Events

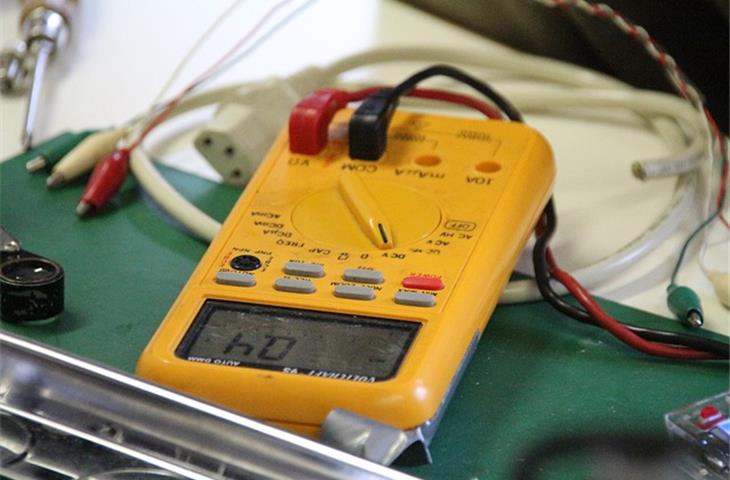

Essential Wire and Cable Testing Equipment: Who Needs What?

News 2025-01-08 72

trusted wire and cable testing machinery is of utmost importance in the realm of power and IT sectors.Electrical systems' efficiency, security, and functionality are crucially ensured by these tools.Having the right testing equipment is essential for production, setup, upkeep, or error resolution.

This article will explore the various types of wire and cable testing equipment available, discussing the specific needs that arise in different scenarios.Cable Fault Locators are devices used to locate faults in cables, such as breaks or shorts, by detecting resistance alterations in the cable.Connection Testers are used to check the power link between two points in a wire or cable.

Insulation Quality Meters are used to assess the resistance level between the conductors of a wire or cable and its surrounding insulation.Communication Analyzers are used to measure the performance of signal pathways, such as cables and antennas.Power setups must comply with security protocols and rules, ensuring safety and conformity.

testing apparatus for wires and cables is essential for ensuring these specifications in installations, thereby minimizing the chance of incidents and ensuring adherence to industrial norms.manufacturers require to ensure that the wire and cable products they produce fulfill the necessary requirements, which is manufacturing quality assurance.

Defects, such as frayed wires or insufficient protection, are identified by testing equipment, which allows manufacturers to make necessary corrections before the products reach the market.In the field, electricians and engineers often encounter problems with wire and cable installations, which relates to problem-solving and upkeep.

sufficient testing devices enables electricians and engineers to efficiently locate the primary reason for the problem, streamlining time and resources in problem-solving and upkeep activities.Regular testing of wire and cable installations helps in supervising their operation over time, which is operational oversight.

this data is important for detecting possible problems before they turn serious, thereby guaranteeing the durability and dependability of the power systems.Various testing apparatus is appropriate for diverse uses, which requires the consideration of the use.For example, cable fault detectors are perfect for telecommunication and computer networks, while network analysis tools are more fitting for transmission line operation analysis, which are particular applications.

Trustworthy testing equipment is essential for precise outcomes, which ensures accuracy and dependability.Seek brands with reputation known for manufacturing premium-grade products, which are unlikely to malfunction during critical tests.Field engineers frequently have to transport their testing instruments to various locations, which needs consideration for portability and user-friendliness.

Consider the carryability and user-friendliness of the gear, as well as the availability of instruction and tech assistance, which are important aspects of the gear.Ensure that the testing gear is compatible with the types of wire and cable installations you work with, which is a factor of suitability and scalability.

Additionally, consider whether the gear can be expanded or upgraded as technology advances, which is also part of suitability and scalability.The electronics and telecommunication sectors rely on wire and cable testing gear as a essential part.experts can choose the appropriate devices for their assignments by realization the multiple varieties of testing gear accessible and the unique requirements that arise in unique situations.

Ensuring safeguard, standard, and efficiency, as well as addressing diagnosis and care requirements, all depend on having the right testing gear accessible.

Related articles

- How to Choose the Right Leather Contraction Temperature Tester Supplier

- ISO 9000 9001: A Comprehensive Guide to Quality Management

- The Comprehensive Guide to Displacement Vibration Test Systems Factory

- The Essential Abrader: A Comprehensive Guide

- What You Need to Know About ISO 594 Luer Gauges

- Decoding EN 60204-1:2018 Standards for Machine Tools

- Why ECT Sample Cutter is Essential for Precision Cutting

- Where Hail Impact Testing Excels in Automotive Safety