Products

IEC 60884-1 Crimping Terminal Temperature Rise Testing System For Plugs And Socket Testing

Products Description

IEC 60884-1 Crimping Terminal Temperature Rise Testing System For Plugs And Socket Testing

Product information:

Standard: IEC60884-1:2022” Plugs and socket-outlets for household and similar purposes- Part1: General requirements” clause 19.5.1 Temperature rise test for accessories with crimped

Equipment features:

It uses self-programming software and computer-controlled operation. All standard test procedures and data judgments are controlled by the system. It is easy to operate and is used to assess the heating of the plug and socket crimping terminals of the crimping terminals and whether the temperature rise meets the standard requirements.

Technical Parameter:

Maximum output voltage: DC less than DC5V

Output constant adjustable test current: DC0~100A

Current display accuracy: ±(0.25% reading + 0.25% range), resolution 1A

Voltage display accuracy: ±(0.25% reading + 0.25% range), resolution 0.01V

Test current stability: ±(1% set value + 0.5A), response time about 1S

2. Control contact power supply: current range AC (0~2) A;

3. Working mode: continuous mode, on-off mode, automatic temperature control mode

Continuous on-off mode:

Continuous mode test time: 0.01~99.99 hours

On/off mode power on/off time: 0.01~99.99 hours

Number of on-off times: 1~9999 times, automatic shutdown when the number reaches

Current setting: Program-controlled setting, which can realize qualification judgment according to standards:

a) The measured temperature rise of each crimped connection shall not exceed 45 K.

b) The average of 6 temperature rise measurements of the pressure connection recorded during the 250th cycle shall not exceed 35 K.

(c) Calculate a linear trend line for all six measurements and draw the trend line through the measurement points from the 50th to the 250th cycle. At the 250th cycle, the value given by each trendline should not exceed the value given by the trendline at the 50th cycle by more than 5K.

When c) is not met, the test shall be extended to 500 cycles and the following compliance conditions shall be attached.

d) The average of the six temperature rise measurements of the pressure connection recorded during the 500th cycle shall not exceed 35K.

(e) A linear trend line shall be calculated for all six measurements and drawn through the measurement points from the 250th to the 500th period. At the 500th cycle, the value given by each trend line shall not exceed the value given by the trend line at the 250th cycle by more than 10 K.

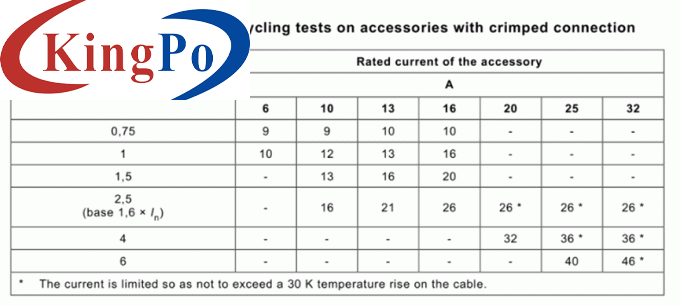

The current can be selected according to IEC60884-1:2022, as shown in the following table

Automatic temperature control mode: You can set a stable temperature rise value and automatically find the appropriate current value.

Temperature rise setting range: 0~100℃

Stable accuracy ±0.5℃

Automatically obtain the current result of the required temperature rise value

4. Temperature rise test (built-in temperature detector):

Temperature measurement range: 0~260℃ Accuracy ±0.3% of reading +1℃; Resolution: 0.1℃

Temperature measurement points: 16 channels (including 1 channel to measure ambient temperature);

Thermocouple: The instrument supports J, K, T, E, S, N, B, R and other types of thermocouples.

Temperature measuring thermocouple: K-type 30AWG filament thermocouple from the American Ω Company, 2 meters long, 20 in total;

The temperature probe can be tested with electricity without damaging the instrument.

Temperature scanning speed, record storage interval: 0.1 ~ 1800 seconds for all channels

Temperature data recording: automatically completed by computer, configured with computer testing software

The software can set the ambient temperature channel, and the ambient temperature can be automatically subtracted when collecting data.

5. Voltage drop, resistance test function: The equipment is equipped with a mV meter, which can detect the voltage drop at both ends of the connector and calculate the resistance value.

6. Equipped with a touch screen integrated industrial computer (Pentium 4/1.8G or above CPU, 4G memory, 64G solid state drive, 15-inch LCD monitor), installed with XP Chinese operating system and OFFICE processing software

A. Power setting mode: It has programmable editing settings, can set no less than 10 segments of current programs, can continuously implement different current values, has clock switch function, operation interface setting, automatic adjustment, and automatic reset;

B. Multiple working mode options: continuous mode, on-off mode, automatic temperature control mode

C. Data display: can display the temperature value of each channel, current value, and time axis curve in real time, sampling frequency: 100ms~1800s adjustable, data recording interval: 100ms~1800s adjustable;

D. Data preservation: with automatic or manual test data preservation function, storage space at least 8G;

E. Data export: with USB data export function, data can be exported to CSV, XLSX and other format files;

F. Power setting method: with programmable editing settings, can set no less than 10 current output programs, can continuously implement different current values, with clock switch function, operation interface setting, automatic adjustment, automatic reset;

7. Power supply: AC220V±10%, 50/60Hz, 2KVA

8. Dimensions: about 800mm wide × 1000mm deep × 1600mm high, weighing about 200kg

Equipped with heavy-duty brakeable mobile casters for easy fixing and moving

9. Equipped with overload protection and overcurrent protection functions

When the equipment stops, the current output is automatically cut off.

The equipment can work continuously for a long time and is stable and reliable

10. Temperature rise test fixture configuration: 800*600*400mm, acrylic transparent windproof cover, built-in 20mm thick vertical wooden board, the distance between each test sample is not less than 150mm, the new equipment must provide enough for 12 (3 rows* 4 columns) test table with samples installed simultaneously. And in order to prevent the influence of the air flow of the air conditioner in the laboratory.

24 pcs (12 pairs) Figure 20 clamping unit Temperature rise test fixture (customized according to plug pin standards).

10. Equipment overview (the picture includes the computer):