Products

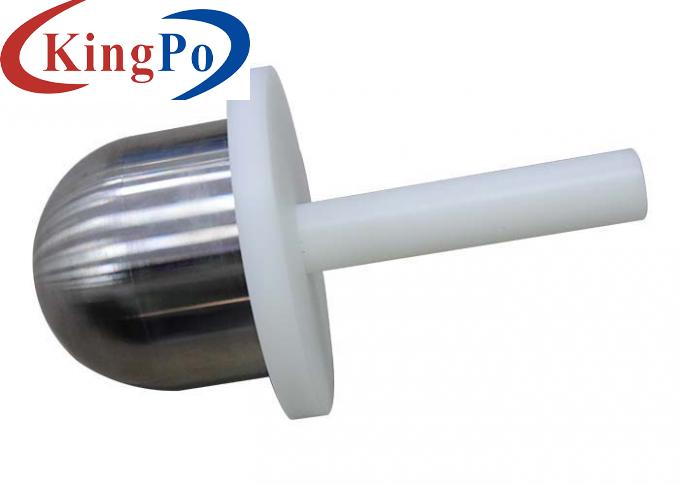

Conductors Undue Damage Checking Test Apparatus 10±2 RPM IEC 60884-1 Figure 11

Products Description

IEC 60884-1 Figure 11 Conductors Undue Damage Checking Test Apparatus

Standard: IEC60884-1 clause 12.2.5, figure 11.

Application: It is used to check terminals with screw clamping shall be so designed and constructed that they clamp the conductor(s) without undue damage to the conductor(s).

Test sample: Plugs and socket-outlets terminals.

Technical Parameters:

Test processes:

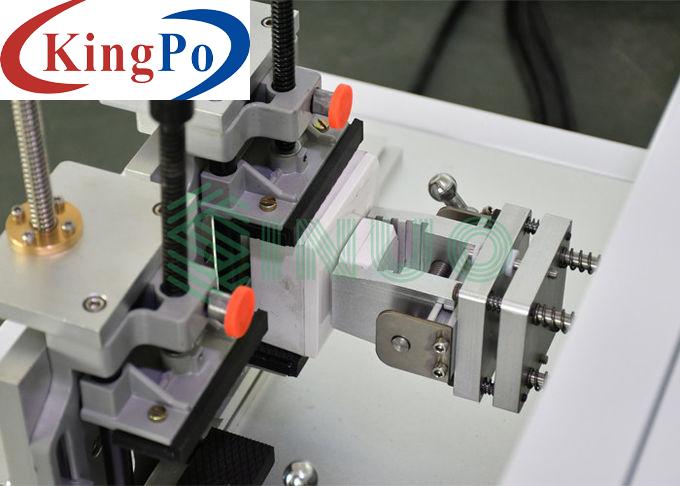

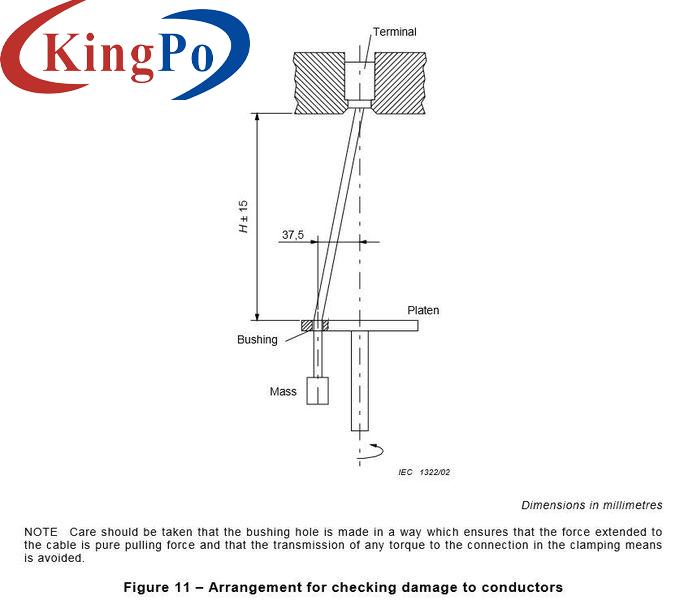

The terminal is placed in the test apparatus according to figure 11 and fitted with rigid, solid, stranded and/or flexible conductor(s), according to table 3 first with the smallest and then with the largest nominal cross-sectional area, the clamping screw(s) or nut(s) being tightened with the torque according to table 6.

Where rigid stranded conductors do not exist, the test may be made with rigid solid conductors only. In this case, there is no need for further tests.

Comparison table of the weight, height and bushing as below:

Diameter of bushing Hole

( mm)

Model

SN2111

Test rate

10±2 RPM

Diameter of gyration

75mm

Test times

0~9999

Test weights

0.3, 0.4, 0.7, 0.9, 1.4, 2kg

Test height

260, 280, 300, 320mm

Diameter of bushing

6.5, 9.5, 13, 14.5mm

Complied standards

IEC60884-1, IEC60669-1

The length of the test conductor shall be 75 mm longer than the height (H) specified in table 9.

The end of the conductor is passed through an appropriate bushing in a plate positioned at a height (H) below the equipment, as given in table 9. The bushing is positioned in a horizontal plane such that its centre line describes a circle of 75 mm diameter, concentric with the centre of the clamping unit in the horizontal plane; the platen is then rotated at a rate of (10 ± 2) r/min.

The distance between the mouth of the clamping unit and the upper surface of the bushing shall be within ±15 mm of the height specified in table 9. The bushing may be lubricated to prevent binding, twisting, or rotation of the insulated conductor.

A mass as specified in table 9 is suspended from the end of the conductor. The duration of the test is approximately 15 min.

During the test, the conductor shall neither slip out of the clamping unit nor break near the clamping unit, nor shall the conductor be damaged in such a way as to render it unfit for further use.

Nominal cross-sectional area of conductor ( mm²)

Height (mm)

Mass for conductor (kg)

0.5

6.5

260

0.3

0.75

6.5

260

0.4

1.0

6.5

260

0.4

1.5

6.5

260

0.4

2.5

9.5

280

0.7

4.0

9.5

280

0.9

6.0

9.5

280

1.4

10.0

9.5

280

2.0

16.0

13.0

300

2.9