Products

IEC 60335 Single Station Constant Pressure Water Supply Test Device 2.5MPa

Products Description

IEC 60335 Single Station Constant Pressure Water Supply Test Device 2.5MPa

Product overview:

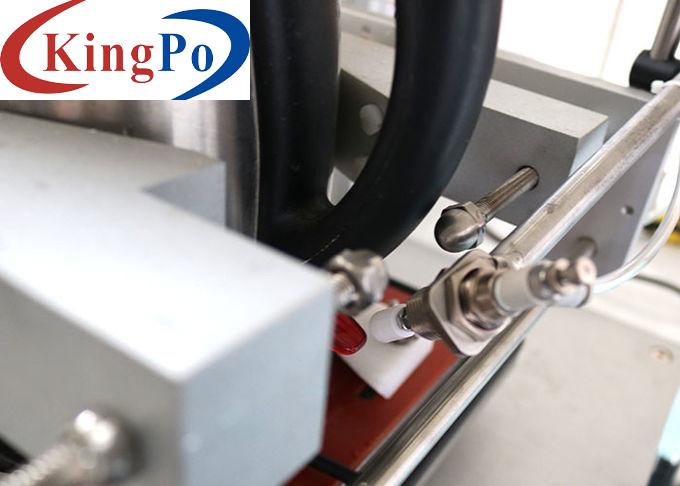

This test apparatus is required by IEC 60335-2-35:2002, IEC 60335-2-21:1997,MOD, IEC 60335-2-7:2008(Ed7.0),MOD,and etc.

It is used for various pressure-bearing products such as valves, water heaters, treated fabrics, etc. to carry out water pressure resistance, static pressure, blasting performance test and water sealing performance test.

Technical Parameters:

Station

Single station

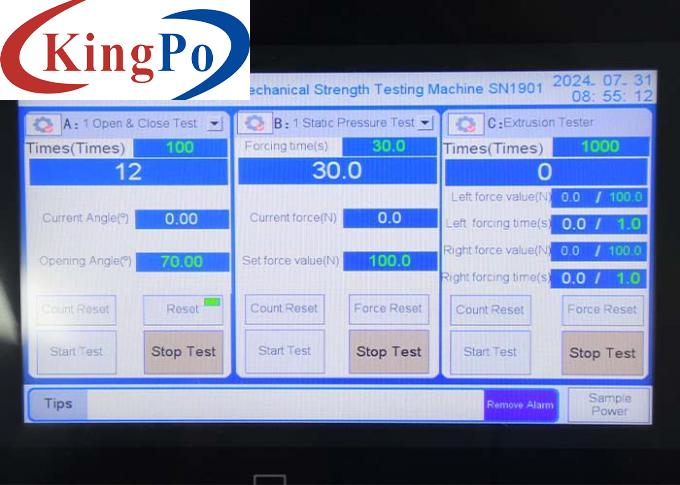

Electrical control mode

PLC control, computer operation

Drive way

Booster pump drive

The test medium

Clean water

Test pressure

0.5-2.5 MPa

Pressure rise rate

0-0.3mpa /s adjustable, default 0.13mpa /s

Pressure holding application

Can be set to 0-999999 - s

Water tank heating function

Optional (0-80°C)

The test process

Manual loading and unloading test, automatic detection process

Equipment size and weight

L*W*H=1870*720*1300, weight about 230KG

Using the environment

Atmospheric pressure 80 ~ 106kpa; Ambient temperature 5 ~ 40°C; Relative humidity (20 ~ 80) %RH; Use place: no violent shaking, vibration, no electromagnetic interference, no dust, no explosive and corrosive gas, good heat dissipation