Products

IEC60086-4 Lithium Ion Battery and Cell Safety 1000A External Short Circuit Testing Equipment

Products Description

IEC 60086-4 Lithium Ion Battery and Cell Safety 1000A External Short Circuit Testing Equipment

Overview:

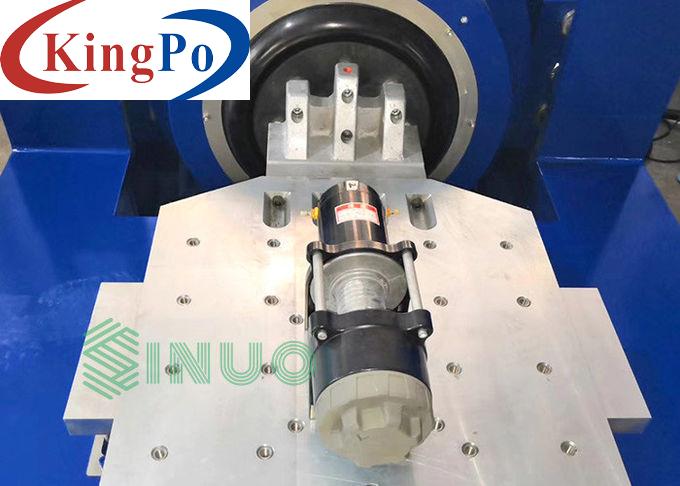

This battery external short circuit testing equipment is temperature controlled type, it meets the requirement that the short circuit device must conform to the range of internal resistance ≤5mΩ, to obtain the maximum short-circuit current required by the test, In addition, the circuit design of the short-circuit device must also be able to withstand the impact of large currents, so the industrial grade DC electromagnetic contactors, all-copper terminals, internal copper plate diversion and thick copper plate are adopted, to effectively improve the cooling effect, thus, the large current short circuit device is safer, and can effectively reduce the loss of test equipment and ensuring the accuracy of test data.

Standards Compliant:

It is conforms to the standard of IEC62133:2017 clause 7.3.2 , IEC62133:2014 clause 7.3.2,8.3.1, 8.3.2, IEC60086-4 clause 6.5.1, IEC60086-4 clause 6.5.8 6.5.9 ,IEC 60086-1, IEC61951, IEC61960, and so on .

Advantages:

(1) Long distance connects and disconnect DC voltage to 220V.

(2) Rated working current 1000A,installed with series connection magnetic blow mediastinal plate clay arc shield arc extinguishing system.

(3) Plane layout structure, electromagnetic system and machine contactor arc extinguishing system fixed on under frame independently. Adopt angular rotation clapper type electromagnetic system and double winding attracting coil, add arris pressing device on the rotating angular. Main contactor made with red copper. With low contact resistance, high reaction speed

(4) Reliable contactor acting, safety, long service life, and easy repair and maintenance.

(1) Long distance wireless control;

(2) Reliable and stable work, with auto- locking and interlocking function, strong anti-interference ability, long service life.

(1) Measuring voltage: 0-100V, ensure testing accuracy;

(2) Display accuracy: F.S ±0.2% rdg ±1digit;

(3) Drive method: double integral method

(1) Measuring current: 0-1000A and 0-500A DC;

(2) Display Accuracy: F.S±0.2% rdg±1digit;

(3) Drive method: double integral method

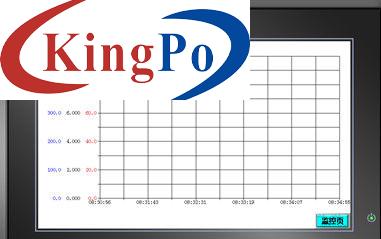

Touch Screen Control

(in English)

Technical Parameters:

High Current Contactor

Remote Controller

Voltmeter

Ammeter

Standard Configuration

The battery short circuit tester consist of high current contactor, remote controller, voltmeter, ammeter etc.

Max. Short Circuit Current

1000A

Internal Resistance System

80±20 mΩ

Remote Control Distance

7m (without solid barrier)

Mechanical Endurance

300000times

Electrical Endurance

Resistance load 50000 times

Temp. Range

Ambient ~ 100℃(complied to testing condition :20℃±5℃and 60℃±5℃)

Temp. Fluctuation

±1℃

Temp. Deviation

±2℃

Internal Dimension

W600 X D500 X H600mm

Inner Material

304# stainless steel (thickness 1.0mm)

Outer Dimension

W940 X D780 X H1620mm

Outer Material

Cold rolled powder painted ( thickness 1.0mm,with inner cabinet total thickness 100mm)

Observation Window

Three-layer vacuum glass, easy for specimen observation, dimension: 390X360X20mm

Lighting

observation window with high brightness energy saving light, easy for specimen observation.

Testing Hole

One Φ50mm testing hole on each side of the machine (left & right side), with 2stainless steel cover, silicon cover 2 pieces.

Machine Pulley

Easy moving (adjust placement) and high strength bolts (fix place) combined usage

Heating System

Fin type heating pipe nicochrome U-type high efficiency heater.

Cycling System

Special moisture-proof heat radiation design, stainless steel axis lengthened cycling motor, match high low temperature resistant aluminum blades

Air Deflector Design

Able to up, down, left, right adjustment, ensure temperature uniformity.

Exhaust System

Exhaust port on machine back side.

Power Source

AC 220V ±10%, 50Hz or AC 110V, 60Hz (can be customized)

Power

3.0KW