Products

Clause 25.14 Of IEC 60335-1 Power Cord Flexibility Test Equipment PLC Control

Products Description

Clause 25.14 Of IEC 60335-1 Power Cord Flexibility Test Equipment PLC control

Product Information:

Standard: Clause 25.14 of IEC 60335-1 Household and similar electrical appliances – Safety – Part 1: General requirements.

Application: It is used to check that the supply cord of the small household appliances (such as Coffee pot / electric iron) and lamps is adequately protected against excessive flexing where it enters the appliance.

Test sample: small household appliances, such as coffee pot, electric iron, toaster, luminaires and etc.

Feature: The test stations, test angles, load voltage can be customized. The test cycles, speed, voltage, etc., can be preset.

Technical Parameters:

Common Faults and Treatments:

1

2

5

Press down “Start” button, but the manipulators do not work.

Input Power

AC220V, 60Hz

Control Method

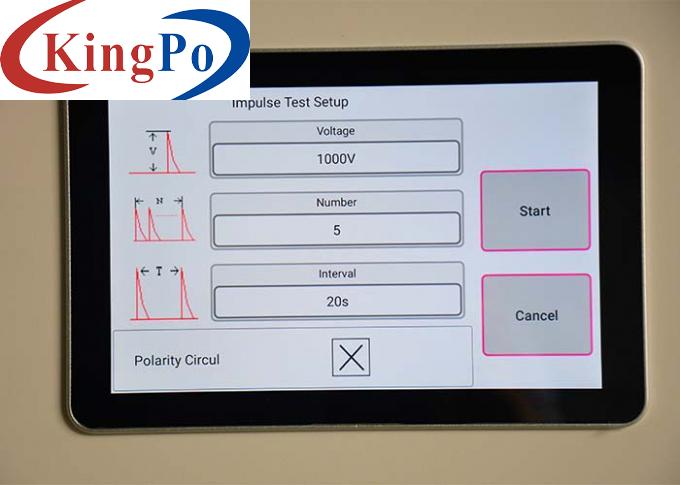

PLC control, touch screen operation

Station

One

Drive Mode

Electrical

Flexing Angle

0-360°, preset on the touch screen

Flexing Speed

0-60 cycles/min, can be preset

Test Cycles

0-999999, can be preset

Loading Weight

5N,10N

Loading Voltage

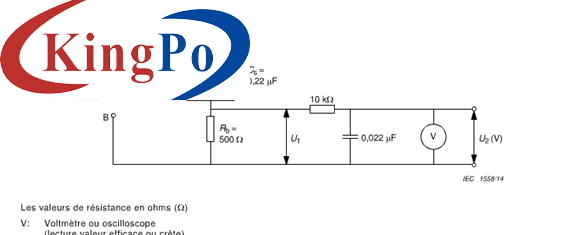

0-250V, can be regulated

Sample judgment

Judge the conduction by current

No.

Fault

Reason

Treatment

Turn on the “Power” switch, but the indicator light not turn on

The external power supply is not connected

Please connect to the external power supply

The fuse is broken

Find out the reason and change the fuse.

The indicator light damaged

Replace the light

Turn on the “Power” switch, Touchscreen not work

The internal DC24V power supply is in problem

Replace the DC24V power supply

Touchscreen damaged

Replace the touchscreen

3

Touchscreen no response

Connection to PLC loose

Reconnect

Touchscreen damaged

Replace the touchscreen

4

Load power no power supply

Load socket damaged

Replace the socket

The fuse is broken

Change the fuse

The display value and preset value of test times are the same

Press “Count Cleared” button

The E-STOP button is not reset

Release E-STOP button

There is foreign object in the machine, the machinery is stuck

Remove the foreign object

It is not under auto test mode

Press “Start” button

Connection to motor loosen

Reconnect

Not in starting position

Homing

6

Noise

Swivel speed low or too high

Reset the speed

Connection to motor loosen

Reconnect