Products

IEC 60702-1 Clause 13.6 Bending Test Apparatus For Mineral Insulated Cables

Products Description

IEC 60702-1 Clause 13.6 Bending Test Apparatus for Mineral Insulated Cables

Product Information:

The Bending Test Apparatus is designed and manufactured according to the standard requirement of IEC 60702-1 clause 13.6, and etc. It is used to test the bending performance of copper core or copper alloy sheathed mineral insulated general wiring cables to verify their reliability.

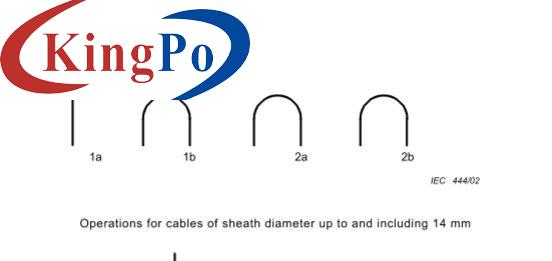

It uses the motor to drive the turntable to rotate. For 500V cables a voltage of 750V and for 750V cables a voltage of 1250V shall be applied, for 15 min in each case, between conductors and between conductors and sheath. For cables having a diameter up to and including 14mm, the sample shall be clamped and bent round the appropriate mandrel so that the cable forms a semi-circle extended by two straight portions (operation 1a). The clamping pressure shall be released and, whilst still in the jig, the sample shall be rotated through 180° around the longitudinal axis of the unbent portion until it is again in the form of a semi-circle extended by two straight portions (operation 1b).

Technical Parameters:

Two independent stations

Small wheel bending station: suitable for a group of 40mm~130mm;

Big wheel bending station: suitable for a group of 160mm~500mm.

Positive direction 180°;

Negative direction 180°

Applied standard

IEC 60702-1

Applied clause

13.6

Power supply

AC380V±10%/50-60Hz, 2.0kW

Drive method

Motor driven

Test station

Test items

Bending direction: positive and negative direction

Sample clamping method

Mechanical clamping, adjustable clamping point position

Bending angle

The specifications of bending wheel(mm)

40, 60, 80, 100, 120, 130, 160, 200, 250, 300, 350, 400,500. Each specification matches 4 PCS.

Bending frequency

More than 1 time/min

Bending times

0~999999, the touch screen can be preset

Equipment dimension

Approx.1400×1000×1300(mm)(W*H*D)

Equipment weight

250KG