Products

Electrical Beauty Care Appliance Vacuum Pressure Testing Equipment

Products Description

IEC 60335-2-113 Beauty Care Appliance Outlet Air Pressure Test Machine

Product overview:

This vacuum pressure test system for beauty care appliances conforms to IEC 60335-2-113: 2016. It is suitable for verifying the outlet air vacuum pressure of appliances with vacuum or negative pressure function in electrical skin stimulators, and it shall not be greater than the vacuum pressure required by the standard to protect the human body from damage.

Working principle:

It uses a vacuum gauge to monitor the pressure change of the vacuum box of the rated volume and measure the suction force of the appliance.

Technical Parameters:

Electronic control part: Mitsubishi PLC with module, Weinview7-inch color touch screen, Omron relay, Chint switch, etc.

Pneumatic part: Meacon controlled differential pressure sensor, Airtac solenoid valve, pipeline, joint, etc.

Mechanical part: high tightness stainless steel vacuum box, integrated machine

Test station

Single station

Electrical control method

PLC intelligent integrated control, 7-inch color man-machine touch interface operation

Vacuum box size

Ф50×100mm

Vacuum pressure reading method

The real-time data is read by the differential pressure sensor and displayed on the touch screen, then the system automatically makes a qualified judgment after reaching a stable

Sample connection method

Manually sealed joint connection, two standard configurations, switchable

Operation process

The vacuum pressure parameter is preset to 75.0kPa, the sample suction port is connected with a sealed joint, and the sample power is turned on. When the fluctuation range of the vacuum degree is less than the set value, the system automatically makes a qualified or unqualified judgment, the corresponding indicator light is on. Then the vacuum box is filled with the atmosphere automatically, the sample is removed from the test equipment, the test is completed.

System configuration

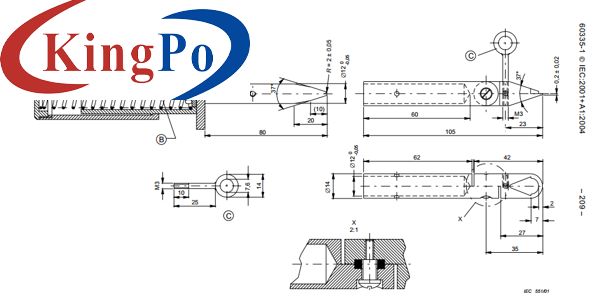

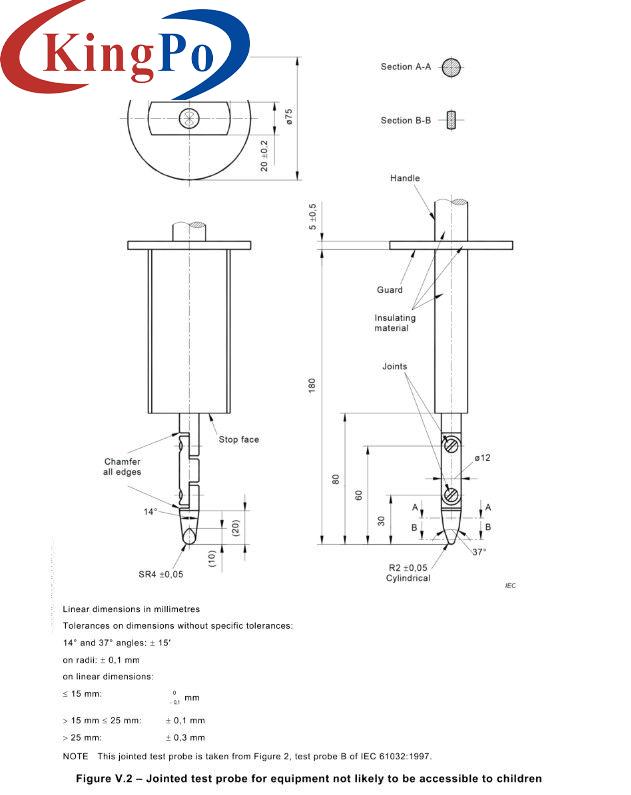

Test principle diagram