Products

Appendix F Of TÜV Rheinland 2Pfg 2577/08.16 Robot Cable Bending Testing Machine

Products Description

Appendix F of TÜV Rheinland 2Pfg 2577/08.16 Robot Cable Bending Testing Machine

Product Information:

Standard: Appendix F of TÜV Rheinland 2Pfg2577/08.16 "Requirements for cables used in robot system"

Specimen and limitations: Industrial robot cables.

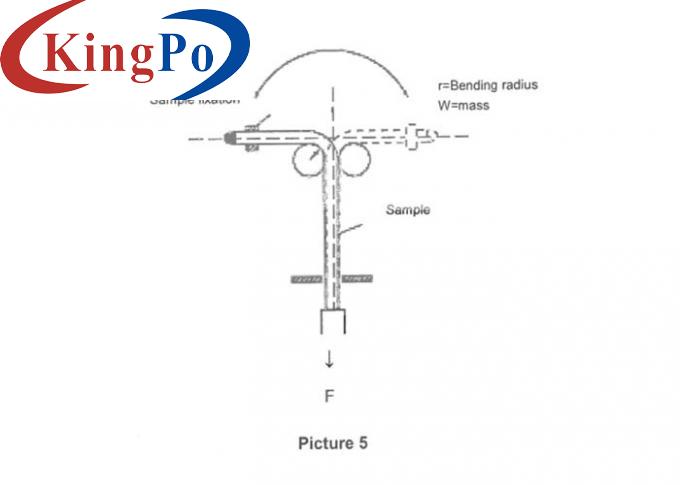

Test purpose: Used to test the bending resistance of the power cord of industrial robot cables when entering the joint.

Test principle: Using PLC control and servo motor drive, the bending test of industrial robot cables is carried out, and a certain load force is applied to the free end of the sample. The test speed, angle and number of tests can be preset through the touch screen.

Equipment structure and features: Chamber-type operating structure, strong versatility. The equipment is driven by a servo motor, with a centrally installed clamp, and the up and down eccentricity is adjustable. When clamping the sample, the swing axis and the point where the soft wire enters the instrument can be coincident as much as possible, thereby achieving the minimum lateral displacement of the cord and load.

Technical Parameters:

Mechanically clamped to a special fixture, the clamping point position is adjustable

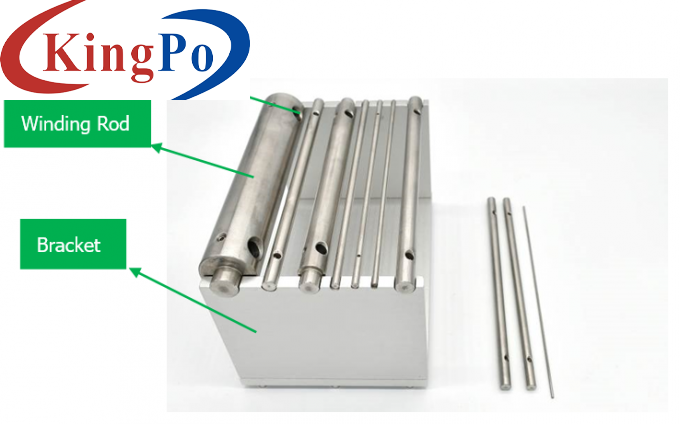

Roller diameter: Φ10mm; 20mm; 30mm; 50mm; 75mm; 100mm. 2 each

Rotation method: built-in bearing, can rotate with the sample (driven)

Material: Nylon

Control system

PLC control, 7-inch color touch screen operation

Drive mode

Servo motor + precision reducer transmission mechanism

Station

Single station, customizable 6 stations

Test items

Bending test

Main technical parameters of bending test

Sample

Industrial robot cable Φ1.0 ~ Ф40mm

Sample clamping method

Bending angle

0-360° adjustable (can be preset to ±30°, ±45°, ±60°, ±90°)

Bending direction selection

Bending rate

0-60 times/min, touch screen preset

Bending times

0~999999 can be preset, the default is 100 times

Load weight

0.5N/mm², standard configuration: one each of 0.5, 0.75, 1.25, 2, 3, and 5N

Roller

Distance between load-bearing weight and bending point

50-250 mm (adjustable)

Sample rotation point to hanging weight height

150-500 mm (adjustable)

Equipment size

WDH=1500X800X1820mm

Equipment weight

About 180kg