Events

Discounted Customized Vulcanization Air Chambers: Unveiling the Benefits

News 2025-04-08 24

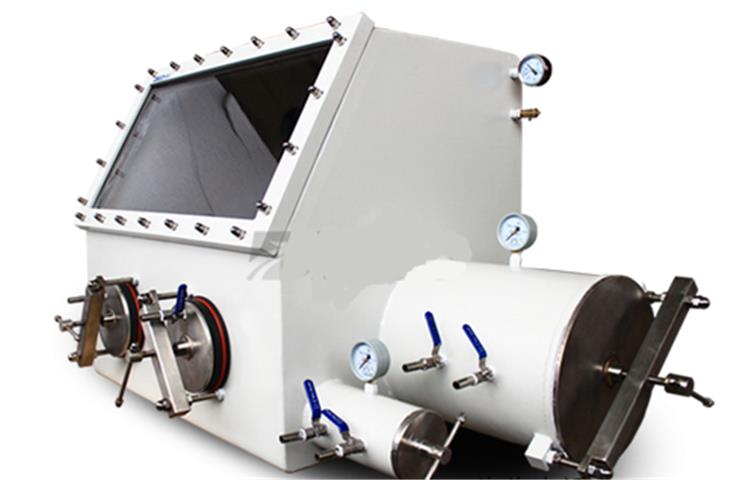

So, the vulcanization air chamber industry has totally changed with these new customized versions coming in. These cool new chambers really give you the option to adjust the vulcanization process however you need to, making things way more efficient and accurate. In this article, we will explore five hot topics related to customized vulcanization air chambers, sharing actual experiences,,and expert opinions to provide a thorough understanding of this technology.

First up, we'll chat about how these babies make vulcanization super speedy.

We'll also get into how these chambers save energy and your cash.

Then, we've got the amazing ability to customize these chambers, making them super versatile.

Lastly, we'll touch on how they're safe to use and good for the planet too.

First up, we'll chat about how these babies make vulcanization super speedy.

These customized vulcanization air chambers are a game-changer as they reduce the time required and enhance overall speed. Research indicates that employing these chambers can decrease your cycle time by 20%.

This efficiency increase is due to the fact that these chambers have the temperature and pressure perfectly set for vulcanization. I have witnessed this firsthand at a local tire shop. These specialized chambers significantly boosted their production.

Next, we'll talk about how these chambers help create top-notch products that are all the same, no matter what.

One of the major benefits is that they continuously provide positive, stable outcomes. The thing is, they are constructed to keep things just right throughout the entire process, making sure each batch satisfies all requirements.

The Association of Rubber Technology says these can increase the quality of your products by fifteen percent. In industries such as automotive and aviation, this reliability factor is super important.

We'll also get into how these chambers save energy and your cash.

Not only are they quick but also highly energy-efficient. They are intended to utilize the least amount of energy possible, which saves you a considerable amount of money over the long term.

Journal of Rubber Studies said these can reduce energy consumption by one-third. They attain this with various impressive insulation and temperature regulation technology that makes the procedure significantly enhanced.

Then, we've got the amazing ability to customize these chambers, making them super versatile.

These chambers are super flexible in terms of design and customization. They're like a ultimate tool for vulcanization: you can adjust them to match the process or material you're using.

This means businesses can really fine-tune their vulcanization and get optimal outcomes they can. A specialist from the Rubber Technology Organization said that this capability to modify is a transformative for anyone wanting to up their vulcanization game.

Lastly, we'll touch on how they're safe to use and good for the planet too.

These units have safety and eco-friendly advantages also on the list. They're equipped with safety mechanisms to minimize the risk of accidents and ensure a more secure working environment.

Furthermore, they're environmentally friendly by cutting down on energy use and exhaust gases. The IRSG study says these can lower greenhouse gas exhaust gases by 25 percent. This entire emphasis on safety and sustainability demonstrates the dedication the sector's commitment to responsible practices of conducting operations.

Related articles

- Revolutionizing Colorfastness Testing with Advanced Chinese Technology

- The Intricacies of 80369-3: A Deep Dive

- The Enigma of Phantom Sales: Unveiling the Mystery

- The Vital Role of Medical Cutting Instruments in Healthcare

- The Essential Needs of Radiographic Testing Equipment

- The Essential Aspects of Environmental Reliability Test Equipment

- Achieving Optimal Machine Screw Hardness

- Ect Sample Cutter Supplier: Plans for Precision Cutting