Products

IEC 60529 IPX6 Water Spray Protection Test System For Vehicle Rain Test With Water Tank

Products Description

IEC 60529 IPX6 Water Spray Protection Test System For Vehicle Rain Test With Water Tank

Product Information:

This rain test room is mainly based on IEC60529:2013 "Degrees of protection provided by enclosure (IP code)" IPX6 and the "Automotive Rain Test Line Requirements" provided by the user, heaviest piece weight and other data compilation, design and production. Used to assess and verify the rainproof performance of vehicle doors and electrical components for high-altitude operations.

Structure:

The system is mainly composed of spray gun mechanism, intelligent control cabinet and water storage tank.

1. The spray gun mechanism consists of a spray gun holder and an IPX6 nozzle with adjustable angle. 4 nozzles are arranged on the spray gun holder. (One on the top, three at a distance of 1 meter, each at 0.5, 1.5, 2.5 and 3.5m). The spray gun holder is equipped with movable roller feet. The spray gun is driven by a servo motor and can spray water up and down, covering all 3.5m test areas in the longitudinal direction.

2. The intelligent control cabinet controls the test water supply, with built-in water pumps, gate valves, solenoid valves, pipelines and flow meters, and the output is connected to the pipeline of the spray gun rack.

3. The water storage tank is configured as a 2-ton water tank, and can also be connected to the customer's existing water source. The water supply needs to be continuously connected during the test.

Technical parameters:

(1) Input power supply: AC380V 50Hz 10kW, and an air-powered switch with leakage protection device is required.

(2) Sample specifications: aerial work vehicle

The size range of the car model is not larger than: 8m long × 2m wide × 3.5m high

(3) Test items: IEC60529:2013 "Degrees of protection provided by enclosure (IP code)" IPX6 water spray test

(4) Spray gun holder: WDH=1050 mm×700mm×3500mm, aluminum profile bracket, stainless steel 304 sealing plate

(5) Nozzle parameters: IPX6: Ф12.5mm, the dimensions are as shown in the standard picture

(6) Water spray flow: 100±5 L/min (each nozzle), adjustable

(7) Water spray distance: The distance between the nozzle and the sample can be adjusted by yourself. The standard requirement is 2.5-3m.

(8) Water spray direction: The motor drives the nozzle to swing up and down to achieve water spray on the top and side surfaces at a height of 3.5 meters. Length direction is achieved by moving the specimen

(9) Spray gun fixing method: fixed on the spray gun holder, 4 of them are arranged (including 1 on the top surface)

(10) Pressure gauge: 0~1MPa, can display

(11) Test time: 0.01S~99.9 minutes, can be preset

(12) Water supply system: stainless steel booster pump water supply

(13) Water storage tank: 2 tons plastic bucket. The test water is supplied from the water storage tank and pumped to the sprinkler system through the sprinkler pump (water supply pump) to spray the sample. The sprinkler water is not recycled and flows out from the concrete ground. The water storage tank is also connected to an external water replenishment mechanism, but when the water level is lower than the requirement, water needs to be continuously replenished. The water storage tank is provided by the supplier.

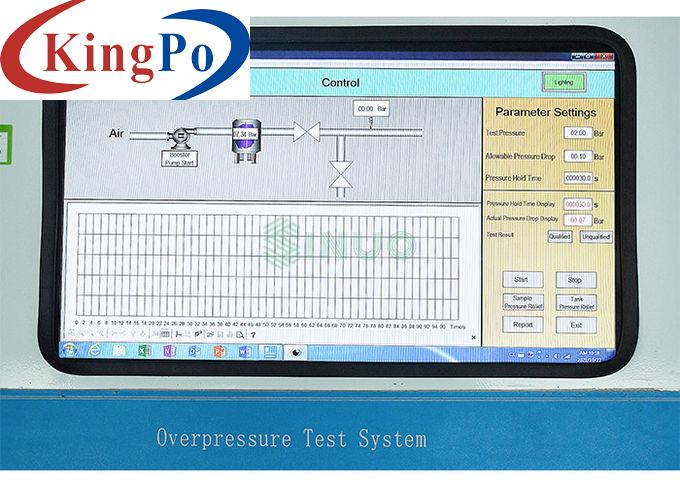

(14) Control: controlled by Mitsubishi PLC, touch screen display and operation, flow meter display. Test time can be viewed via the touch screen interface. The interface is divided into manual and automatic modes.

(15) Safety protection: water shortage alarm, three-color alarm light sound and light prompts when the test is completed