Products

IEC 60950 Clause 2.10.8.4 Harden Steel Pin Scratch Resistance Test Apparatus

Products Description

IEC 60950 Clause 2.10.8.4 Harden Steel Pin Scratch Resistance Test Apparatus

Equipment Overview

1 Standard compliant

The device is used to check abrasion strength of printed circuit boards or the insulating accessible parts of the household appliances. It conforms to the standard requirement of IEC 60335-1 clause 21.2, IEC 60950 clause 2.10.8.4, etc.

2 Working principle

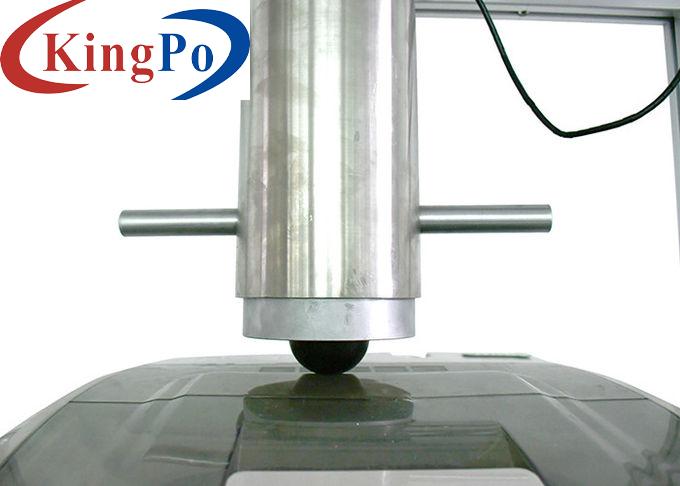

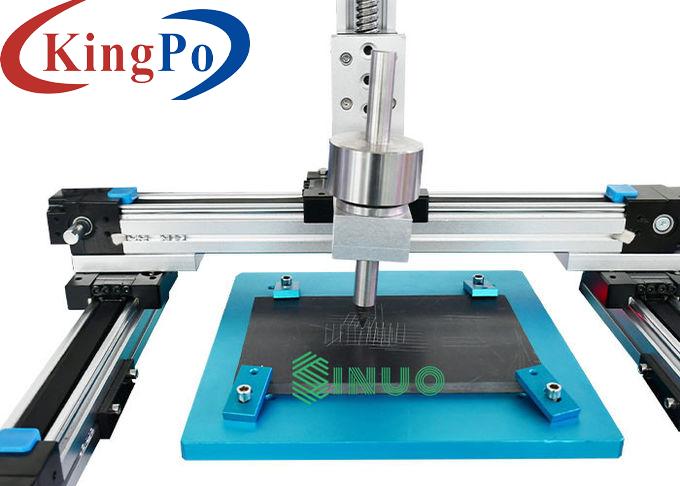

The surface of the insulation is then scratched by means of a hardened steel pin, the end of which has the form of a cone with an angle of 40o. Its tip is rounded with a radius of 0,25 mm ± 0,02 mm. The pin is held at an angle of 80o to 85o to the horizontal and loaded so that the force exerted along its axis is 10 N ± 0,5 N. The scratches are made by drawing the pin along the surface of the insulation at a speed of approximately 20 mm/s. Two parallel scratches are made. They are spaced sufficiently apart so that they are not affected by each other, their length covering approximately 25 % of the length of the insulation. Two similar scratches are made at 90o to the first pair without crossing them.

3 Equipment characteristics

This tester adopts PLC + touch screen control system and stepper motor drive, the scratch distance, scratch times and scratch speed can be preset on the touch screen. And it with a 90o auto-rotation test bench, so it is easy to realize the scratching test in both vertical and horizontal direction.

Technical parameters:

Test steps

After setting the parameters, press the "Homing" button to make hardened steel pin back to the initial point, then press "Start" button to begin test. Test procedure: hardened steel pin runs to the starting position-- hardened steel pin runs downward to touch the surface of the test sample -- hardened steel pin runs rightward to scratch the test sample-- hardened steel pin runs back to highest point-- hardened steel pin returns to starting point-- hardened steel pin runs forward one scratch spacing-- hardened steel pin processes the next scratch, when reaches to the preset test times, the test system will automatic shutdown and hardened steel pin return to the initial point.

Input power supply

AC 220V/50Hz

Test station

One station

Control system

PLC + touch screen

Drive mode

Stepper motor drive

Scratching speed

0-25mm/s adjustable, can be preset

Scratching times

0-9999 times, it can be preset

Scratching distance

Approximately 25 % of the length of the insulation, can be preset

Test bench

Can be 90o rotated

Scratching pressure

10N±0.5N, it can be equipped with the weight of 20N to reach the scratching pressure of 30N±0.5N

Scratching pin

hardened steel pin, the end of which has the form of a cone with an angle of 40o. Its tip is rounded with a radius of 0,25 mm ± 0,02 mm

Scratching angle

80o to 85o to the horizontal