Products

IEC 60068-2-75 IK Code High Energy Pendulum Impact Test Apparatus Plug And Socket Test

Products Description

IEC 60068-2-75 IK Code High Energy Pendulum Impact Test Apparatus Plug And Socket Test

Equipment information:

The high energy pendulum impact test apparatus is designed and manufactured according to the requirements of IEC60068-2-75, IEC60884-1:2013, IEC62262:2002 clause 6, etc.

It is used for the impact resistance test of household and similar electronic and electrical products and their accessories such as plugs and sockets and wall mounted mounting boxes, screw glands, covers, switches, lamps, etc., to assess the safety performance and strength level of the products.

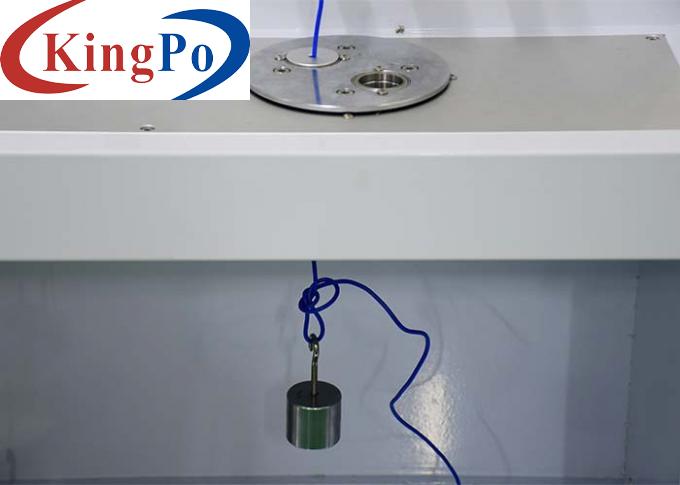

Test Eha: Pendulum Hammer, the striking element is free released at a certain height through a 1 m pendulum tube, impact the specimen at the lowest point in the vertical direction, after the conversion of gravitational potential energy to kinetic energy, to achieve the purpose of impact test on the sample.

Features:

The High Energy Pendulum Impact Test Apparatus is a specialized testing device used to evaluate the impact resistance and toughness of materials, components, or structures. This apparatus is commonly employed in industries such as automotive, aerospace, construction, and manufacturing, where impact resistance is critical for ensuring product safety and reliability.

The main components and features of a typical High Energy Pendulum Impact Test Apparatus include:

Pendulum: The apparatus consists of a heavy pendulum arm, usually made of steel or other durable materials. The pendulum is designed to store a significant amount of potential energy when raised to a certain height.

The High Energy Pendulum Impact Test Apparatus allows for controlled and repeatable impact testing, simulating real-world scenarios in which materials or components may be subjected to sudden impacts or collisions. It helps assess the ability of a material to absorb energy and resist fracture or deformation under impact loading.

It is important to follow relevant testing standards or specifications, such as ASTM, ISO, or industry-specific guidelines, when conducting impact tests using the High Energy Pendulum Impact Test Apparatus. These standards provide specific procedures, parameters, and acceptance criteria for impact testing based on the intended application or industry requirements.

Technical Parameters:

Equivalent Mass

kg

One is 9mm (it works with 2J striking element);

the other is 15.9mm (it works with 5J, 10J, 20J,50J striking elements)

Table 1 Striking element characteristics

≤1

±10%

2

±5%

5

±5%

10

±5%

20

±5%

50

±5%

Table 2 Height of Fall

Table 3 Relationship of IK code and corresponding energy

Note 1. If higher impact energy is required, the recommended value is 50J.

Note 2: Some other standards use a single digit to indicate the specified impact energy. To avoid mixing with it, the feature number is represented by two digits.

Structure:

The low energy pendulum impact test device is mount ed to the wall, the sample mounting bracket is adjustable up, down, left and right, and the angle can be adjusted by pivot, thereby achieving impacts on different positions on the front side and impacts on side of the sample.

The high-energy pendulum impact test device adopts a trolley structure, can move around left and right, the height of the upper and lower impact points is adjustable through the screw guide, the impact angle is adjustable from 0 to 90°.

Release Mechanism: A release mechanism is incorporated to enable controlled and precise release of the pendulum. This mechanism ensures consistent and repeatable impacts during testing.

Specimen Holder: The apparatus includes a specimen holder or fixture where the test sample is securely mounted. The specimen holder is designed to accommodate different sample sizes and shapes, ensuring proper alignment and stability during impact.

Energy Measurement System: The apparatus is equipped with an energy measurement system, typically including sensors or load cells, to accurately measure the impact energy delivered to the test specimen. This enables precise quantification of the impact resistance and toughness of the tested material or component.

Model No.:

SN2122B (high energy)

Energy/J

Default 2J, 5J, 10J,20J (50J is optional)

500g,1.7kg,5 kg,5 kg, (10 kg optional)

Pendulum Tube Length

Length 1000㎜

Pendulum Tube Diameter

Impact Point

Up and down adjustable, stroke: 200-1200mm, the height is customizable

Height of Fall

0-500mm, scale display

Striking Element Fix and Release

Fixed by mechanical latch, released by spring device

Mounting Brackets

Lamp mounting bracket can be optional

Energy / J

Equivalent Mass ±2%kg

0.25(0.2)

0.5

1.7

5

5

10

Material

Nylon

Steel

R/mm

10

25

25

50

50

50

D/mm

18.5(20)

35

60

80

100

125

f/mm

6.2(10)

7

10

20

20

25

r/mm

-

-

6

-

10

17

l/mm

Adjusted according to the equivalent mass, see Appendix A

Energy /J

0.14

0.2

(0.3)

0.35

(0.4)

0.5

0.7

1

2

5

10

20

50

Equivalent Mass /kg

0.25

(0.2)

0.25

(0.2)

0.25

(0.2)

(0.2)

0.25

0.25

0.25

0.5

1.7

5

5

10

Height of Fall ±1%mm

56

(100)

80

(150)

140

(200)

(250)

200

280

400

400

300

200

400

500

Note 1, see note 3.2.2; Note 2, the energy unit of this part of the joule (J) is derived from the standard gravity acceleration (g), the whole value of g round: 10m / s2.

IK Code

IK00

IK01

IK02

IK03

IK04

IK05

IK06

IK07

IK08

IK09

IK10

Energy / J

a

0.14

0.2

0.35

0.5

0.7

1

2

5

10

20

a. Unprotected according to this standard