Products

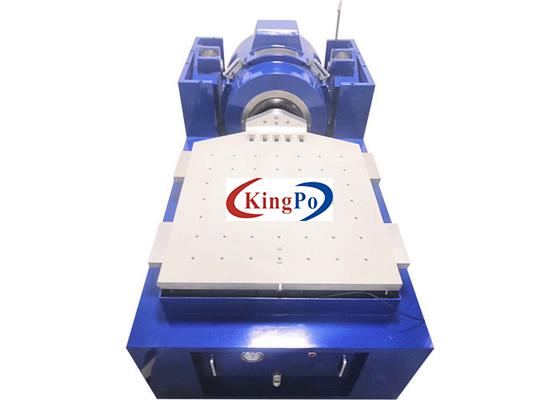

IEC 62368-1 Annex G.15 High Stability Performance Vibration Test System

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Standard Exporting Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 15 Sets Per Month |

Products Description

IEC 62368-1 Annex G.15 High Stability Performance Vibration Test System

Product overview:

This vibration system is required by IEC 62368-1:2018 Annex G.15, IEC60065:2014 clause 8.17 b), 12.1.3, IEC60950 and etc.

The vibration test system consists of four parts: vibration test bench, power amplifier, controller and cooling fan.

1. Vibration test bench

The working principle of the vibrating table:

The energizing conductor is driven by the electromagnetic force in the magnetic field. When the dynamic circle in the magnetic circuit of the electromagnetic vibrating bench passes the alternating current signal, an exciting force is generated in the magnetic circuit.

Dynamic circle:

The most important part of the electric vibration table is the dynamic circle, the dynamic circle is an active system. It drives the coil which is placed in the working air gap generated by the magnetic circuit system, to achieve free up and down vibrations by energizing the drive coil.

Excitation coil:

The excitation coil of the electric vibrating table is divided into upper excitation and lower excitation. The two together with the dynamic coil form two mutually perpendicular magnetic fields. The coils are cut to each other to generate magnetic induction force when energized, in this way, the vibration bench generates the required exciting force by cutting between the dynamic coil and the excitation.

2. Power amplifier

The working principle of the power amplifier: the three-phase AC power is isolated by the power frequency transformer, the buck is sent to the three-phase full-bridge filter, and then the low-ripple DC power supply is sent to the H-bridge transformer through the capacitor filtering, and the output voltage wave passes the normal mode and the common mode choke coil, and is filtered and output to the vibrating table.

3. Control part

Our controller uses the world's most advanced DSP framework and control algorithm, 32-bit floating-point 450MHz DSP processor, high-performance 24-bit ADC, up to 130dB dynamic range, ensuring reliable control quality. At the same time, the controller can provide you with the most comprehensive vibration control software module, including: random, sinusoidal, classic shock, resonance search and dwell, shock response spectrum control, sine plus random, sine plus sine, random plus random, long-term waveform Reproduction and other accessibility features. Each function module provides basic and optional functions, and the user can customize the required functions as needed.

4.Vertical Expansion Countertop

Technical Parameters:

Applied Standard

IEC 62368-1

Applied Clause

G.15

Vibration generator (DC-2000)

Sine Force

2000kgf (20000N)

Random Force

2000kgf (20000N)

Impact Force

4000kgf (40000N)

Frequency Range

5~3000Hz

Continuous Displacement (Amplitude)

0-51mm, preset

Vibration Isolation Frequency

2.5Hz

Level One Resonant Frequency

2600±5%Hz

Countertop Screw

17*M10

Magnetic Flux Leakage

<1MT

Maximum Speed

2m/s

Maximum Acceleration

980m/s2 (100g)

Equivalent Mass of Moving Parts

20kg

Dynamic Coil Diameter

Φ280mm

Max. Loading

300Kg

Weight

2695kg

Switching Power Amplifier (KA-21)

Amplifier Output

21KVA

Rated Output Voltage

120Vrms

Signal to Noise Ratio

>65dB

Power Amplifier Efficiency

>95%

System Protection

Temperature protection, over-displacement protection, over-voltage protection, over-current protection, under-voltage protection, external protection, logic fault protection

Dimensions

1800*900*800mm

Weight

450kg

Vertical Expansion Countertop(TB-1010)

Table Size

1000mm×1000mm

Table Weight

60kg

Highest frequency

200Hz

Level Table (S-1010) Optional

Table Size

1000mm×1000mm

Table Weight

60kg

Highest frequency

200Hz

Computer and Related Accessories

Host

Lenovo

Monitor

Customized according to the reserved position of the electric chamber

Fan(FJ-2000)

Fan Power

7.5KW

Air volume

0.71M3/s

Wind Pressure

3.5Kpa

Dimensions

500*300*200mm

Duct length

4m

Weight

140kg

Accelerometer(JF)

Sensitivity

150pc/g

Frequency Range

0.3-8000Hz±10%

Measuring Range

2000g

Impact Resistance

2500g

Line length

5m

Operating Temperature

-40-150℃

Weight

35Gram

Installation Method

M5