Products

- Electrical Appliance Testing Equipment

- Energy Efficiency Lab

- Vehicle Testing Equipment

- Battery Testing Equipment

- Switch Life Tester

- Led Testing Equipment

- Water Ingress Testing Equipment

- Environmental Test Chamber

- Flammability Test Chamber

- EMC Test Equipment

- Medical Device Testing Equipment

- IEC 62368 Test Equipment

- Test Equipment For Electric Lab

Contact us

- No.138 Fuyang Rd,Dalang,Dongguan,523770,China

- +86 076981627526

- weiyunxiao

- sales@kingpo.hk

IEC 60670-1 Mounting Box Tension And Torque Test Device For Enclosures Classified Testing

Price:Customized

StandardPackaging:PlywoodCase

DeliveryPeriod:20Days

PaymentMethod:T/T

SupplyCapacity:10SetsPerMonth

Products Description

IEC 60670-1 Mounting Box Tension And Torque Test Device For Enclosures Classified Testing

Product information:

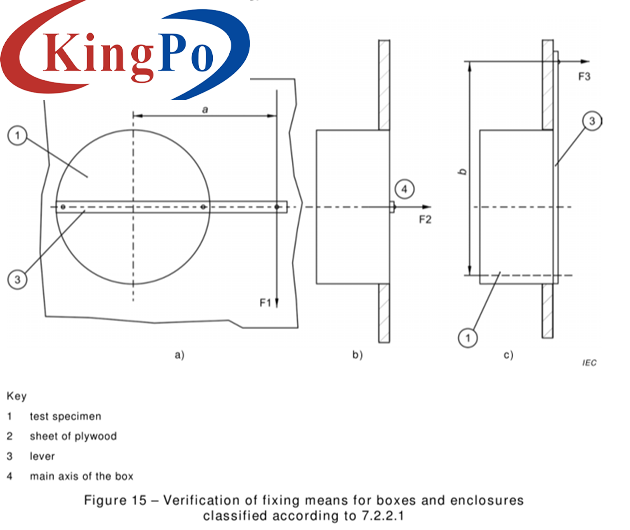

Standard: The device is designed and manufactured according to the standard requirements of IEC60670-1 Clause 12.12, figure 15.

Sample: Concealed and semi-concealed mounting boxes and enclosures classified according to IEC60670-1 Section 7.2.2.1.

Test purpose and principle: For concealed or semi-concealed mounting boxes or enclosures used in cavity walls, the fixing measures cannot be achieved by relying on cable management systems.

This test simulates the normal mounting of concealed or semi-concealed mounting boxes or shells for cavity walls, and conducts the following two tests:

a) Apply F1 tension (to achieve 3N.m torque) according to Figure 15a), and apply F2 tension (100N) to the main axis perpendicular to the mounting plane according to Figure 15b).

b) According to Figure 15c) apply force F3 on the end of the lever for 1 minute (to achieve 3N.m torque) and torque it to the mounting box

After the test, the displacement between the edge of the mounting box and the mounting surface should be less than 1mm.

Equipment Structure and Features:

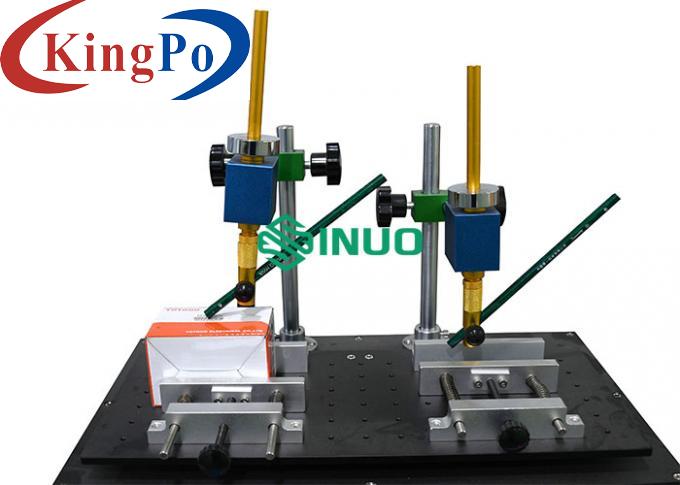

The device consists of a mounting plate, a lever, a fixed pulley mechanism, a weight and a frame.

Equipment dimensions: about: 500×500×1000 (mm) W×D×H, equipment weight: 75kg

Technical parameters:

| Test station | Single |

| Mounting plate | 500*500*10±1mm plywood |

| F1 and a |

F1*a=3N.m

F1=20N

a=150mm (total lever length 220mm)

F3 force direction parallel to the surface of the mounting box

|

| F2 | 100N, slowly applied by lifting and lowering the slide to prevent explosive force |

| F3 and a |

F3*a=3N.m

F3=20N

a=150mm (total lever length 220mm)

F3 force direction is perpendicular to the surface of the mounting box

|