Products

IEC 60884-1 Screwless Terminals Deflection Test Apparatus 100A

Products Description

IEC 60884-1 Screwless Terminals Deflection Test Apparatus

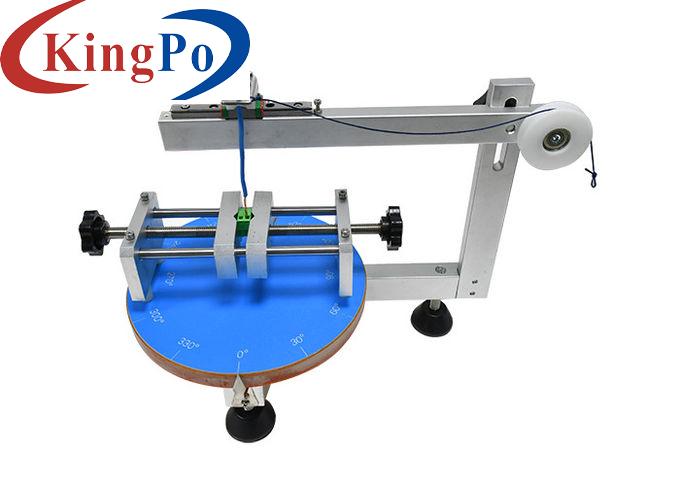

This device complies with IEC 60884-1:2013 clause 12.3.12 and figure 12, it is used to use to check whether the screwless terminals connected rigid solid conductor remains clamped, even when it has been deflected during normal installation. Deflecting the conductor and measuring the voltage drop, to check the screwless terminal clamping capacity and contacting performance.

The device is easy for operating, the load current is adjustable, the sample fixture is manufactured according to the standard requirements.

Technical Parameters:

0-360°

(there is an angle indicator in the device)

In any of the 12 directions differing from each other by 30°±3°

(manually deflected)

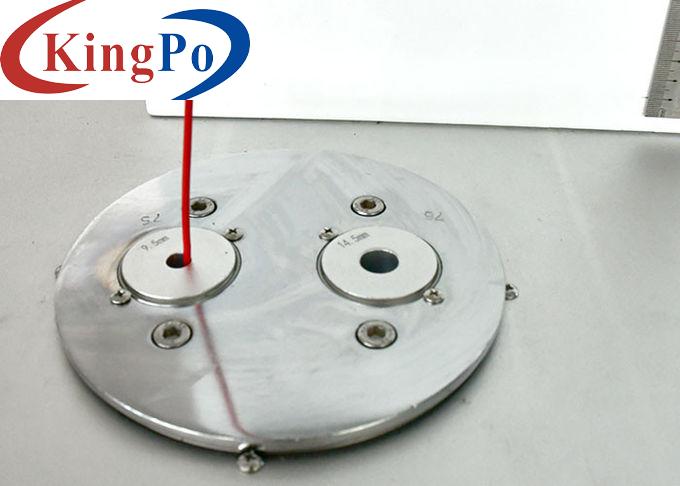

2. Placed the screwless terminals into the fixture, the perpendicular of the conductor should be coincided with the center of the base. The upper conductor passes through the holes of the force plate, the lower conductor should not touch the floor , then clamp the terminal parts.

4. The red clip of the current output of the voltage drop tester is clamped on the upper conductor, and the red clip of the voltage drop measurement input is clamped in the position near the terminal, then hang on the weight.

5. clamped on the lower conductor, and the black clip of the voltage drop measurement input is clamped in the position near the terminal.

6. Rotate the base turntable, each rotation is 30 °, the starting point should be where the conductor in a natural state.

Parameters Name

Parameter Data

Deflection angle

Deflection direction

Deflection force

0.25N, 0.5N, 1.0N

Force applied direction

Perpendicular to the undeflected conductor

Test current

Max.100A

Accessories

Voltage input clamps and current output clamps

Power supply

Match client's local power supply requirements

3. Loose the fastening handle of the support column and move the crossbar up and down, so that the distance from the end of the terminal to the force plate is 100 mm. The crossbar must be kept horizontal.