Events

Buy Premium Adhesion Test Panels

News 2025-04-17 15

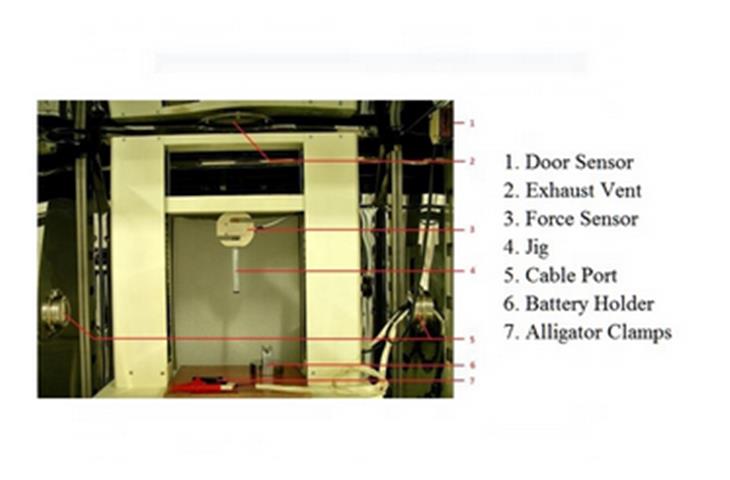

Adhesion test panels are crucially important for verifying quality in numerous industries. These devices are designed to assess how robust the is between two distinct materials, so that the material they produce is sturdy and dependable. We will delve into why These devices are so important, their application, and how they contribute to the success of many industries.

Material Compatibility

One significant aspect about These devices consists of their ability to examine to verify if various materials can adhere to one another. These devices can also assess to evaluate if adhesive adheres effectively to a surface or whether paint adheres to a surface. This is an effective method to determine the strength of the bond.

Take automotive industry, for example. They use those panels to make sure the paint really sticks to the car so it doesn't peel off and doesn't make the car appear poor. A survey said that most manufacturers, like 80%, employ these to ensure their quality is satisfactory.

Quality Control and Assurance

Those panels are super important for making sure things are quality inspected. They can spot issues in advance, keeping costs down and stops the need for repairing in the future.

A friend from the technological aspect said, 'We've been using these for five years and our stuff just got a whole lot better. Failure rates decreased by 30%' cause our connections significantly improved. This example highlights the importance of adhesion test panels in maintaining excellent quality.

Environmental Testing

They can also simulate what objects go through in actual life, like temperature fluctuations and sunlight exposure, to see if the connection sustains over time.

This is super important in industries like construction and aeroplane manufacturing, where materials has to cope with a lot more wear and tear. A major study said that about 70% of building materials doesn't hold up because it doesn't bond properly. By employing these panels can help make sure that the materials can cope with whatever setting they're in.

Cost-Effectiveness

Manufacturers save a significant amount of money by spotting and fixing connectioning issues early on, rather than having to fix or throw away defective items later.

Another survey showed that these panels can cut manufacturing expenses by 25% for companies utilizing them. This highlights the value of adhesion test panels in enhancing the production process.

Related articles

- IEC Test Equipment List PDF: A Comprehensive Guide

- What to Look for When Buying a Tensile Strength of Foam Tester

- Medical Power Safety Test: Ensuring Safe Practices in Healthcare

- The Essential ISO 80601-2-70: A Comprehensive Overview

- Decoding 'ul vw-1': Where It Stands and Its Relevance

- Why LED Light Testing Equipment is Essential in Modern Lighting

- Altitude Training: What Altitude Chambers Reveal

- Why Dishwasher Test Equipment is Essential for Quality Assurance