Products

IEC60335-2-9 Aluminum Electronic Test Equipment 1.8KG Test Vessel SN1130

Products Description

IEC60335 Aluminum Electronic Test Equipment 1.8KG Test Vessel SN1130

Product information:

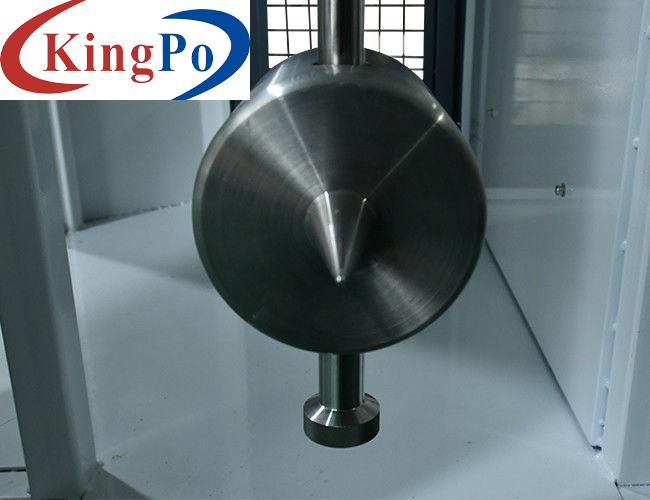

This test vessel conforms to standard requirements of IEC 60335-2-6 clause 21.102, IEC 60335-2-9 clause 21.101.

Technical Parameters:

The vessel has a flat copper or aluminum base over a diameter of 120mm±10mm, its edges being rounded with a radius of at least 10mm. It is uniformly filled with at least 1.3 kg of sand or shot so that the total mass is 1.8 kg ±0.01kg.

Operation Steps:

The vessel has a flat copper or aluminum base over a diameter of 120mm±10mm, its edges being rounded with a radius of at least 10mm. It is uniformly filled with at least 1.3 kg of sand or shot so that the total mass is 1.8 kg ±0.01kg.