Events

How Thrust Testing Powers Innovation

News 2025-01-12 92

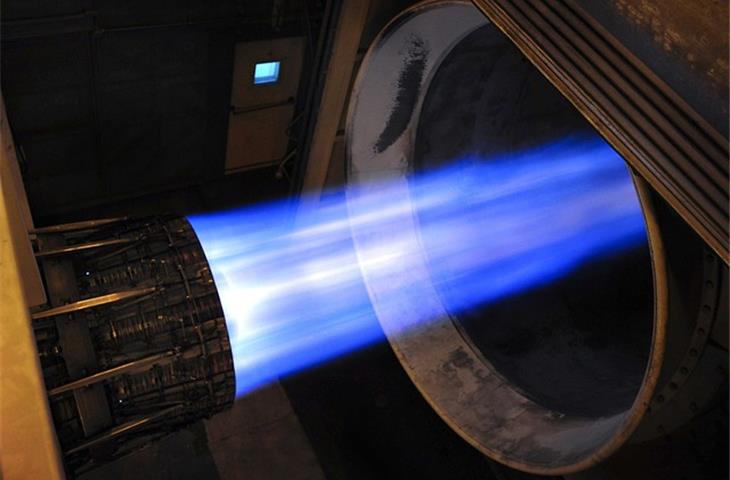

In the progress of various mechanical and aerodynamic systems, including those for aircraft engines and rocket propulsion systems, thrust testing is a crucial procedure.A assembly is submitted to regimented forces within this procedure to assess its execution and stability.Understanding how a system behaves under different thrust intensities allows designers to design more effective and reliable solutions.

The significance of thrust testing is delved into by this article, outlining four key demands associated with the procedure and exploring how it drives innovation across a diverse sectors.designers need precise data for accurate force estimation in thrust testing, to determine the execution characteristics of a system under various conditions.

The importance of selecting the right equipment and techniques for force estimation in thrust testing is discussed in this section.uniform testing procedures are essential to ensure the uniformity and stability of results.This part of the article examines the need for well-clear test protocols, along with how they contribute to the complete effectiveness of thrust testing.

thrust measurement enables immediate data analysis, allowing technical professionals to make quick modifications and optimize the system operation.This section highlights the benefits of immediate data analysis, showing its function in progressing the development of high-precision parts.thrust measurement involving operating conditions replication is vital to accurately predicting the system operation in actual environments.

The importance of environmental and load condition replication in thrust measurement, and its impact on the reliability of test outcomes, is discussed in this article.technical professionals rely on precise force readings in the realm of thrust measurement, utilizing accurate data to analyze the functionality and resilience of a system under different force intensities.

Selecting the suitable devices and techniques for force measurement is necessary to achieve this accuracy.Commonly used in thrust measurement are power measurement devices like strain gauges and load cells, which must be able to measure forces within the intended range with exacting accuracy.Ensuring accurate results requires standardization and ongoing upkeep of these sensors.

Another critical factor for force gauging is the choice of test arrangement.designers need to establish configurations that reduce errors and increase precision of force gaugings.In designing the setup, consideration should be given to factors like the material characteristics of the tested component, the anticipated force range, and the need for kinetic testing.

They describe steps, necessary tools, and circumstances of execution a thrust trial.Comparison across different tests and between various testing centers is enabled through compliance to uniform procedures.Including specifications for both equipment and settings, uniform procedures often specify the order of actions to be taken during testing.

uniform protocols ensure that the data acquired from thrust trialing are stable and dependable.In the progress of mechanical and aerospa, instantaneous data processing, providing prompt understanding into a machine functionality, is transformative.Such systems, capable of acquiring and analyzing information swiftly, allow engineers to observe system dynamics in real time.

Gathered data can be examined to spot any irregularities or points of concern.Environmental factors and operational loads simulation process, its importance cannot be exaggerated.submitting a system to the conditions it will experience during use, engineers can guarantee the system's dependable and secure operation.Operational load simulation process includes the application of stresses that simulate the stresses a system will encounter during use.

Environmental and Operational load simulation process cannot be exaggerated in its importance. It enables engineers to identify potential system deficiencies and address them before the system goes into operation.This guarantees the system's dependable and secure operation over its entire lifespan.Thrust testing procedure is critical in the creation of mechanical and aerodynamic systems.

With an emphasis on precise force measurement, standardized testing procedures, live data analysis, and simulation process of Environmental factors and operational loads, engineers can create more effective and dependable products.As the need for high-performance systems persists in growing, the importance of thrust testing procedure in encouraging innovation will only intensify.

Related articles

- Innovative Solutions for Hot Compress Fever Measurement System

- IEC 61000-4-8: Unveiling the Electromagnetic Compatibility Standards

- Key Requirements for a Top-Notch Resistance Test Instrument Manufacturer

- Discounts Galore at China's Top Toilet Screw Caps Mould Factory

- Nuts and Bolts Strength Reviews

- Optimizing Precision: The Role of Go/No-Go Gauges for Diameter Measurement

- Dental Injection Equipment: Essential Needs and Considerations

- Innovative Solutions for Lithium Battery System Testing Equipment