Products

IEC 60065 2014 Clause 9.1.7 Enclosure Openings Unjointed Test Probe 11

Products Description

IEC 60065:2014 Clause 9.1.7 Enclosure Openings Unjointed Test Probe 11

Product Overview:

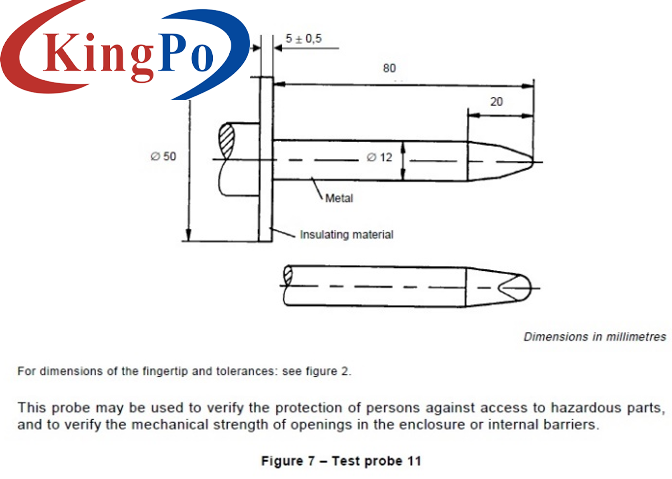

This probe conforms to the standard requirements of IEC 60065:2014 clause 9.1.7, IEC61032 fig.7 test probe 11, etc. This probe may be used to verify the protection of persons against access to hazardous parts and to verify the mechanical strength of openings in the enclosure of internal barriers.

Probe Dimension:

Conforms to IEC61032 fig.7 test probe 11

Please refer to the relevant standards.

Take IEC 60065:2014 clause 9.1.7 as an example:

The enclosure of the apparatus shall be sufficiently resistant to external forces. Compliance is checked by the following tests:

by means of a rigid test finger according to IEC 61032:1997, test probe 11, a force of

50 N ± 5 N, directed inwards, is applied for 10 s to different points of the enclosure

including openings and textile coverings.

The force shall be so exerted by the tip of the test finger as to avoid wedge or lever action.

During the test, the enclosure shall not become HAZARDOUS LIVE, HAZARDOUS LIVE parts

shall not become ACCESSIBLE, textile coverings shall not touch HAZARDOUS LIVE parts.

The test probe doesn’t have built-in force, if specific applied force required, the test probe should work together with a force gauge. At the end of our probe handle, there is a M6 thread hole to match the force gauge. Showing as following reference picture:

Notice

1. The test probe doesn’t have built-in force, if specific applied force required, the test probe should work together with a force gauge. At the end of our probe handle, there is a M6 thread hole to match the force gauge.

2. For verifying whether LIVE PARTS touched, recommended to work with our anti-shock probe experiment device or a 40~50V voltage indicator, using one cable to wire the metal part of the probe with one terminal of the anti-shock probe experiment device, and then another cable to wire the LIVE PART of specimen with the other terminal of the anti-shock probe experiment device.

3. Please do not damage the appliance shape (such as scratching, bending, etc.).

4. Prevented from dust and moisture environment, in order to avoid the oxidation to affect the dimensional accuracy.

5. Be careful of electric shock.

Probe Tip Length (mm)

20 0 -0.05

Probe Tip Cylindrical Radius (mm)

R2±0.05

Probe Tip Spherical Radius (mm)

R4±0.05

Probe Tip Cylindrical Angle (°)

37o 0 -10’

Probe Tip Spherical Angle (°)

14 o 0 -10’

Probe Diameter (mm)

Ф12 0 -0.05

Probe Length with Tip (mm)

80±0.2

Probe Material

Stainless Steel

Guard Diameter (mm)

Ф50

Guard Thickness (mm)

5±0.5

Handle Material

Nylon

Handle Length (mm)

100