Products

IEC60332-1-1 Single Insulated Wire Vertical Flammability Test Apparatus

Products Description

IEC60332-1-1 Single Insulated Wire Vertical Flammability Test Apparatus

IEC60332-1-1:2015 "Test on electric and optical fibre cables under fire conditions-Part1-1:Test for vertical flame propagation for single insulated wire and cable-Apparatus,IDT"

IEC60332-1-2:2015 "Test on electric and optical fibre cables under fire conditions-Part1-2:Test for vertical flame propagation for single insulated wire and cable-Procedure for 1Kw pre-mixed flame,IDT"

IEC60332-1-3:2015 "Test on electric and optical fibre cables under fire conditions-Part1-3:Test for vertical flame propagation for single insulated wire and cable-Procedure for determination of flame droplets/particles,IDT"

Technical Parameters For Single Insulated Wire Vertical Flammability Test Apparatus:

Small-sized single wire and cable with a total cross-sectional area of not less than 0.5m² (excluding thin optical cables)

Length: 600±25㎜, need to be pretreated according to the temperature and humidity environment required by the standard.

1. Measurement of carbonized part

2. Whether the filter paper is ignited

3. The time from when the filter paper is ignited to when the burning stops

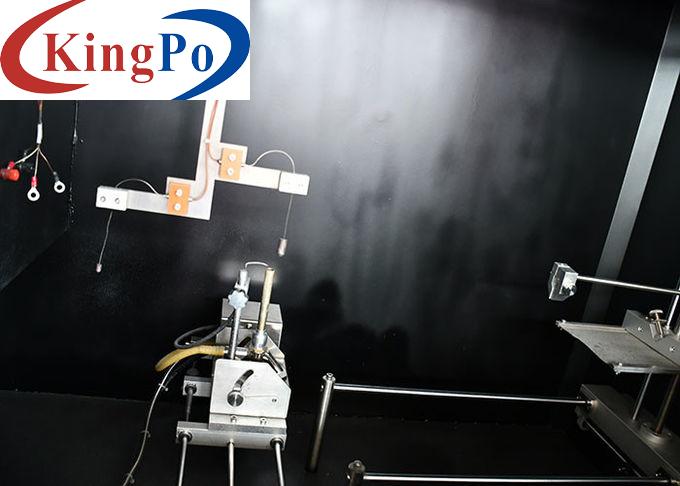

1. Strong exhaust fan with baffle structure, the exhaust will be turned on automatically when the test is over or an alarm is given.

2. Equipped with a smoke detector to detect smoke leakage

3. With activated carbon bag to filter waste gas

Standars For Single Insulated Wire Vertical Flammability Test Apparatus:

Working voltage

AC 220V/50Hz

Metal cover size

300±2 mm W× 450mm±2 mm D×1200mm±2 mm H

Dimensions (mm)

1250mm W× 700mm D×1800mm H

Workpiece to be inspected

Test items

Single wire and cable vertical burning test

Test station

Single

Electrical control method

PLC intelligent integrated control, 7-inch touch interface operation, dual operation with infrared remote control.

Function selection

Divided into manual operation and automatic operation test mode.

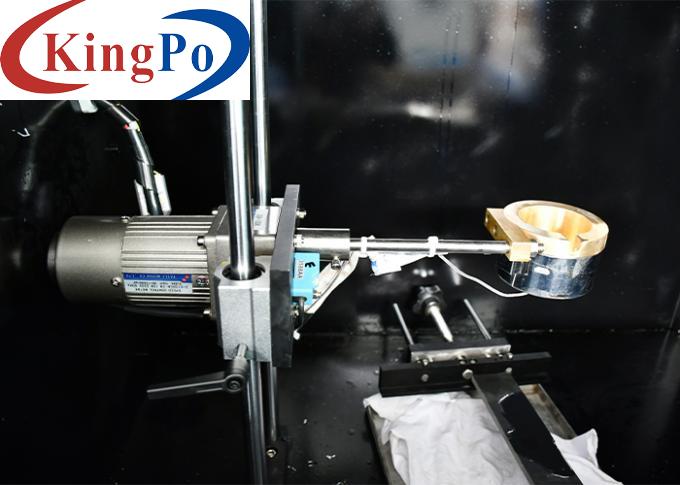

Blowtorch Standard

1kw pre-mixing blowtorch, complies with GB/T5169.14-2017 Appendix A/IEC60695-11-2:2017 Annex A, burner opening Φ7±0.05mm, made of brass.

Ignition method

Auto ignition.

Gas flow and gas source type

Mixed gas: 650±10ml/min propane, 10±0.3L/min air, double flow meter adjustment.

Gas pressure

0.1mpa, adjusted by the pressure regulating valve, displayed on the pressure gauge (range 0-1mpa).

Fire supply time

0-9999X0.1S, can be set and displayed.

Filter paper ignition and extinction time

0-9999X0.1S, can be displayed

Burning angle

Tilt 45°±2°, adjustable

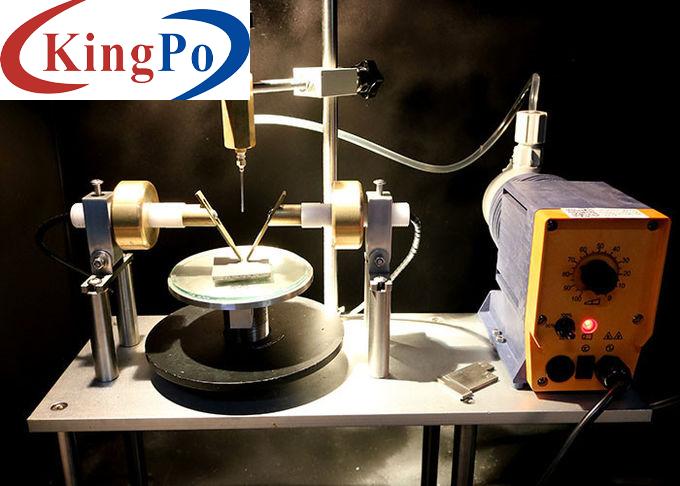

Test flame calibration

Temperature measuring copper head: 500W: Ф9mm±0.01mm, 10±0.05g before drilling

Thermocouple: U.S. original Omega φ0.5 armored nickel-chromium/nickel-aluminum wire, type K, temperature resistance 1100°

Distance between Bunsen burner port and temperature measuring copper block: 95±1 mm

Flame height: blue flame core height 46-78mm, outer flame total height 148~208mm

The heating time from 100±5°C to 700°±3°C is 46±6s

Heating time: 0-9999X0.1S, measured and displayed on the touch screen

Temperature measuring copper head mounting bracket: rotatable, rotate to the box wall when not measuring

Sample installation

Fixed sample horizontal support: two upper and lower supports, the distance between the lower edge of the upper support and the upper edge of the lower support is 550±5mm

The sample is installed on the upper and lower brackets (the middle of the metal cover, that is, 150mm from both sides and 225mm from the back), and about 50mm from the bottom of the box

A weight of 5N/mm² is configured for the sample that undergoes significant displacement during the test (by superimposing weights)

Tray

Non-metallic Bakelite base, can be drawn out

Gauges, filter paper

Configure a set of flame height gauges (blue flame core height 46-78mm, total outer flame height 148~208mm), a temperature measuring distance gauge (95±1 mm), a distance gauge from the sample (100mm), 100 pieces of filter paper (300×300±10mm, quantitative 80±15g/m² ash content less than 0.1% undyed fiber filter paper)

Gas

1. >95% propane gas; 2. Oil-free and water-free air

Sample result evaluation

Lighting

Configure 12W led spotlight

Safety protection