Products

IEC 62196-1 2022 Label Marking Abrasion Test Apparatus Verify The Durability Of Marking

Products Description

IEC 62196-1: 2022 Label Marking Abrasion Test Apparatus Verify The Durability Of Marking

Product information:

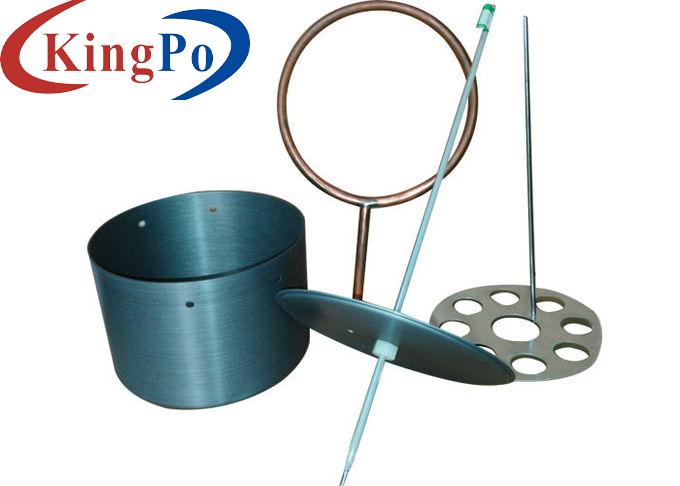

This label marking abrasion test apparatus conforms to IEC 62196-1:2022 clause 8.7, figure 8. It is used to verify the durability of marking.

The test is made by rubbing the marking for 15 s with a piece of cotton cloth soaked with water and again for 15 s with a piece of cotton cloth soaked with n-hexane 95 % (Chemical Abstracts Service Registry Number, CAS RN, 110-54-3).

The marking surface to be tested shall be dried after the test with water.

Rubbing shall commence immediately after soaking the piece of cotton, applying compression force of (5 ± 1) N at a rate of about one cycle per second (a cycle comprising forward and backward movement along the length of the marking). For markings longer than 20 mm, Rubbing can be limited to a part of the marking, over a path of at least 20 mm length.

The compression force is applied by means of a test piston which is wrapped with cotton comprising cotton wool covered by a piece of cotton medical gauze.

The test piston shall have the dimensions specified in Figure 8 and shall be made of an elastic material which is inert against the test liquids and has a Shore-A hardness of 47 ± 5 (for example synthetic rubber).

Technical parameters:

Maintenance Notes:

1 The instrument must be placed on a stable surface before use.

2 It is not allowed to move the machine during use.

3 Select the appropriate power supply voltage, should not be too high, to avoid burning the instrument.

4 If the instrument works abnormal, please contact with us for timely processing.

5 The instrument must be used in a good ventilation environment.

6 Please add lubricating oil to the mechanical transmission part in time due to the large operating load of each component of the button mechanism.

7 After each test is completed, operator should clean the machine.

8 The control box part must be wiped with a dry cloth.

Test station

2 stations

Electrical control method

Button control

Drive mode

Electric

Sample clamping method

Mechanical clamping, clamping point position is adjustable

Test Cycle

0-9999 cycles, can be preset

Test speed

One cycle/s (a cycle comprising forward and backward movement along the length of the marking)

Force

5±1N,applied by a weight

Test piston

NF C 61-314 figure 48,rayon, Shore-A hardness shore A 47± 5