Products

ISO23953-2 Vertical Refrigerator Door Opening And Closing Testing Machine Durability Test

Products Description

ISO23953-2 Vertical Refrigerator Door Opening And Closing Testing Machine Durability Test

System overview:

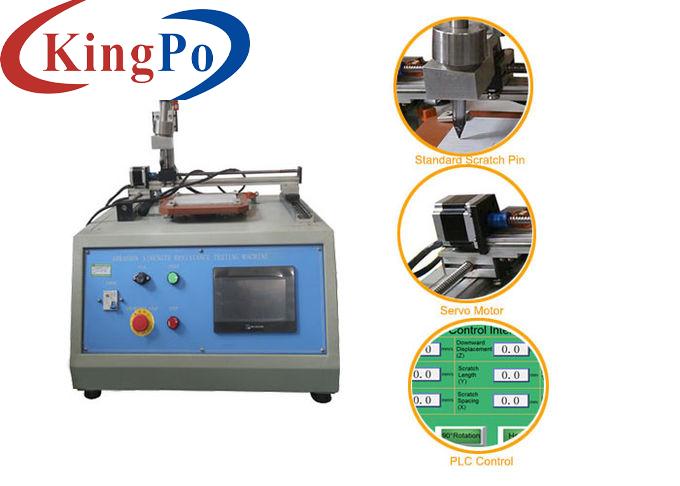

The vertical refrigerator door opening and closing test machine is designed and manufactured according to Chapter 5.3.3.2 of ISO 23953-2:2015(E) and customer-specific requirements. It is used for the vertical door opening and closing durability test of vertical refrigerators, also used to match the door opening and closing actions during energy efficiency performance of refrigerators. It is a dedicated fully automated testing equipment for testing the opening and closing of refrigerator doors, which is suitable for testing departments such as testing and certification agencies, factory laboratories, etc.

This equipment adopts PLC intelligent control with mature technology, equipped with position-adjustable action actuator, and vacuum suction cup structure to absorb the surface of the refrigerator. At the same time, it is equipped with a color LCD touch screen as standard, which can preset the door opening angle, door opening and closing speed, door opening pause time, and interval time. In this way, it can truly simulate the opening and closing of the refrigerator door by hand, and achieve an intelligent control method, one machine with multiple functions.

Equipment principle:

Equipment principle: PLC control, intelligent touch screen operation, servo motor drives the manipulator, drives the door which is sucked by the vacuum suction cup to be opened and closed reciprocatingly.

Process flow:

The structure of the testing machine as shown in the figure below, the overall frame structure is adopted, and the sample is placed on the bottom plate of the equipment, so that the relative movement is the internal stress, and the shaking of the equipment is reduced. A column structure is installed on the bottom plate, and the column contains a set of doors opening and closing mechanism as shown in Figure 1. At the same time, the refrigerator positioning fixture is installed on the bottom plate, which can clamp and fix the left, right and rear sides of the refrigerator. Applicable samples are as shown in Figure.

Technical Parameters:

The same types of samples shown in Figure 2

WDH=(65~70cm)×(70~80cm) ×(160~200cm)

Refrigerator door opening and closing durability test

(for door only open to the right)

Refrigerator

Step

Content

Execution time

Step 1

Open the lid and close

3min

Step 2

Open the lid to >80%

1s

Step 3

Keep opened

13s

Step 4

Close the lid

1s

Step 5

Keep closed I

5min45s

Step 6

Repeat steps 2-5

11h54min

Step 7

Keep closed II

12h

Freezer

Step 1

Open the lid and close

3min

Step 2

Open the lid to >80%

1s

Step 3

Keep opened

4s

Step 4

Close the lid

1s

Step 5

Keep closed I

9min54s

Step 6

Repeat steps 2-5

11h50min

Step 7

Repeat closed II

12h

No.

Project

Content

1

Input power

AC220V 50HZ, 5kW

2

Electrical control

Mitsubishi PLC intelligent control

3

Operation interface

Weinview 7-inch color man-machine interface touch screen operation

4

Drive mode

Opening and closing test: servo motor + precision reducer

5

Range of samples

6

Test items

7

Test station

1 station, can test a right-open door type vertical refrigerator

7

Axis of rotation

The door opening and closing position of the can be matched by adjusting the height position of the manipulator and the position of suction cup on the rotating shaft

8

Robotic arm

1 set of door opening and closing manipulator, which can adjust the opening and closing positions (that is, adjustable in length and height directions), suitable for refrigerator doors of different heights and widths

9

Adsorption structure

Vacuum suction cup, continuous and stable adsorption, 1 set

10

Door opening angle

0-70°±0.1°, can be set on touch screen

11

Door first opening time

3min

12

Door opening pause time

0-9999S, can be set on touch screen

13

Door closing pause time I

0-99h59m59s, can be set on touch screen

14

Door closing pause time II

0-99h59m59s, can be set on touch screen

15

Door open/close speed

10-90°/s, can be set on touch screen

16

Refrigerator auxiliary positioning mechanism

3 sets, which can fix the sides and back of the refrigerator

17

The frame

Match the largest sample range, sample is installed on the bottom plate of the equipment

18

Power failure memory

The system has a power failure memory function, which can continue to accumulate parameter actions and times before power failure

19

Protect

Emergency stop, leakage, short circuit, overload and other safety protection

20

The overall size and weight of the testing machine

Frame: W1300*D1300*H2300mm, approx. 350kg