Products

IEC 61591 Air Performance Test System For Cooking Fume Extractors

Products Description

IEC 61591 Air Performance Test System for Cooking Fume Extractors

Technical parameters:

1. Laboratory power supply: AC 220V/AC 380V 50HZ; capacity: 5KVA

2. Laboratory environment: 20℃±5℃ Humidity: 30%--80% Atmospheric pressure: normal

3. Measuring wind volume range: (0.06-25 cubic meters)/min, (3.6-1500 cubic meters/hour)

4. Static differential pressure: 0—1500 Pa ±0.2%

5. Electrical parameters: AC and DC are common, the measurement accuracy of voltage, current and power is 0.2, digital display instrument Range: voltage AC 0-300V current AC 0--10A power 0-1000W

6. Speed: 0-5000 rpm ±5RPM digital display

7. Air temperature: 0—50℃ ±0.5℃

8. Air humidity: (5~99)%R﹒ H ±5%

9. Variable frequency regulated power supply: customer-provided

10. The measurement results that can be automatically calculated by the computer after the test is completed;

1) Maximum static pressure (static pressure value at zero wind volume): Ps2n (max) Pa

2) Maximum wind volume (wind volume value at zero static pressure): Qv (max) m3 /min

3) Static pressure at specified wind volume (7m3/min): Ps2ns Pa

4) The input power of the main motor when the wind volume is specified (7m3/min): P W

5) Full pressure efficiency at specified wind volume (7m3/min): η %

6) The wind volume and pressure corresponding to the working wind volume point (according to GB/T17713-20XX)

7) Maximum full pressure efficiency (according to GB/T17713-20XX)

8) Fluid dynamic efficiency (FDE hood): η % (including the corresponding optimal wind volume, static pressure, power)

9) Energy efficiency (EEI hood): η % (including the corresponding lighting system power label)

10) Pressure and wind volume corresponding to 5Pa, 10Pa, 15Pa characteristic curves

11. It can map the corresponding curves of static pressure and wind volume, wind volume and speed, current, power, efficiency, etc. Samples can also be tested in both inhalation and expulsion states.

12. Test mode: The machine has two test modes, automatic test and manual test mode

1) There are two test methods for automatic test, as follows:

2) In the manual test part, there are four test methods, as follows:

13. Summary of the test range of each parameter

System introduction:

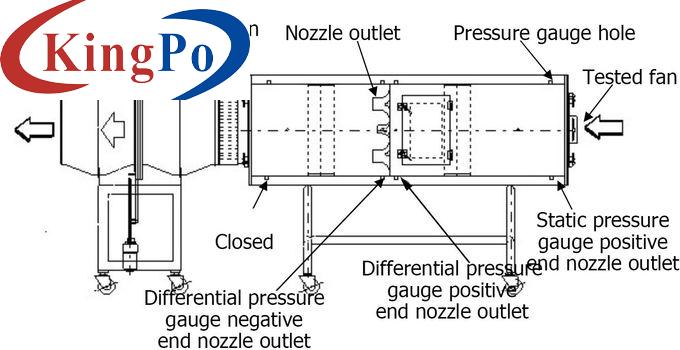

The F-401-025 wind volume measurement test device is a wind volume measurement system developed and manufactured according to the ISO5801, IEC61591 and etc. standards and using advanced Japanese technology.

The basic test principle is: simulate the actual working state of the sample in the test wind tunnel (the auxiliary fan makes the wind outlet pressure of the sample consistent with the requirements), and then measure the wind pressure difference on both sides of the nozzle in the wind tunnel, and then use the standard formula calculates the corresponding wind speed at this time, and finally multiplies the nozzle area and the relevant flow coefficient to obtain the wind volume.

The device adopts computer automatic measurement and control method. It only needs to manually install the sample and replace the nozzle. The whole process of testing a sample only takes ten minutes. It can map the corresponding curves of static pressure and wind volume, wind volume and speed, current, power, efficiency, etc. The test can also be tested in two states of inhalation and expulsion. It has the characteristics of convenience, speed, stability and reliability, and good reproducibility. Meet the test and use of related products in the scientific research and production process.

Application: Range hoods, ventilation fans, Yuba, heaters, cooling fans, axial fans, air purifiers, etc.

Performance and feature requirements:

1) The device adopts a multi-nozzle wind chamber structure. The corresponding nozzle can be selected according to the measured flow, so one device can measure a wide range of wind flow.

2) It can be used for both inhalation and expulsion testing.

3) Auxiliary fans are equipped, so the full-range performance curve with zero flow and zero static pressure can be measured.

4) Automatic test, calculation and data output are realized by the computer and its peripheral equipment, and the test results are printed and displayed graphically. The man-machine dialogue is easy to operate, with high precision, saving time and effort.

5) Test items: P-Q characteristic (relationship between flow rate and static pressure), drawing smoke exhaust resistance curve, Q-η characteristic 1 (relationship between flow rate and total pressure efficiency), flow resistance efficiency, Q-η characteristic 2 (relationship between flow rate and flow resistance efficiency), Q-η characteristic 3 (relationship between flow rate and energy consumption efficiency), flow resistance test items, and simultaneous measurement of the rotational speed, current, and power of the measured object.

The following new features have been added to the device:

Overall Scheme:

(This scheme does not include the structural part of the laboratory building, which is built by the user according to the standard requirements)

1. General requirements of the laboratory

Size: 4500 (width) × 6000 (length) × 2800 (height) mm or more.

Walls: smooth and flat, with no openings that affect wind flow (air conditioner openings should not blow directly).

Ground: The ground should be kept flat.

Temperature and humidity: When measuring the wind volume, the air temperature of the test room is 20℃±5℃, and the humidity is 30%-80% (user-provided air conditioner or dehumidifier).

Atmospheric pressure: Normal atmospheric conditions not exceeding 1000 meters above sea level.

2. Test System

Main components: wind volume test wind tunnel, auxiliary fan and damper adjustment mechanism, measurement and control electrical cabinet (including variable frequency power supply, electrical parameter measuring instrument, pressure transmitter, tachometer, etc.), brand computer, printer, sample lifting platform, sample installation method blue and test duct.

System function: After the computer prompts the input of sample parameters and test-related data, all automatic measurement and control functions can be realized: including, wind volume measurement; voltage, current, power measurement; rotational speed measurement, temperature, humidity and atmospheric pressure measurement, test process prompts, data tables, correlation curves, etc.

3. Power distribution requirements

Users need to provide independent power distribution switches, three-phase four-wire plus ground wire power supply: AC 380V, 50Hz. Maximum capacity: 5KVA

A. Inhalation test

B. Expulsion test

Project

Unit

Range

Accuracy

Wind volume

M³/min

0.06-25

±1% of the maximum wind volume of each nozzle

Static pressure/differential pressure

Pa

0-1500

±0.2%

Rotating speed

Rpm

0-5000

±5rpm

Current

A

0-10

±0.2%

Voltage

V

0-300

±0.2%

Power

W

0-2000

±0.2%

Temperature

℃

0-50

±0.5%

Humidity

%

5-99

±5%

Air pressure

Pa

90000-106000

±200pa