Events

Discounts on Top Color Fastness Rubbing Tester Manufacturers

News 2025-04-15 19

You know, operating an outstanding color fastness tester business, I totally get how crucial quality testing equipment is for the textile industry. So, in this piece, I'm gonna jump into the top five things people always ask about our stuff. I'll give you the dirt on it and throw in some stories from my experience in this game.

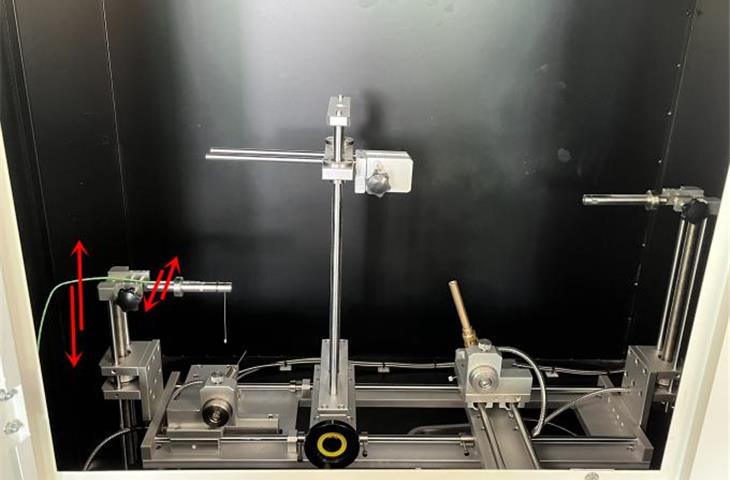

Alright, let's start with the basics: What's a color fastness rubbing tester, you ask? A color fastness rubbing tester is an essential tool for the textile industry. It checks How dyes and colors endure to different types of rubbing. This test ensures that whatever they make is of high quality and that the colors stay nice even after extensive use or extended time in use.

Over the years, I've faced all sorts of challenges when making these testers. The most significant challenge was making sure the testers were extremely reliable and highly accurate.

We accomplished it using cutting-edge technology and extremely rigorous quality control. For example, we use high-grade materials to build them so they can cope with the demanding lab conditions. Also, our team keeps a close eye on them to make sure they're always giving reliable outcomes.

Now, how do you pick the right tester for your needs? selecting the appropriate tester is key for getting good results. Think about what kind of fabric you are working with, the required testing criteria, and the frequency of your use. Our expert team is here to help you pick the best tester for you. Like, one time a client needed a tester for their silk stuff. We looked at what they needed and suggested our silk tester. It worked great for them and helped them achieve their quality objectives.

Are these color fastness testers good for the environment? We're eco-friendly at our company. We make sure our testers are energy-efficient and utilize environmentally conscious materials. And we give you all the maintenance advice to keep your stuff running and reduce waste. Our commitment to sustainability has us respected in the industry.

So, how often should I tweak my color fastness tester? You require to standardize your tester consistently in order to maintain it precise and dependable. Typically, every six months up to a year should suffice. I have instructed numerous clients how to standardize these devices so that so that they can maintain their machinery operating smoothly.

Can I get a discount if I buy a bunch of these? Certainly, we offer rebates on bulk purchases. We understand it revolves around receiving the most value for your money, therefore we strive to provide you with the most favorable offer. For a certain client, we created a customized order which satisfied their requirements and provided them with a substantial reduction, so that they could acquire additional devices without exceeding their budget.

Related articles

- Surgical Cutting Instruments: Essential Purchases

- Optimizing Product Inspection for China Wholesale

- Revolutionizing Visual Media: The Role of 4K Ultra-HD Uncompressed Signal Generators

- Unveiling the Essence of Wear Resistance Testing

- The Vital Role of Test Bench Equipment

- The Essential Role of Testing Equipment Calibration Companies

- The Essential Guide to Forming Sheet Metal

- The Pivotal Role of Meltblown Nonwoven Fabric Machines in Modern Manufacturing