Events

When Precision Meets Force: The Essential Guide to Torque Testing Machines

News 2025-01-08 83

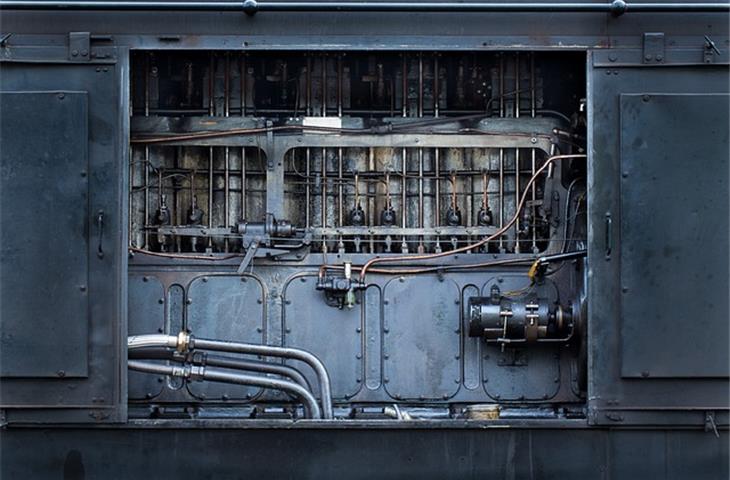

The rotational-force tester stands as a cornerstone of exactness and dependability in the realm of mechanical engineering and product quality assurance.This specialized equipment, designed to measure the necessary force to rotate an object, is crucial for ensuring the proper functioning of various parts and mechanisms.

The demand for accurate rotational-force testers continues to evolve, reaching a never-before-seen level of demand.This article explores the significance, applications, and fundamental prerequisites that designers and producers must consider when selecting the right rotational-force tester, diving into the world of such machines.

A primary demand of a rotational-force tester is its ability to provide exact measurements.Engines rely on these machines to ensure that components are within the specified torque limits, impacting the functioning and security of the end product directly.high-precision sensors and adjustment routines must be equipped in rotational-force testers to meet this demand, guaranteeing accurate and consistent results.

The flexibility of a torque tester is essential, as it must suit to a broad range of test applications.In automotive and aerospace sector, to consumer products and power equipment, these machines must be able to testing different sorts of fastening devices, bolts, and nuts.Manufacturers must create equipment that can support various sizes, ingredients, and test configurations to satisfy the requirement, ensuring that they can be used in multiple industries.

For the effective functioning of a torque tester, a intutive interface and programming are essential.Engineers and technologists should be able to rapidly configure tests, observe progress, and examine outcomes without the need for in-depth training.Manufacturers must prioritize the creation of intutive programming and interfaces to satisfy the requirement, streamlineing the test procedure and reducing the possibility of mistake.

The building and robustness of torque evaluation instruments are of paramount importance, considering the stringent conditions under which they are often used.torque evaluation instruments must be able to withstand severe conditions, such as severe temperatures, shakiness, and exposure to chemicals.to fulfill this need, makers should use premium materials, designing their products with a emphasis on sustained reliability and maintenance.

In the pursuit of accuracy, the precision of the torque tester is paramount.To achieve this, these machines are equipped with high-precision torque transducers capable of detecting even the smallest changes in force.calibration routines are also crucial, ensuring that the machine's readings are precise and reliable through duration.

routine upkeep and calibration checks are essential to preserve the accuracy of the readings provided by the torque testing machine.The flexibility of the torque gauge in diverse sectors is a testament to its versatility.From testing the torque of vehicle bolts to assessing the functionality of electrical tool parts, these machines are designed to handle a wide range of applications.

To address this need, manufacturers concentrate on creating machines that can cater to various sizes and different kinds of fasteners, as well as various testing setups, including tensile, compression, and angle testing.The effectiveness of a torque testing machine depends on a crucial element: the user experience.

Manufacturers emphasize the creation of user-friendly software and user interfaces to guarantee that engineers and technicians can operate these machines effectively.These tools are crafted to enable users to simply set up tests, track progress, and analyze outcomes, minimizing the chance of errors and enhancing productivity.

The long-lasting performance and dependability of a torque testing machine are vital because of its robustness.To address this need, manufacturers employ premium materials and design their equipment with an emphasis on resistance to damage.This involves the use of robust components, such as precision ball bearings and reinforced frames, ensuring that the machine can endure the stresses of continual use.

To sum up, the realm of mechanical design and quality assurance reaps the benefits of the crucial tool which is the.Its offering of exact, versatile, and easy-to-use testing methods turns it into an essential asset for engineering professionals and producers in a range of industries.Individuals can make intelligent choices when choosing the appropriate torque testing machine for their particular requirements through understanding its basic needs, thereby guaranteeing so that their products attain the top standards of excellence in quality and functionality.

Related articles

- In-Depth Guide to Biocompatibility Testing Equipment

- A Comprehensive Guide to Surgical Tools Names and Their Uses

- When Packaging Testing Meets Medical Devices

- When IPX Testing: Ensuring Robust Waterproof Electronics

- Current of 150ma: Essential Demands and Solutions

- Ensuring Safety: The Role of GB9706 in Medical Electrical Testing Equipment

- Essential Aspects of Household Appliance Testing Equipment

- Essential Insights on Package Leak Testing Equipment Where Needed