Products

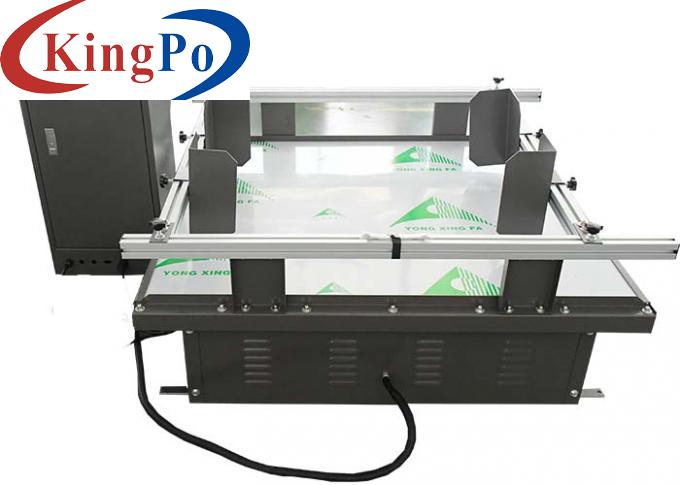

Camera Lens Rotating Torque Testing Equipment PLC Control 0.2N.M

Products Description

Camera Lens Rotating Torque Testing Equipment

Product overview:

The testing machine is designed and manufactured strictly according to customer's specific requirements. It is driven by Panasonic servo motor, equipped with Mitsubishi PLC, 7-inch touch screen. It is a dedicated high-end torque test equipment with threaded lens sleeve.

This testing machine is mainly used to verify the thread torsion strength of the lens with a threaded lens sleeve, and verify its fatigue resistance after a certain number of rotation.

Working principle:

Use a servo motor to drive the fixture holding the lens to rotate a certain number of times N (N=thread length*10/thread pitch) at a speed of not less than 20 times/min, and insert it into the corresponding threaded sleeve. The cylinder can bear a torque greater than 1.2kgf*cm through a combination of fixed pulleys and weights.

Technical Parameters:

No.:

Item

Specifications

1

2

3

Operation

4

Drive

5

1

6

7

8

9

10

11

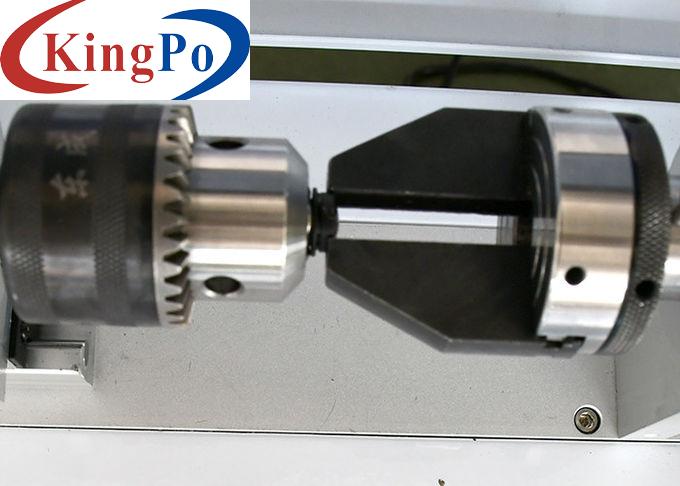

Fixture type

Input power supply

Can be customized

Electrical control

PLC

7” color touch screen

Panasonic servo motor

Test station

Clockwise Counterclockwise rotation cycles

0-999999, can be preset

Rotation speed

10-30 cycles /min

Sleeve thread specification

Provided by client

Fixture out diameter for sleeve

40mm (The radius of the torque wheel is 20mm)

Weight for torque

10N (Achieve torque 0.2N.m, greater than 1.2kgf*cm), other weights can be customized

Two types of external clamping and pin clamping, hardness ≥HRC28, smoothness higher than Ra3.2, suitable for specimens with a maximum outer diameter of less than 40mm