Products

IEC 60335-1 Current Carrying Tube Extrusion Resistance Testing Machine For Vacuum Cleaners

Products Description

IEC 60335-1 Current-Carrying Tube Extrusion Resistance Testing Machine For Vacuum Cleaners

Product Overview For Current-Carrying Tube Extrusion Resistance Testing Machine:

Standard: IEC60335-1:2004 "Household and similar electrical appliances-Safety-Part1:General requirements"

IEC60335-2-2:2009 "Household and similar electrical appliances-Safety-Part2-2:Particular requirements for vacuum cleaners and water-suction cleaning appliances,IDT>>clause 21.101"

Samples and Limits: Hoses for Vacuum Cleaners

Technical Parameters For Current-Carrying Tube Extrusion Resistance Testing Machine:

0-99.9s

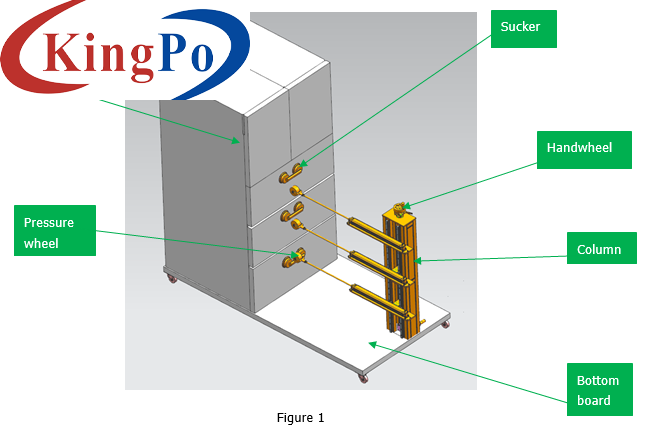

Product Structure For Current-Carrying Tube Extrusion Resistance Testing Machine:

1. Using LCD digital display controller, all parameter settings are processed in the form of dialog box, easy to operate.

2. Display real-time force value, peak value, speed, test times.

13. High performance motor, low noise, small vibration and long service life.

Test purpose: used to assess the performance of the hose of the vacuum cleaner after being squeezed

Test principle: The system controls the motor to drive the sensor to apply the force value, and the pressure plate will automatically return after reaching the preset test force value after pressing the sample.

Input Power

AC220V±10%/50-60Hz

Test station

Single

Control method

PLC control

Force applied method

Electrical

Force applied range

10-2000N, default 1500N

Force accuracy

±0.5%

Test speed

10-250mm/min can be set, default 50mm/min

Test stroke

0-600mm

Test plate

LWH=100×50×20mm, long side rounding R1

one each up and down

Force hold time

Use environment

Working temperature 0-40 ℃ humidity 30%-90%

3. Humanized design, simple operation.

4. Printout: Built-in micro thermal printer.

5. Unit of strength: N, kN, kgf, gf, lbf are selectable.

6. Displacement unit: mm, cm, in are selectable

7. Switchable unit: Pa, kPa, Mpa, kgf / cm2, lbf / in2 are selectable.

8. Protective measures: over-stroke protection, over-strength protection, over-time protection, external limit protection and many other protection methods.

9. High sensitivity, instantaneous determination of crushing and automatic shutdown

10. English visual display

11. Test, rise, fall, return speed can be set by any input, and it can be controlled accurately.

12. The test returns automatically and quickly after the test is completed, avoiding long waiting and speeding up the test efficiency.

14. High-quality S-type alloy steel sensor, high precision, strong resistance to external force and overload.

15. The outer box of the machine is made of A3 steel plate, electrostatic powder spraying and plastic coating.