Products

IEC60335-2-24 Single Station Refrigerator Freezer Door Open Endurance and Pull Testing Machine

Products Description

Refrigerator door interlocking device endurance test

IEC60335-2-14 Electrical Refrigerator Freezer Appliances Door Open Endurance Testing Machine

Standards & Clauses:

IEC60335-2-24:2017 “Household and similar electrical appliances-Safety-Part2-24:Particular requirements for refrigerating appliances, ice-cream appliances and ice-makers, IDT” clause 22.112.

Samples and Restrictions:

Refrigeration appliances (refrigerators and freezers,which door is opened left and right) (single phase ≦ 250V, other ≦ 480V, DC ≦ 24V).

Application:

It is used to test the durability of the interlocking device of the door for refrigerators and freezers, and the force test when the interlock is actuated, so as to verify the reliability of the interlocking device; also used to assist other tests for door repeated opening and closing operations of refrigerators and freezers, such as the defrost test and refrigerant leakage test.

Test Principle:

The on/off actions of the interlocking device are controlled through developed program, the manipulators are driven by servo motor to reciprocating open and close the door at a certain speed with vacuum suction cup sucking on the door, thus, to verify the stability of the interlocking device. A force sensor is mounted on the manipulators to form a closed loop control with the servo motors, to accurately control the door opening/closing force values.

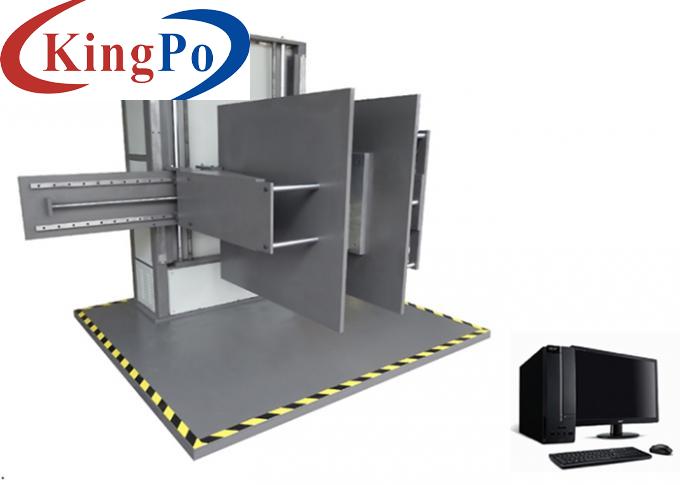

Structure:

The equipment combines of electrical control cabinet (including load voltage regulating device), frame and manipulators.

Equipment dimensions: approx.: (W*D*H)1500 * 1300 * 2200 (mm)

Equipment weight: 140kg

Use Environment:

Power supply: AC220V±10%/ 50-60 Hz, power 6KW or match client's local power supply.

Air source: 0.5-0.7MPa compressed air.

Use place: atmospheric pressure 80~106kpa; ambient temperature 5~40°C; relative humidity (20~80) %RH; No violent shaking and vibration, no electromagnetic interference, no dust, no explosive and corrosive gas, with good heat dissipation.

Technical Parameters:

Test Station

Single station, multi stations can be customized

Control Mode

PLC intelligent integrated control, 7-inch humanized touch interface operation

Drive Mode

Servo motor drive

Clamping Method for Specimen

Vacuum suction cup, pneumatic

Door Opening or Closing Speed

0-360°/s(1.5m/s), can be preset

Door Opening or Closing Angle

0-130°, can be preset

Test Times

0-999999 times, can be preset

Door Opening or Closing Force Value

0-200N, can be displayed and the results can be judged

Load Voltage

0-250V, adjustable

Auxiliary Action Mechanism

Linear action press cylinder (optional)

Test Contents

Pull test when the interlock device is actuated to lock the door (IEC60335-2-24:2017 clause 22.112)