Products

Clause Y.2 And Annex C Water Cooled Xenon Weathering Test Chamber IEC 62368-1

Products Description

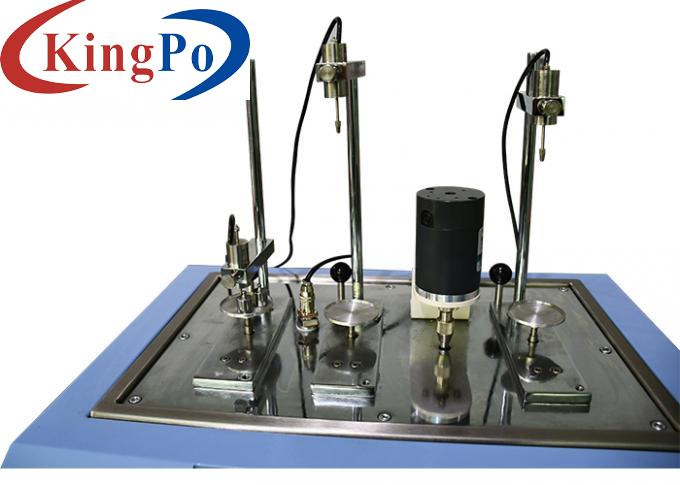

IEC 62368-1 Clause Y.2 and Annex C Water-Cooled Xenon Weathering Test Chamber

Product Information:

This Water-Cooled Xenon Weathering Test Chamber is designed and manufactured according to the standard requirements of IEC 62368-1:2018 clause Y.2 and Annex C, etc. It is with imported Q-LAB water-cooled xenon-arc lamp, spectral irradiance 0.3W/m2~1.1 W/m2 (@340nm), together with other imported high quality components, the chamber’s quality is much higher than other versions of xenon weathering test chambers in the markets.

Technical Parameters:

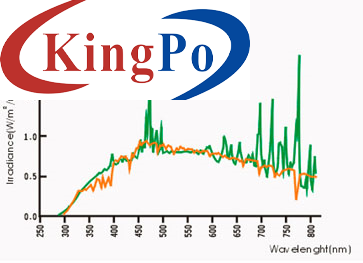

0.3W/m2~1.1 W/m2(@340nm)

40 W/m2~120 W/m2(@300nm~400nm)

Blackboard temperature: 40℃~110℃

Black mark temperature:40℃~120℃

When illuminated: 30%RH~75%RH (related to temperature)

In the dark: up to 100%RH

Free combination of light, darkness and water spray

Note: the water spray can be performed or not, if water spray is not used as per IEC 62368-1 Annex C.2.4, operator can set the spray time to be “0”.

Conforms to SAE J2412, SAE J2527, ASTMG 155ISO 105-B02, ISO 105-B04, ISO 105-B06, ISO 4892-2-A, ISO 11341-1, and etc.

With 4 custom methods, users can set test parameters by themselves to meet most common standard requirements.

Chamber overview:

Comparison of xenon lamp spectrum and solar spectrum

Control system:

Comprehensive and easy-to-use human-machine interface (Will be in English)

Applied standard

IEC 62368-1

Applied clause

Y.2 and Annex C

Dimensions

124cm×114cm×202cm (W×D×H)

Exposure area

6500cm2/ About 65 standard samples (140mm×70mm)

Light source

6.5kW long arc water-cooled xenon lamp (imported from the United States Q-LAB)

Light source life

About 2000h (based on irradiance 0.51W/m2 @340nm)

Irradiance display band

340nm, 420nm, 300~400nm optional

Irradiance range

Sample temperature

Temperature in the chamber

38℃~80℃

Humidity in the chamber

Test Conditions

Supported test standards

Applications

This is a weatherproof test chamber that uses a long arc water-cooled xenon lamp as the light source. It can provide corresponding environmental simulation and accelerated aging test for scientific research, product development and quality control. Widely used in industries such as automotive materials, plastics, packaging, coatings, inks, dyes, stabilizers, textiles, electronics and electrical appliances.

Features

HMI