Products

IEC 60529 Integrated IPX1~6 Waterproof Test System For Testing Electrical Product

Products Description

IEC 60529 Integrated IPX1~6 Waterproof Test System For Testing Electrical Product

Product Overview For Integrated IPX1~6 Waterproof Test System:

The equipment is designed and manufactured according to requirements of IEC 60529 for IPX1 to IPX6 tests. It is used for testing electronic and electrical products, lamps, electric cabinets, electrical components, automobiles, motorcycles and their parts and components’ physical and other related properties under simulated climatic conditions. After the test, it is judged whether the performance of the product meets the requirements, so as to facilitate the design, improvement, verification and factory inspection of the product.

Technical Parameters For Integrated IPX1~6 Waterproof Test System:

Shared system

The total size of the laboratory: 6.5×3.6×4.2m (width*depth*height) (room and drainage tank are prepared by the user)

IP12

Drip area size

2000×2000*60mm (W*D*H)

Maximum sample size

1800*1800*500mm

Distance between drip tank and sample

200 mm (inside)

Drip hole diameter

φ0.4mm

Spray aperture spacing

20 mm

Rainfall

1+0.5mm/Min 3+0.5mm/Min

Turntable

IPX1 turntable is parallel, IPX2 turntable can be tilted 15°

Air source

The buyer should prepare a air source of more than 5kg

Rack material

Coated aluminum alloy profile

IP34

Oscillating tube radius

200, 400, 600, 800, 1000, 1200, 1400, 1600 (mm)

Distance from nozzle to sample

200mm (inside)

Spray aperture spacing

50mm

Spray pipe oscillating angle range

120° 320° (can be set)

Nozzle angle

120°(IP3) 180°(IP4)

Oscillation speed

30°/s oscillating speed: IP3 15 times/min; IP4 5 times/min

Spray hole diameter

φ0.4 (mm)

Flow per spray hole

0.07 L/min +5%

Spray pressure

80-150 (Kpa)

Sprinkler System

IP34: Determine the number of nozzles according to the number of oscillating pipes

Water flow

IP34 The water flow rate is determined by the number of oscillatinging nozzles

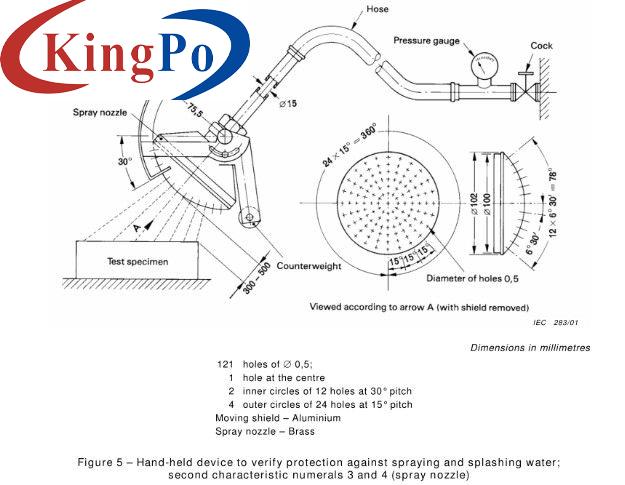

IP56

Number of nozzles

2 pcs; 1 IPX5 nozzle and 1 IPX6 nozzle

Tested surface

The side of the product is the tested surface

Nozzle distance from sample

2500~3000mm, the distance is controlled by the tester

Nozzle inner diameter

IPX5 (grade) φ6.3 mm, IPX6 (grade) φ12.5 mm

Spray flow

IPX5 (grade) 12.5±0.625(L/min), IPX6(grade) 100±5(L/min)

Pipe diameter

One four-point and one-inch high-pressure hose

Spray pressure

30~200kpa (according to flow adjustment)

Spray duration

3, 10, 30, 9999min (adjustable)

Runtime control

1~9999min(adjustable)

Water spray pressure gauge

Water spray pressure can be displayed

Control system

Self-developed touch screen control system

Spray system

Consists of water pump, water pressure gauge, fixed nozzle bracket

Nozzle material

SUS304 stainless steel pipe

Water tank material

SUS304 stainless steel (professional brushed)

Frame material

Coated aluminum alloy profile

Control cabinet material

SUS304 stainless steel (professional brushed)

Turntable speed: 1 ~ 7r/min adjustable

Turntable load: 150 kg

Turntable height adjustable: 300-600mm

Turntable diameter: 200mm, 400mm, 1000mm

Shared water tank

Water tank size: 800×800×1000mm (W*D*H)

Water level: transparent hose, equipped with stainless steel ruler to observe the water level, the height of the ruler is 1.0m, and the accuracy of the ruler is 1mm.

Water tank control: stainless steel float, overflow hole

The box body is reinforced with 304 stainless steel square tube

Mobility: four universal casters to move freely, with brakes

Bottom setting: the water tank is pumped and pressurized by the stainless-steel water pump inside the right control box, and then sent to the nozzle of the side spray pipe device. Nozzles spray water laterally onto the samples above the turntable. Then it is scattered into the water tank to form a water circulation system. Control components such as flowmeters, pressure gauges, and solenoid valves are designed at the pump outlet. The inner box is equipped with a waterproof turntable, and the speed is controlled on the panel.