Products

EV Plug Electronic Lock Test Equipment For Charging Interfaces Plugs And Sockets Testing

Products Description

EV Plug Electronic Lock Test Equipment For Charging Interfaces Plugs And Sockets Testing

Product information:

The test machine is used to test whether electrical accessories with electronic locking devices such as electric vehicle charging interfaces, industrial plugs and sockets, and couplers can withstand the mechanical stress, electrical stress, and thermal stress that occur during normal use without excessive wear or other harmful effects. The purpose is to verify its reliability.

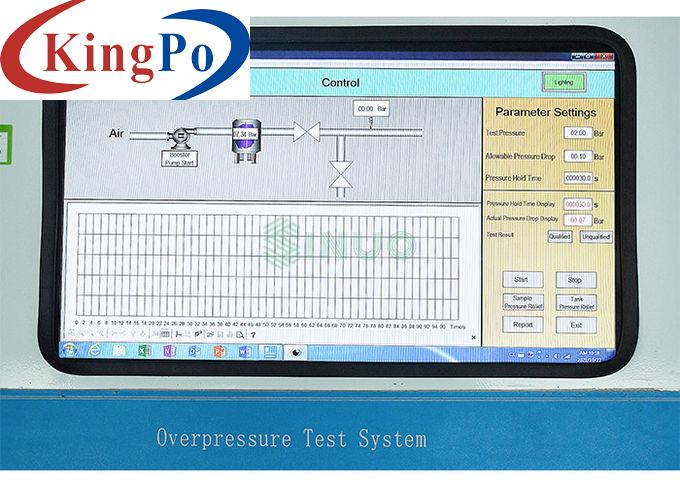

The servo motor drive mechanism is used to apply force to the electronic locking mechanism of the sample. In cooperation with the electronic control mechanism, the electronic locking mechanism can be tested for normal operation, emergency unlocking, extreme condition cycle life and mechanical strength. The power-on and power-off time, test speed and stroke can all be preset through the touch screen.

It adopts an integral frame. It is driven by a servo motor, precision ball screw and synchronous belt. It has a color touch screen for humanized operation and powerful digital display function. It has a PLC intelligent control system. It also adopts a three-axis adjustable fixture. It is suitable for comprehensive testing of the electronic locking device of the charging gun.

Technical parameters:

a) Normal operation (service life) test of electronic locking device

b) Manual emergency unlocking test of electronic locking device

c) Cycle life of electronic locking device under extreme conditions

d) Structural strength test of electronic locking device

a) Meet the requirements of independent electronic locking device fixture or universal fixture;

b) Meet the requirements of national standard, American standard, European standard AC and DC charging interface universal fixture

Test items

Workstation

Single station

Electrical control mode

Mitsubishi PLC intelligent integrated control, 7-inch color human-machine touch interface operation

Operation mode

Manual or program-controlled operation

Fixture

Test function

Equipped with push rod type electronic lock test function

Electronic locking device unlocking

It is capable of manually unlocking the electronic locking device and adopts an electronically controlled automatic operation mode. It is programmed to meet the normal operation (service life) requirements of the electronic locking device. The unlocking force requirement meets (0~50) N. The indication error is ≤±0.5%F.S., and the resolution is ≤0.1N.

Electronic locking device force

Equipped with a force-applying device for the locking rod mechanism of the electronic locking device. The force-applying device can clamp the end of the locking rod and apply axial thrust or tension. The force measurement range is required to meet (0~50) N. The indication error is ≤±0.5%F.S., and the resolution is ≤0.1N. The force-applying rate can be adjusted and the force value can be kept constant. The force-applying device can measure the displacement of the force-bearing part and the position status of the locking rod. The displacement measurement range meets (0~50) mm. The indication error is ≤±0.02mm, and the resolution is ≤0.01mm.

Polarity conversion

The PLC program switches automatically. And it switches 1s after monitoring the electronic lock status feedback.

Switch power supply

(0~24) VDC is adjustable, the voltage accuracy is better than 0.5 level, and the resolution is ≤0.1V.

Forward conduction

(0~5000) ms can be set arbitrarily, and the resolution is ≤1ms.

Reverse conduction

(0~5000) ms can be set arbitrarily, and the resolution is ≤1ms.

Interval time

Can be set arbitrarily within the range of (0~200) s. Resolution ≤1s. 1-200mA adjustable, load current coordinated action.

Function

Configured with 1-200mA adjustable load current. Equipped with a monitoring device to feedback the unlocking/locking signal of the electronic lock. Record the on-off status and number of signals.

Fault judgment

Built-in signal feedback judgment, automatic shutdown when abnormality occurs.

Number of tests

(0~99999) times can be set arbitrarily.

Safety protection

Ground protection, short circuit protection, overload protection.

Power sypply

Power supply: AC380V±10%/50-60Hz, 5kW

Equipment dimension and weight

Dimensions: about W1000*D900*H1400mm; Weight: about 200kg