Products

Hot Wire Coil Ignition Flammability Test Chamber For Solid Electrical Insulating Materials IEC 60IEC60695-2-20

Products Description

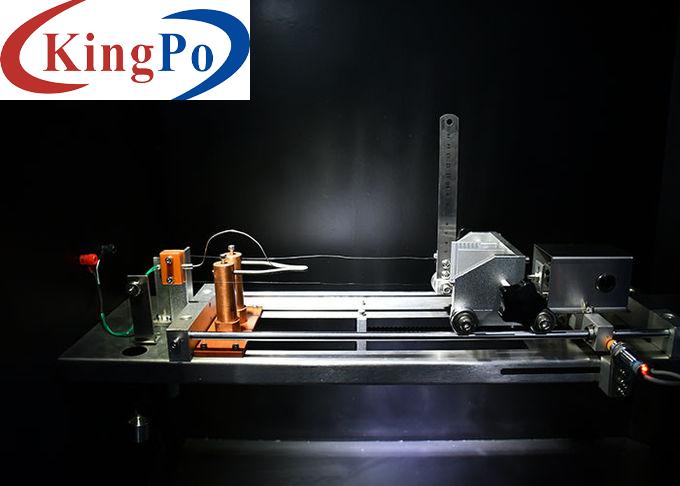

IEC 60IEC60695-2-20 Hot Wire Coil Ignition Test Apparatus for Solid Electrical Insulating Materials

Overview:

Hot wire ignition test apparatus conforms to IEC60695-2-20-1995, ASTMD3874-1997, IEC60950-1999, UL746A-2000, UL746C-2000, IEC829-1998.

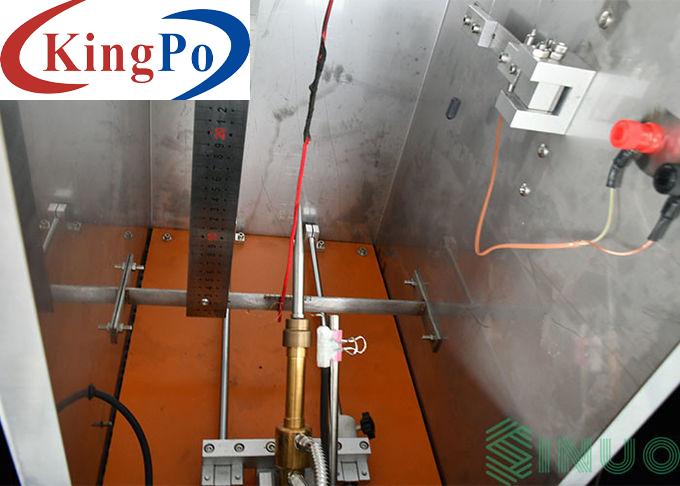

This chamber has a black background inside, with ventilation and lighting device, the time and power can be digital displayed, with large observation window for observation and recording conveniently, high quality components ensure the stability and accuracy of the testing.

Working Principle:

Hot wire ignition test use specific size (0.5mm length 250mm) specific material (Ni80/Cr20) electric wire, after pre-annealing required heating power (0.26W/mm) and the specified time (8s ~ 12s), winding 5 full circle on the sample according to a certain in winding tension (5.4N) and winding pitch (6.35mm), test the specimen wounded by electric wire to 120s under the provisions of the heating power (0.26W/mm), assessment the specimen's fire risk according to the test result whether it is ignited and the ignition time.

Technical Parameters:

250mm

5.4N ± 0.2N, 6.35mm ± 0.5mm (within 31.5mm ± 0.5mm, wind 5 full circle)

the 120s (the 1s ~~ 999.9s number was preset) 0.26W/mm ± 0.01W/mm (digital display can be adjusted)

What kinds of materials can be tested by hot wire based test methods:

It is applicable to solid electrical insulating materials. It is intended to provide a relative comparisonof the behaviour of various materials according to the time taken to ignite the specimen during application of heat from an electrically heated coil as an ignition source.

The test method is not valid for determining the ignition behaviour of complete items of equipment, since the dimensions of the insulating systems or combustible parts, the design and heat transfer to adjacent metallic or non-metallic parts, etc. greatly influence the ignitability of the electrical insulating materials used therein. In addition to this, it is not valid for determinng fire behaviour and fire hazard of equipment.

Input power

220V/50Hz or 110V/60Hz can be customized

Output Power

10V, 30A, 300W

Electric wire

Ø 0.5mm, Ni80/Cr20, length: 250 mm ± 5mm, cold resistance: 5.28Ω / m

Annealing bracket spacing

Test article bracket spacing and height

70mm, 60mm high

Winding tension and winding pitch

Annealing time and power

8s ~ 12s (1s ~~ 999.9s significant number can be preset) ± 4% 0.26W/mm (digital adjustable)

Test time and power

Size of the test sample length

(125mm ± 5mm) × width (13.0mm ± 0.3mm) × thickness (3.0mm-12mm) ± 0.1mm

Test area volume

>0.5³(can be costumed 0.75³,1³)