Products

IEC60335 Aluminum Vessels For Hotplates Test Φ110mm Φ145mm Φ180mm Φ220mm Φ300mm

Products Description

IEC60335 Aluminum Vessels For Hotplates Test Φ110mm Φ145mm Φ180mm Φ220mm Φ300mm

Standards & Clauses:

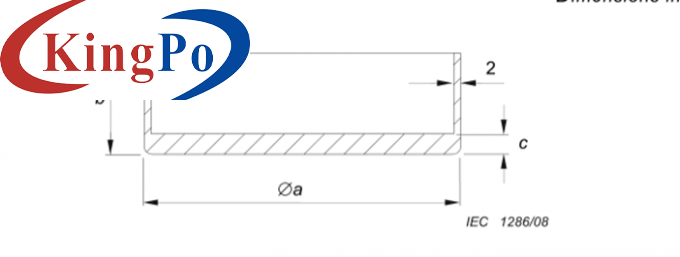

The vessel conforms to the standard requirements of IEC60335-2-9:2016 clause 3.1.9.108 & 15.2 figure 103, IEC 60335-2-6:2018 clause 15.2 figure 101, and etc. One set includes Ф110 mm, Ф145 mm, Ф180 mm, Ф220 mm, Ф300mm, total 5 pcs.

The vessel simulates the cooking appliance which is placed on the hotplate. The vessel is made of unpolished commercial quality aluminum.

Technical Parameters:

a

mm

b

mm

c

mm

NOTE: The base of the vessel shall not be convex. The concavity of the base of the vessel shall not exceed than 0.05 mm.

Actual inspection size in the following table:

Samples and Restrictions:

Hotplates, induction hotplates, hob elements, induction hob elements

Application:

Used to simulate the containers that placed on the hotplates, induction hotplates, hob elements, induction hob elements and other containers under normal working conditions

Test Principle:

Aluminum vessels are used to simulate the containers containing water, and the low carbon steel vessels are used to simulate the containers containing cooking oil.

Structure:

Aluminum vessels: Φ110mm *1 pc, Φ145mm*1 pc, Φ180mm*1 pc, Φ220mm*1 pc, Φ300mm*1 pc

Low carbon steel vessels: Φ110mm *1 pc, Φ145mm*1 pc, Φ180mm*1 pc, Φ220mm*1 pc, Φ300mm*1 pc

Test procedures and operation

Take IEC60335-2-9:2016 clause 3.1.9.108 & 15.2 figure 103:

Hotplates, other than induction hotplates, are operated with vessels containing water. The vessels are made of unpolished commercial quality aluminum, have a flat bottom and are covered with a lid. A suitable vessel is specified in Figure 103. controls are adjusted to their highest setting until the water boils and then adjusted so that the water simmers. Water is added to maintain the level during simmering.

Note 1: The lid is positioned so that steam does not affect the test.

For all hotplates, the diameter of the bottom of the vessel is approximately equal to the diameter of the cooking zone and the quantity of liquid is specified in Table 101. The vessel is positioned centrally on the cooking zone.

Diameter of cooking zone mm

Approximate dimension

≤110

110

140

8

>110≤145

145

140

8

>145≤180

180

140

9

>180≤220

220

120

10

>220≤300

300

100

10

Outer diameter a

b

c

Material

With lid

110

2

8.05

AL6061

With lid

145

1.9

8.04

AL6061

With lid

180

1.925

8.98

AL6061

With lid

220

1.995

9.99

AL6061

With lid

300

1.999

10.02

AL6061

With lid