Products

IEC 60598-1 IPX3/4 Spray Nozzle For Water Ingress Protection Of Electrical Enclosures Test

Products Description

IEC 60598-1 IPX3/4 Spray Nozzle For Water Ingress Protection Of Electrical Enclosures Test

Standards compliant:

The IPX3/4 spray nozzle is a specialized testing device used to evaluate the water ingress protection of electrical enclosures, electronic devices, and other equipment against water spray or splashing. It is specifically designed to comply with the Ingress Protection (IP) Code, as defined by the International Electrotechnical Commission (IEC) standard 60529.

The IPX3/4 spray nozzle is used for testing the water resistance of equipment against spraying water from various angles. It can simulate weather conditions where water is sprayed at an angle of 60 degrees (IPX3) or from all directions (IPX4).

Here are some key features and characteristics of the IPX3/4 spray nozzle:

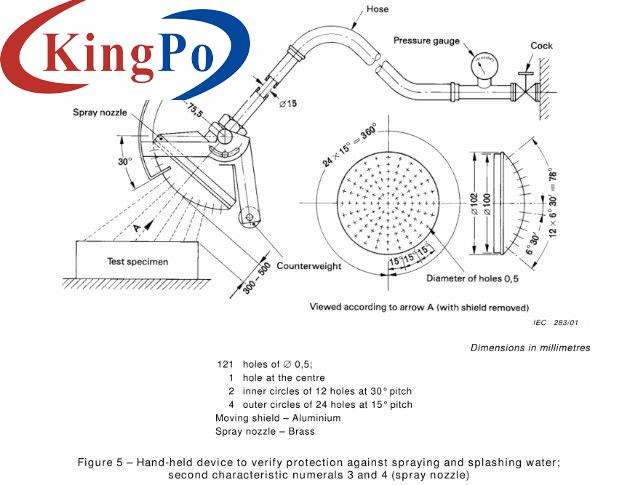

Nozzle Design: The spray nozzle typically consists of a set of nozzles or jets arranged in a specific pattern to generate a controlled water spray. The nozzle design ensures the water is delivered with the appropriate pressure and angle according to the IPX3/4 testing requirements.

Water Flow Control: The nozzle may have a valve or flow control mechanism to adjust the water flow rate, ensuring the specified water volume is delivered during the test.

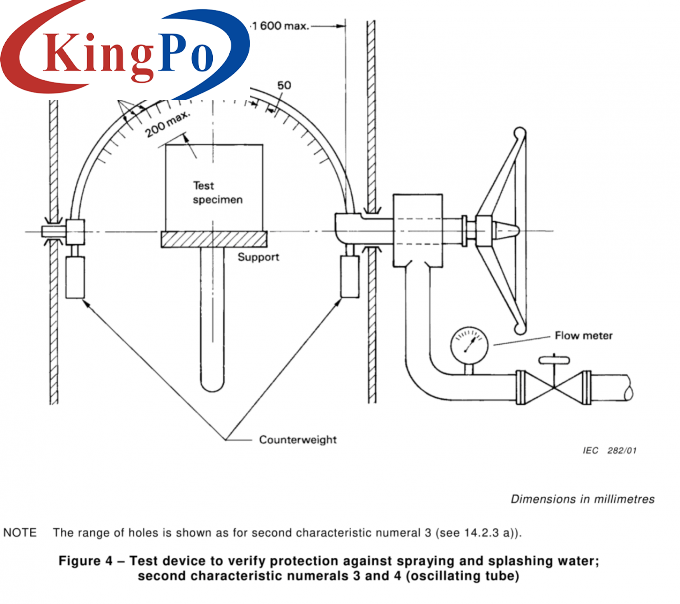

Rotational Function: In the case of IPX4 testing, the spray nozzle may have a rotational function to allow water to be sprayed from all directions. This is achieved by rotating the nozzle or the test sample during the test to cover a 360-degree angle.

Water Supply: The spray nozzle is connected to a water supply system, which can be a controlled water source or a water pump capable of delivering the required flow rate and pressure.

Compliance with Standards: The IPX3/4 spray nozzle is designed to comply with the specific requirements outlined in the IEC 60529 standard for ingress protection testing. Compliance ensures that the testing is conducted according to standardized procedures, providing reliable and comparable results.

During the IPX3/4 testing, the spray nozzle is positioned at a specified distance from the equipment being tested. The water is then sprayed onto the equipment from the defined angles and durations, simulating real-world conditions such as rain showers or splashing water. The test evaluates the equipment's ability to withstand the ingress of water and maintain its protection against water-related hazards.

It's important to note that the IPX3/4 spray nozzle is just one component of the overall testing setup for IPX3 and IPX4 testing. Other equipment, such as a test chamber or enclosure, may be used in conjunction with the spray nozzle to create the necessary testing environment and accurately assess the equipment's water resistance.

Technical parameters:

Made of aluminum, can be detachable

Note: the aluminum moving shield is easy to deform, pay attention during use

Structure:

This device is manufactured according IEC 60529 figure 5, it can achieve IPX3 / IPX4 hand-held spraying test by connecting water pipe.

It eEnsure that the water spraying and splashing speed reaches the standard required value by controlling the water supply flow, make the enclosure of the specimen to be splashed in all directions.

Normally we suggest to adopt the automatic control for IPX3/4 testing, if client has limit budget, the following easy installation for IPX3 and IPX4 testing is for reference:

Parameters of Spray Nozzle

Outer diameter: Ф102mm, spherical diameter: SФ75.5mm, 1 hole at the center, 2 inner circles of 12 holes at 30° pitch,4 outer circles of 24 holes at 15° pitch, total 121 holes of Ф0.5mm, made of brass.

Water Flow

10L/min±5% adjustable by flow meter (flow meter is not included in this item, should be prepared by user)

Pressure

50~150Kpa, the pressure gauge measuring range: 0~0.25Mpa

Moving Shield