Products

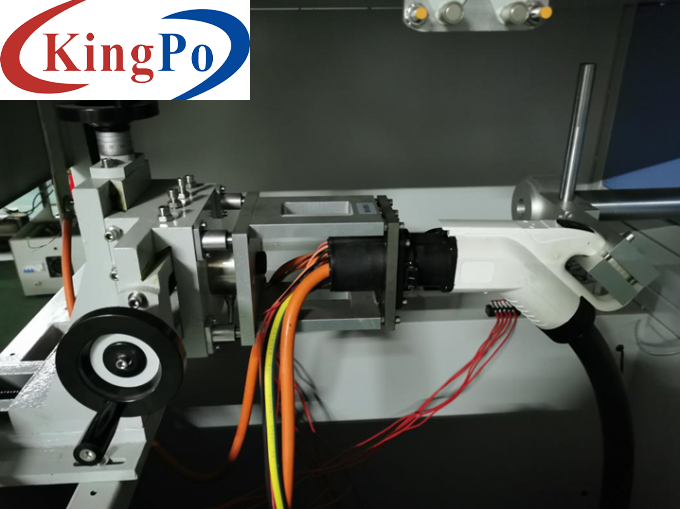

Clause 13.3.1 Mechanical Terminals Connector Rotation Vehicle Testing Equipment

Products Description

IEC 62196-1 Mechanical Tests on Terminals Vehicle Connector Rotation Test Equipment

Product information:

This mechanical tests on terminals testing equipment is required by IEC 62196-1Ed.4CDV 2020 clause 13.3.1 fig12, table 3.

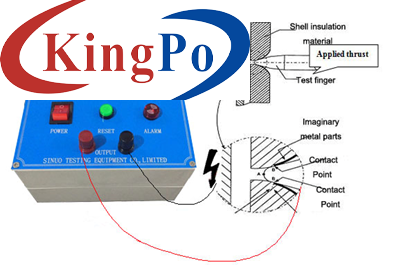

This compliance is used for judging whether the design and the structure of the clamping screw terminal is correspondent with the requirement of non over-damage to the wire. Besides, it is also used to check whether the clamping screw terminal can bear the stress during the process of normal usage.

The testing times can be preset before the test, and the compliance stops automatically with the alarm when the testing times are reached.

Technical parameters:

Test procedures (Excerpt from IEC 62196-1Ed.4CDV 2020 clause 13.3.1):

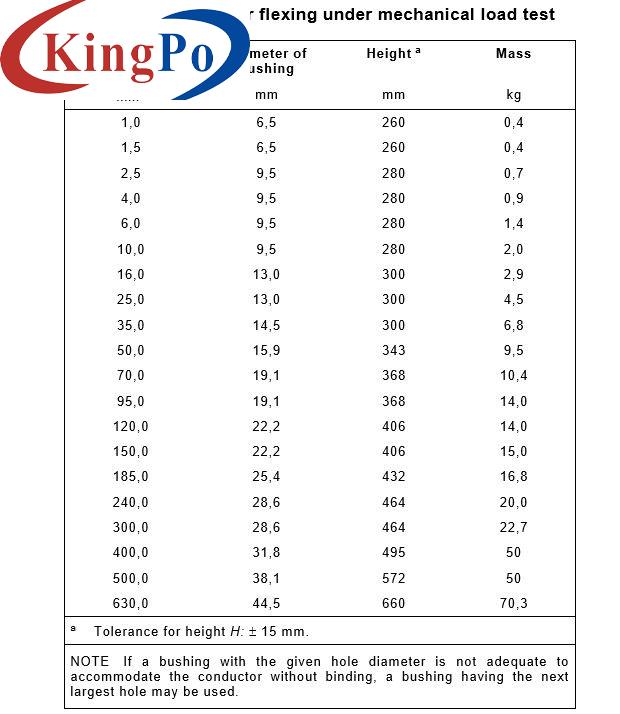

The end of the conductor is passed through an appropriate-sized bushing in a platen, positioned at a height H below the accessory, as given in Table 3. The bushing is positioned in a horizontal plane, such that its centre line describes a circle of 75 mm diameter, concentric with the centre of the clamping unit in the horizontal plane. The platen is then rotated at a rate of (10 ± 2) r/min.

Name

Item

Specification

1

Power supply

Match client’s local power supply requirements

2

Test duration

1~9999(150 times (15 min) is by default.

3

Rotation rate

(10±2) r/min

4

Mass

0.4~70.3kg (details refer to following table 3)

5

Radius of rotation

37.5mm

6

Diameter of bushing

6.5,9.5, 13,14.5,15.9,19.1,22.2,25.4,28.6, 31.8, 38.1, 44.5mm (details refer to following table 3)

7

Height

260-660mm (details refer to following table 3)

The distance between the mouth of the clamping unit and the upper surface of the bushing shall be within 15 mm of the height in Table 3. The bushing may be lubricated to prevent binding, twisting or rotation of the insulated conductor. A mass, as specified in Table 3, is suspended from the end of the conductor. The duration of the test is 15 min.