Products

IEC 60884-1 Flexible Cable Cord Anchorage Torque Test Device For Plug And Sockets Test

Products Description

IEC 60884-1 Flexible Cable Cord Anchorage Torque Test Device For Plug And Sockets Test

System overview

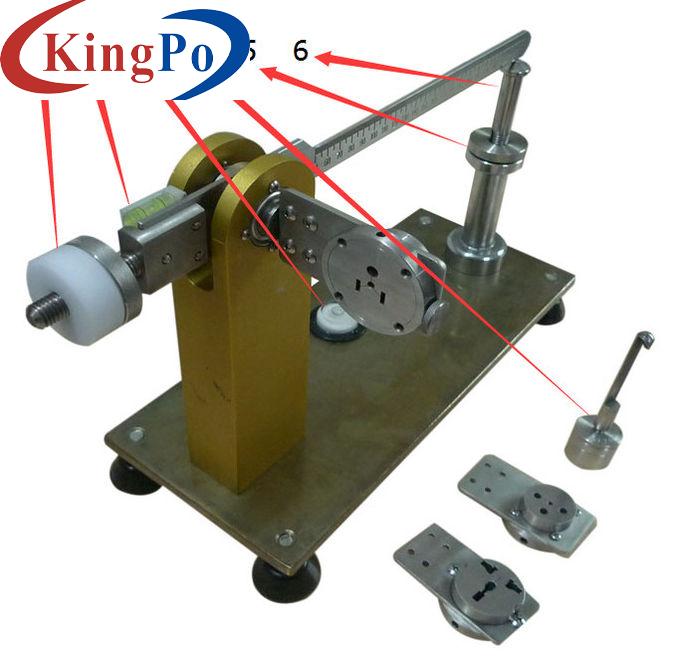

Complies with IEC60335-1 clause 25.15, IEC 60884-1:2006 clause 23.2 and table 18, VDE0620 clause 23.2 and table18, etc.

It is used to check wear resistance of plug, mobile socket mobile sockets, fixed parts fitted with conductors and their connectors under sheath protection without stress, including twisting, at the end of the conductor. Using weights to apply force to the specimen with a certain force arm to meet the standard torque value.

Structure

Using weights to apply force to the specimen with a certain force arm to meet the standard torque value.

Outer size:about:300×200×300(mm)W×D×H,equipment weight:10kg

Working temperature:0-40℃, humidity:30%-90%

Technical Parameters

One weight for each of 2N, 3N, 5N, 7N and 8.5N

One set of tools.

One set of big sample fixed screws

Operation Steps

1. Instrument horizontal adjustment:

When the instrument is used for the first time, it needs to be adjusted horizontally. First, place the instrument on a horizontal platform and adjust the four legs of the instrument so that the horizontal bubble is in the center.

2. Adjustment of the fixture position

The fixture of this equipment has a horizontal width of 60 mm and a vertical width of 60 mm. You can loosen the positioning screws first, determine the fixture position, and then tighten the screws.

3. Installation of the sample:

Adjust the four plastic screws on the fixture and fix the sample on the fixture so that the sample cord is on the center line.

4. Start the test

After the sample is correctly installed, it is necessary to hang an appropriate weight and apply a torque to the sample for 1 minute. The test results are judged according to the wear of the cable sheath.

Note: This test should be carried out after the cable retention test is completed.

Torque Disc Diameter

100mm

Torque Calculation

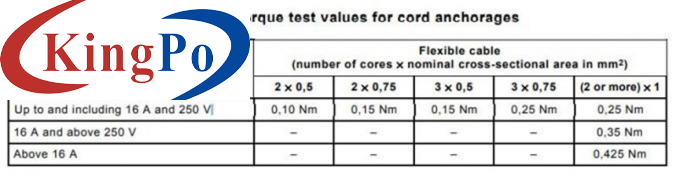

G.L unit N.m,can achieve 0.1,0.15,0.25,0.35,0.425N.m torque

Apply Force Time

0-9999times, adjustable, default 100times

Load Weights

2N*1,3N*1,5N*1,7N*1,8.5N*1

Torque test value for cord anchorages

Fixture opening

Horizontal width 60 mm, and the vertical width 60 mm

Accessories