Products

IEC 62196-1 Electric Vehicle Non - Rewireable Strength Flexing Test Equipment

Products Description

Electric Vehicle Non-rewireable Mechanical Strength Flexing Testing Apparatus

Product information:

The test equipment is used to process the mechanical load flexing test of the vehicle plugs, socket-outlets and couplers non-rewireable accessories.

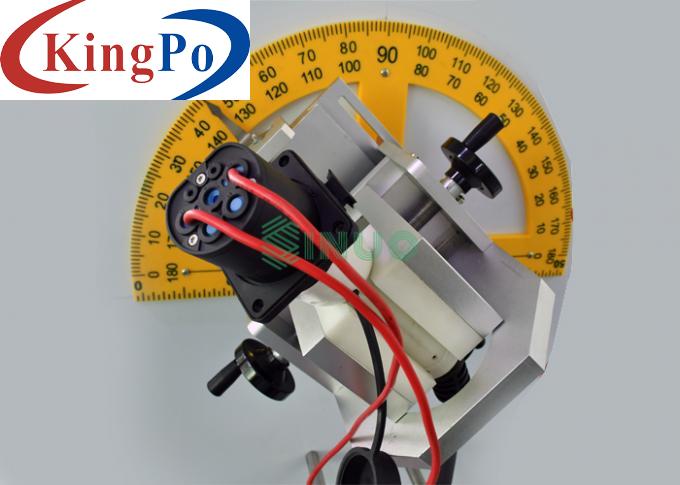

Adopts the servo motor to drive the turntable, to make the specimen to swing left and right, the test will be automatically stopped when the test cycles reach the preset value.

Applied standard & clauses:

IEC 62196-1Ed.4CDV 2020 clause 26.4, fig 20, table 14.

Structure:

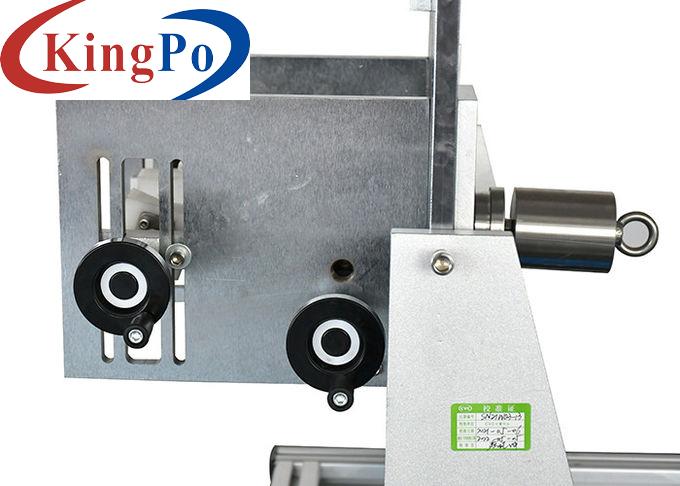

The device is driven by a servo motor, with mounting aluminum plate for large size samples, it can realize that the oscillation axis matches the cord entering point as much as possible when clamping the sample, thereby achieving a minimum lateral displacement of the flexible cable and load.

Technical parameters:

Test Station

Single

Electrical Control Method

PLC intelligent integrated control, 7-inch humanized touch interface operation

Drive Mode

Servo motor

Sample Clamping Method

Mechanical clamping, the position of clamping point is adjustable

Flexing Angle

0-360° can be adjusted freely (default 90°, 45°on either side of the vertical)

Flexing Rate

0-60 cycles / min, can be preset

Flexing Cycles

0~999999 can be preset, default 20000 cycles

Load Weights

20N, 25N, 50N, 75N, 100N, 120N, 140N, 180N

Load Power

External (not included), load cabinet with adjustable voltage between conductors 0-250V and current AC0-800A adjustable is optional

Test Judgment

Judging by the signals given when the current is conducting or not

Equipment Dimensions & Weight

W950*D650*H1600mm, the whole machine is about 320Kg

Power Supply

Single phase AC220V±10%, 60Hz, 10A