Products

Compression Testing Apparatus With 150N 300N For VDE Plug Sockets Test IEC 60884-1

Products Description

Compression Testing Apparatus With 150N And 300N For VDE Plug Sockets Test IEC 60884-1

Product Information:

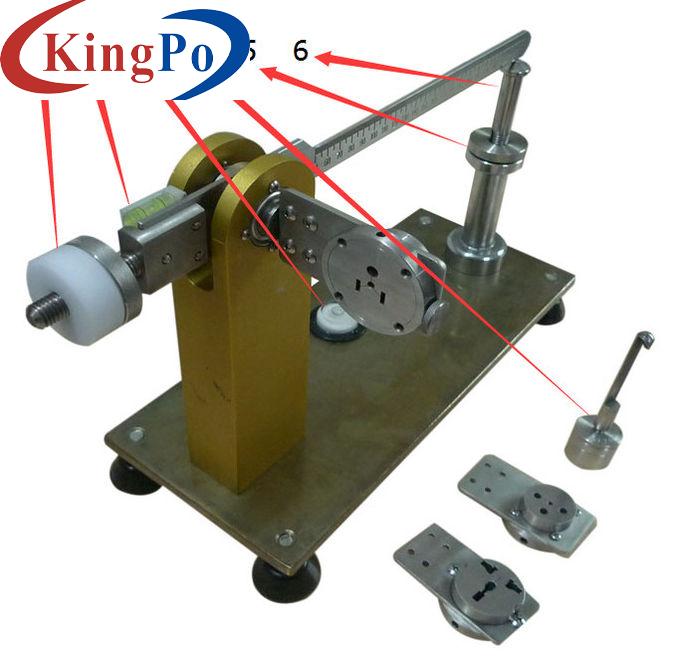

The specimens are subjected to a compression test as shown in figure 8 of IEC 60884- 1:2013, the temperature of the pressure plate, of the base and of the specimens being (23±2) ℃ and the force applied being 300 N.

The specimens are first placed in position a), as shown in figure 8 of IEC 60884-1, and the force is applied for 1 min. They are then placed in position b), as shown in figure 8 of IEC 60884-1, and again subjected to the force for 1 min.

The specimens are removed from the test apparatus and after 15 min they shall show no damage within the meaning of this standard.

Features:

A compression testing apparatus for VDE type plugs and sockets is a specialized equipment used to perform compression tests on electrical plugs and sockets that comply with VDE (Verband der Elektrotechnik, Elektronik und Informationstechnik) standards. These tests assess the mechanical strength and durability of the plugs and sockets by subjecting them to controlled compression forces. Here are the key features and components typically found in a compression testing apparatus for VDE type plugs and sockets:

Test Fixture: The apparatus includes a test fixture specifically designed to hold the VDE type plugs and sockets during the compression test. The fixture securely positions the device to ensure accurate and repeatable test results.

Compression Force Application: The apparatus applies controlled compression forces to the plugs and sockets. This force application is typically achieved using hydraulic, pneumatic, or mechanical means. The force can be adjusted to simulate various compression scenarios, including normal use or abnormal conditions.

Force Measurement: The apparatus incorporates force measurement capabilities to accurately measure the applied compression force. This measurement ensures that the force is within the specified range and allows for the evaluation of the device's mechanical strength and resistance to deformation.

Test Speed Control: Some compression testing apparatuses offer adjustable test speed control, allowing operators to control the rate at which the compression force is applied. This control feature enables the simulation of different loading rates and assesses the device's response to varying compression speeds.

Force Monitoring and Data Logging: The apparatus may have force monitoring and data logging capabilities to record and analyze the compression force data during the test. This data can be useful for evaluating the device's performance, analyzing the behavior under load, and comparing it against the specified requirements or industry standards.

Safety Measures: Safety features are essential in a compression testing apparatus to protect operators and prevent any potential hazards during testing. These measures may include safety enclosures, interlocks, or guarding systems to ensure safe operation and minimize the risk of injury.

Compliance with Standards: The compression testing apparatus is designed to comply with specific standards, such as VDE standards or related international standards, to ensure accurate and reliable test results. Compliance ensures that the apparatus is capable of conducting tests that align with the requirements defined by the relevant standards organization.

The compression testing apparatus for VDE type plugs and sockets is used by manufacturers, testing laboratories, and certification bodies to ensure that electrical plugs and sockets meet the mechanical integrity and durability requirements outlined by VDE and other applicable standards. By subjecting the devices to controlled compression forces, the apparatus helps identify any weaknesses, deformation, or failure points, enabling manufacturers to improve their designs and ensure the safety and reliability of the products.

Technical Parameters:

Test method:

1. Put the apparatus in a constant temperature environment for testing, and keep the temperature of the pressure plate, base and sample at 23±2℃.

2. Rotate the handle to lift the weight, place the sample directly under the pressing block as shown in Figure a below, rotate the handle to lower the weight, make the sample bear a force of 300N, and start timing for 1min.

3. After 1min, place the sample as shown in Figure b, and bear the force of 300N again for 1min.

4. After the sample is removed from the test device for 15 minutes, the sample should not appear damaged within the standard meaning.

Number of Test Station

1

Operating method

By manual

Weight

150N and 300N (consists of 2 pc of 150N weight)

Conforms to standard

IEC 60884-1 Clause 10.1, Clause 24.5, Fig8