Products

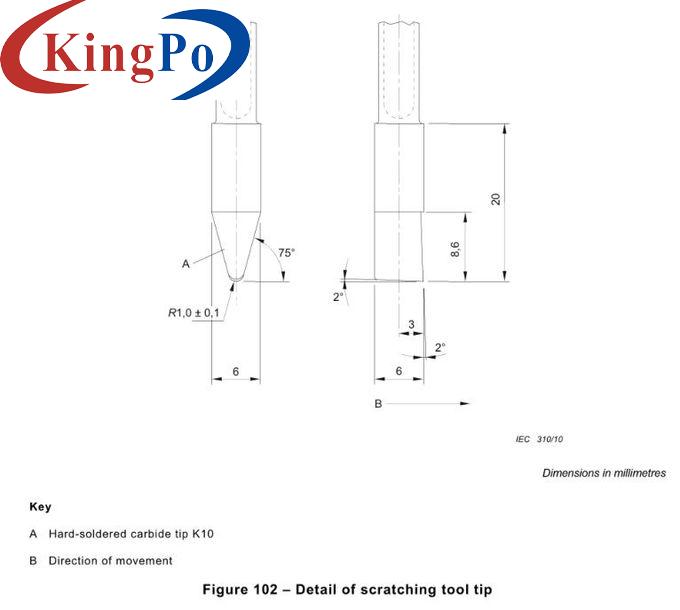

Figure 102 Hard - Soldered Carbide Tip K10 Refrigerator Scratching Tool Tip IEC60335-2-24

Products Description

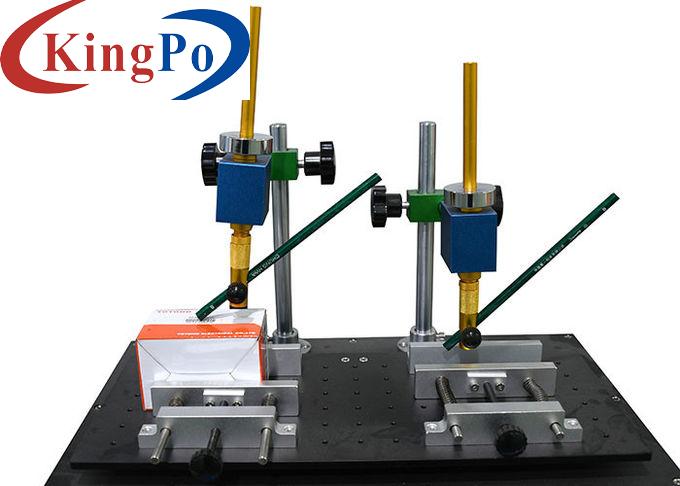

IEC60335-2-24 Figure 102 Hard-soldered Carbide Tip K10 Refrigerator Scratching Tool Tip

Standards & Clauses:

Conforms to IEC60335-2-24 clause 22.107.2 Figure 102 and etc.

Samples and Restrictions:

All accessible surfaces of protected cooling system components, including accessible surfaces in intimate contact with protected cooling systems.

Test Process:

All accessible surfaces of protected cooling system components, including accessible surfaces in intimate contact with protected cooling systems, are scratched using the tool whose tip us shown in Figure 102.

The tool is applied using the following parameters:

- force at right angles to the surface to be tested........................35N±3N;

- force parallel to the surface to be tested............not exceeding 250N.

The tool is drawn across the surface to be tested at a rate of approximately 1mm/s.

The surface to be tested is scratched at three different positions in a direction at right angles to the axis of the channel and at three different positions on the channel in a direction parallel to it. In the latter case, the length of the scratch be approximately 50mm.

Structure: