. It adopts PLC control, touch screen operation, and controls the motor to drive the mechanical arm to realize various tests.

1. Extrusion resistance test: A system-controlled motor is used to drive the sensor to apply a force value. A 100*50mm pressure plate (corner rounding R1mm) is pressed to the sample 350mm away from the end of the hose at a speed of 50±5mm/min, reaching 1500N After releasing, it will return to the origin automatically.

2. Abrasion resistance test: The crank mechanism rotates at a rate of 30r/min, and the current-carrying hose sample is made to reciprocate 300mm back and forth 100 times through the connecting rod. At the same time, the hose is supported by a rotating smooth roller, and an emery cloth belt is attached to the outer edge of the roller, moving at a speed of 0.1m/min. The abrasive of the emery cloth is emery, and the particle size is Pl00 according to ISO 6344-2. A weight of mass 1kg is hung from the other end of the hose as a guide to prevent the hose from rotating. At the lowest position, the maximum distance between the weight and the center of the roller is 600mm. After the test is completed, the basic insulation shall not leak and the electrical strength test of 16.3 shall be carried out between the connected conductors and the salt solution.

3. Bending resistance test: The system controls the motor to drive the eccentric mechanism to lift the robotic arm (to 40±1°). The number of tests and the test speed can be preset, and the machine will automatically stop when the number of times is reached.

During the test, the end of the current-carrying hose intended to be connected to the power cleaning head is fixed on the pivot arm of the device. The distance between the pivot arm axis and the point where the hose extends into the rigid component is 300 ± 50 mm. A weight with a mass of 5kg is hung on the other end of the hose (the weight can slide along the weight slide), the pivot arm rises from the horizontal to 40°±1°, and the cycle is repeated 2500 times. Then turn the end of the hose to 900 and repeat the above test 2500 times. After the test is completed, conduct an electrical strength test on the sample.

4. Twist resistance test: The system controls the motor to drive the rotating shaft to rotate and twist the sample. During the test, the end of the current-carrying hose is fixed on the rotating fixture of the equipment (self-suspended), and the other end is locked to the horizontal fixture. Each cycle rotates 5 times forward and 5 times reversely at a rate of 10 r/min, and conducts 2000 cycle tests. After the test is completed, conduct an electrical strength test on the sample

Technical Parameters

1. Current-carrying hose extrusion resistance test

2. Current-carrying hose abrasion resistance test

3. Current-carrying hose bending resistance test

4. Current-carrying hose torsion resistance test

1. Force range: 10-2000N, default 1500N, resolution 0.1N

2. Test speed can be set from 10-100mm/min, default is 50mm/min

3. Pressing plate LWH=100×50×20mm, long edge rounded R1, made of stainless steel

4. Force action: fully automatic

1. Test speed: 30r/min, can be preset

2. Roller diameter: 120mm

3. Horizontal moving distance of hose: 300mm, eccentric adjustment

4. Abrasive belt moving speed: 0.1m/min

5. Emery belt: ISO/DIS6344 requires a size of P100 abrasive belt

6. Heavy object: 1kg

7. At the lowest position, the distance between the weight and the center of the roller: 600mm

8. Number of tests: 0-999999 times, can be preset, default is 100 times

1. Test speed: 10r/min, can be preset, accuracy ±1r/min

2. Bending angle: 40°±1°

3. Load weight: one each of 2.5 and 5kg

4. Swing arm length: 300mm±50mm

5. Number of tests: 0-999999 times, can be preset, default is 10000 times

6. Metal slope: When the weight is moved up and down, the maximum deflection angle of the hose is 3°, and the vertical deflection angle from the slope is 3°±1°.

1. Test speed: 10r/min, can be preset

2. Rotation direction: forward and reverse, automatically switch according to the set number of times

3. Number of forward/reverse rotations: 5 times, can be preset

4. Operation cycle: 0-999999 times, can be preset, default is 2000 times, one cycle is 5 forward rotations and 5 reverse rotations at a rate of 10r/min

Test station

Combined type, four stations, each station can be tested independently

Electrical control method

PLC intelligent electrical control, touch screen operation

Drive mode

Motor drive

Test items

Extrusion resistance test parameters

Abrasion resistance test parameters

Bending resistance test parameters

Torsion resistance test parameters

Equipment structure

The device adopts a floor-standing structure with casters.

Power supply

AC220V±10%/50-60Hz,3kW

Equipment size

WDH=1500X1200X1650mm

Equipment weight

About 230kg