Products

IEC 60695-2-12 Glow Wire Flammability Test Chamber PLC Control

Products Description

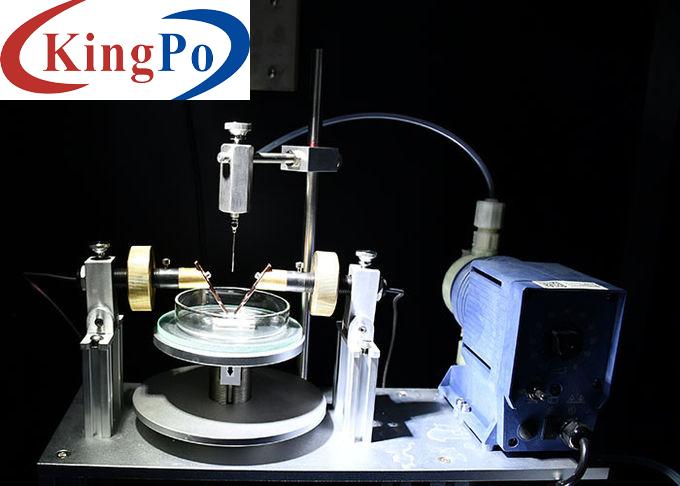

New Version PLC Control Glow Wire Flammability Test Apparatus

Product overview:

This device is manufactured according to the standard of IEC60695-2-10, IEC 60695-2-11, IEC 60695-2-12, IEC60695-2-13, UL746A, IEC 60335, IEC 60598, etc. It also conforms to the standard requirement of UL746A. This device simulates the thermal stress test of glowing component or heat source like overload resistance or ignition source which is caused in s short time. It is suitable for electric and electronic products, household appliances and other material to do fire hazard testing. It is also used in the No flame ignition source fire test to test initiation temperature and flammability index of related glowing filament.

This instrument adopts a new design concept and uses an advanced digital stepping motor to achieve precise positioning, and at the same time, realize rapid adjustment after specimen replacement, which truly meets the requirements of simple and convenient operation. The control system adopts PLC+HMI+stepping motor control, each parameter can reflect the real situation of relevant parameters, which is more real-time and accurately, and the operation is intuitive and convenient, meeting the needs of scientific research, far exceeding similar products.

Technical parameters:

Ф4mm ± 0.04mm Ni/Cr (77/20) special standard

ring shape, horizontal standing

1mm import K thermocouple (Brand: American B+B), the

temperature resistance of armour is 1100 ℃

(better than the standard of 1050 ℃)

500°C-750°C+10%, 750°C-960°C+10%

Temperature fluctuation < 3 ℃

Specimen pressure

on glowing filament

Thickness of ignite

bedding board

Thickness10mm, white pine board cover

12g /m 2 ~ 30g /m 2 standard silk paper

W: 1130mm × D: 600mm × H: 1400mm,

gas vent:100mm, 115KGS

Control & Display

Integrated PLC & 7” color touch screen

Glowing Element

Thermocouple

Temperature Precision

Temperature sensing delay

1.7S

Thermostat

12 bit A/D ±0.05%

0.95N±0.1N (adjustable)

Maximum depth of heating

7mm ± 0.5mm

Specimen movement speed

Approx. 13mm/S

Testing time

30s±0.1s (1s ~ 999.9s can be preset )

Volume of test site

≥ 0.5m³, black background, background illuminance ≤ 20Lx

Dimension and weight

Power

Match client's local power supply requirements

Standard

IEC60695-2-10, IEC 60695-2-11, IEC 60695-2-12, IEC60695-2-13, UL746A, IEC 60335, IEC 60598, etc.