Products

IEC 60884-1 2022 Compression Testing Apparatus For VDE Type Plugs Sockets

Products Description

IEC 60884-1: 2022 Compression Testing Apparatus For VDE Type Plugs Sockets

Product Information For Compression Testing Apparatus:

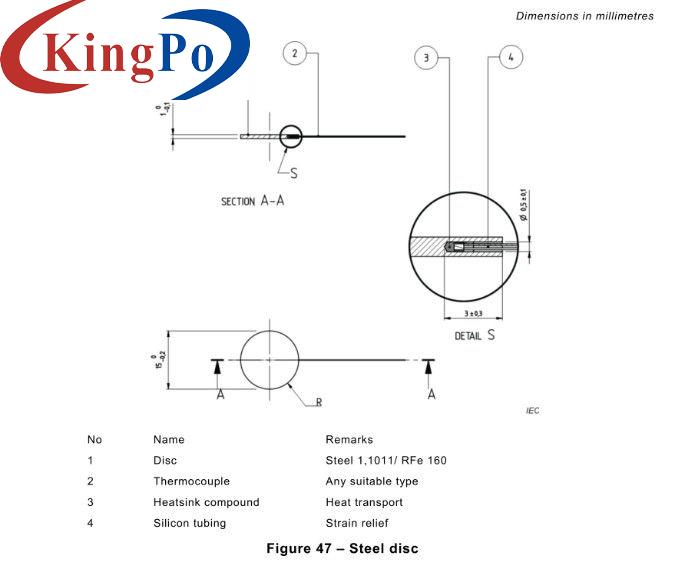

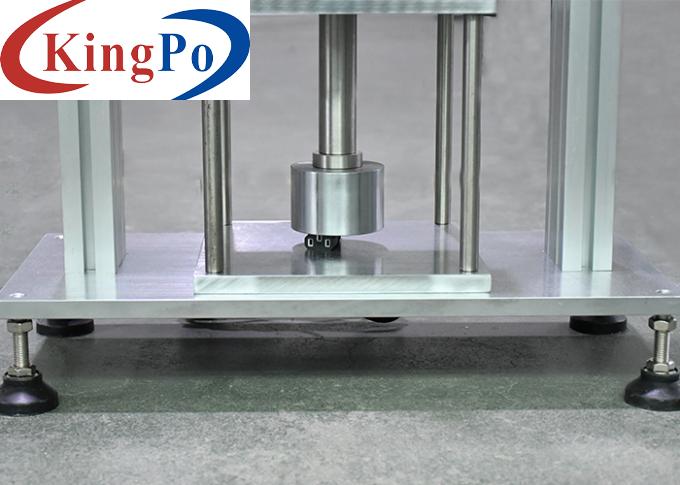

The specimens are subjected to a compression test as shown in figure 8 of IEC 60884- 1:2013, the temperature of the pressure plate, of the base and of the specimens being (23±2) ℃ and the force applied being 300 N.

The specimens are first placed in position a), as shown in figure 8 of IEC 60884-1, and the force is applied for 1 min. They are then placed in position b), as shown in figure 8 of IEC 60884-1, and again subjected to the force for 1 min.

The specimens are removed from the test apparatus and after 15 min they shall show no damage within the meaning of this standard.

Technical Parameters For Compression Testing Apparatus:

Test method For Compression Testing Apparatus:

1. Put the apparatus in a constant temperature environment for testing, and keep the temperature of the pressure plate, base and sample at 23±2℃.

2. Rotate the handle to lift the weight, place the sample directly under the pressing block as shown in Figure a below, rotate the handle to lower the weight, make the sample bear a force of 300N, and start timing for 1min.

3. After 1min, place the sample as shown in Figure b, and bear the force of 300N again for 1min.

4. After the sample is removed from the test device for 15 minutes, the sample should not appear damaged within the standard meaning.

Notice:

1. Please do not damage the appliance shape (such as scratching, bending, etc.).

2. Prevented from dust and moisture environment, in order to avoid the oxidation to affect the dimensional accuracy.

Number of Test Station

1

Operating method

By manual

Weight

150N and 300N (consists of 2 pc of 150N weight)

Conforms to standard

IEC 60884-1 Clause 10.1, Clause 24.5, Fig8