Products

IEC 60320-1 Clause 14.2 Figure B.1 Steam Sterilizer Moisture Resistance Test Apparatus

Products Description

IEC 60320-1 Clause 14.2 Figure B.1 Steam Sterilizer Moisture Resistance Test Apparatus

Product information:

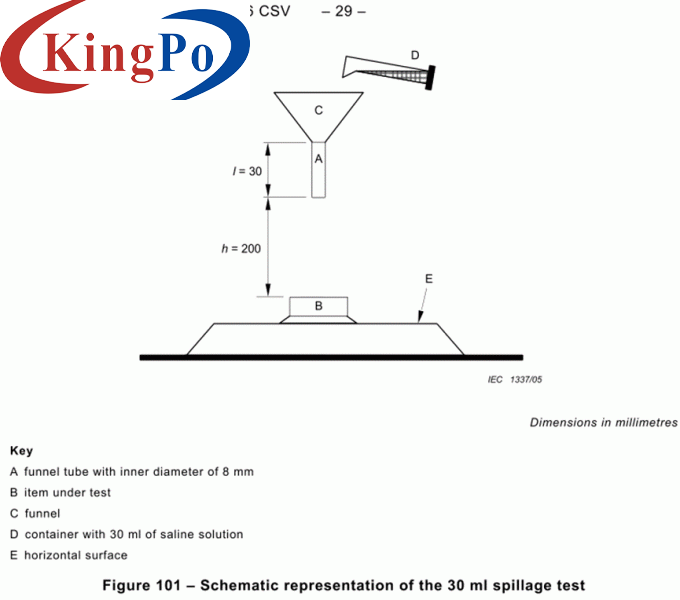

The spillage test apparatus is designed and manufactured according to IEC 60335-2-15 clause 15.2 figure 101, and IEC60320-1 clause 14.2 figure B.1.

It is intended for checking the weight of the protective measures against liquid overflow to ensure that the structure of the plug-in connector (cordless electric kettle) is not affected by liquid when it is installed in an alternative voltage base following the manufacturer’s installation instructions.

Technical parameters:

30ml water containing 1% of NaCl

(The solution should be prepared by user)

1. Sample clamping

According to the standard diagram below, place the sample directly under the funnel, and adjust the height of the funnel tray so that the bottom of the funnel is 200mm away from the sample surface.

2. Test liquid preparation

Prepare 30mL of a solution containing 1% sodium chloride and fill it with a test tube.

3. Connect the electrical strength equipment

Connect the base to the withstand voltage instrument according to the standard.

4. Test operation

Pour the solution in the test tube into the funnel manually within 2s and let it drip onto the sample. Then use the withstand voltage instrument to apply a test voltage of 2500V for the electrical strength test. Determine whether it is qualified according to the standard.

Tube Diameter

8 mm

Tube Length

30 mm

Test Solution Volume

30 ml

Test Solution Type

Distance from the lower end of tube to the appliance

200 mm, adjustable

Apparatus Material

Plastic