Products

IEC60456 Water Supply System For Washing Machine Performance Test

Products Description

IEC60456 Water Supply System For Washing Machine Performance Test

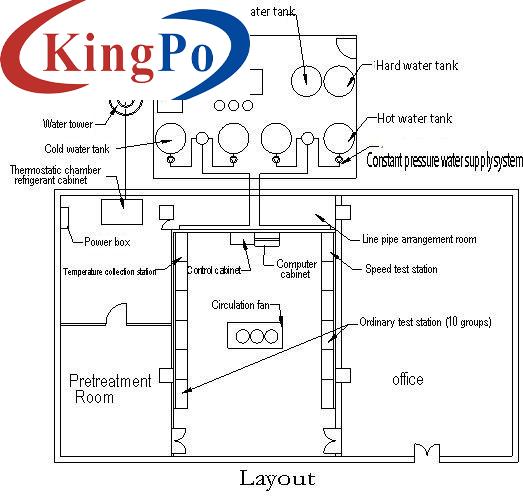

System overview

The test system is composed of water quality treatment device, constant temperature and constant pressure water supply device and control system.

Applicable standard

IEC 60456 Clothes washing machines for household use - Methods for measuring the performance

Or other equivalent domestic and foreign standards.

Main components

The test room is mainly composed of the following parts:

1.Performance part

2.Equipment part

3.Control part

The Performance part contains the following sections:

1.set of warehouse board insulation room (Prepared by customer);

2.test positions (the reference machine can be place in any one of the 4 positions);

3.One drum reference machine and one pulsator reference machine (the reference machines should be prepared by the customer);

4.Each test position is equipped with one way of cold water and one way of hot water, with matching waterways, valves and faucets;

5.Each test position is equipped with sensors for measuring environmental temperature, water temperature, water pressure (shared in 4 test positions) and flow rate;

6.Each test position is equipped with electrical parameter measuring instrument for measuring voltage, current, power, etc.

7.Each test position is equipped with 6 channels thermocouples;

8.Each test position is equipped with 1 socket for mains power and 1 socket for variable frequency power;

9.Drainage ditch and grate (Prepared by customer);

10.A set of constant temperature and humidity air conditioning unit (Prepared by customer);

11.A set of suspended ceiling and air duct (Prepared by customer);

12.A set of indoor lighting system (Prepared by customer).

Equipment part

1.One 0.5m³/h pure water machine;

2.A set of 0.5m³ stainless steel inner tank constant temperature water tank;

3.A set of low temperature heat pump unit;

4.A set of circulating water treatment system;

5.A set of water hardness automatic adjustment system;

6.Power supply system for supporting equipment;

7.2 sets of related toolboxes.

Control part

1.One control cabinet;

2.A set of computer and control system;

3.One printer (HP color printing)

4.One 15kW single-phase output of variable frequency power supply (shared by 4 test positions);

5.A set of computer desks and chairs (Prepared by customer).

Test content and scope

Suitable UUT:

1.The dimension of the machine under test is not greater than (width × depth × height): 1000mm×1000mm×1500mm.

Test items:

1.Electricity consumption

2.Water consumption

Power supply and variable frequency power supply:

1. Power supply for the laboratory: Customer provides 50kVA to the electric control cabinet of Party B;

2. Power supply of the machine under test: single-phase variable frequency regulated power supply 15kVA;

Test power characteristics requirements: voltage stability: ≤1%; frequency stability: ≤0.5%.

Detailed equipment list

Structure and main technical parameters

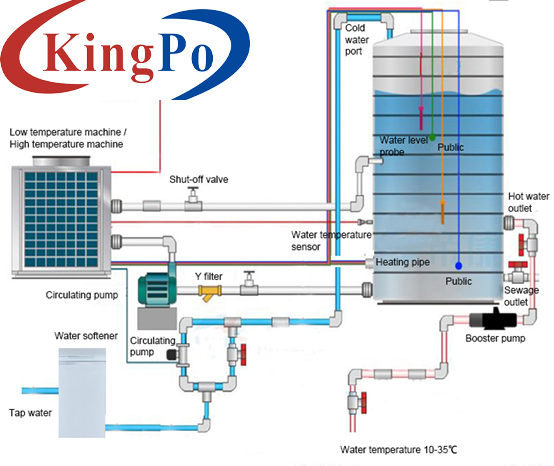

Constant temperature and constant pressure water supply system:

According to the requirements of relevant standards of washing machines, different specifications of washing machines have different water temperature requirements during the test. In order to meet the requirements and facilitate use, the water supply system provides one water supply output to 4 test positions. The constant temperature water adopts the heating method of heat pump power-assisted internal circulation, and is equipped with a 0.5m³ stainless steel inner tank insulation water tank. The water supply temperature, pressure and hardness can be adjusted.

1. Water temperature range: 10~60°C±1°C;

2. Water pressure range: 0.24±0.05Mpa;

3. Water hardness range: 0 ~ 5 ± 0.2mmol/l, automatically adjustable (according to the requirements of relevant standards for washing machines, the water supply water quality of the tested washing machine must meet the required water hardness index. This system uses a pure water machine to supply water: the tap water is filtered by quartz sand and activated carbon, through RO reverse osmosis membrane, through a series of processes such as EDI deionization; Water magnesium sulfate, calcium chloride dihydrate, baking soda and other chemicals are added to pure water to accurately adjust the water quality to the range required by the standard. After this series of purification and adjustment, the water quality of each test can meet the test standard required hardness);

4. Pure water machine: 0.5 m³/h;

5. The 4-way water supply of the performance test positions is equipped with electromagnetic flowmeter, measurement of water supply temperature and water supply pressure.

Schematic diagram of constant temperature water supply (for reference)

Schematic diagram of station water supply(for reference)

Control and parameter measurement systems:

The control and parameter measurement system is mainly composed of "parameter display instrument and operation control cabinet" and "computer data processing system".

Control cabinet:

Control various test operations, and directly measure various parameters such as the temperature and humidity of the laboratory environment, the water consumption, electricity consumption, water pressure, and water temperature of the tested washing machines through sensors and send them to the instrument for display. All key control instruments, sensors, data collectors, etc. use high-precision brand-name products to ensure data reliability and test accuracy. Its parameters are as follows:

1. Ambient temperature and humidity measurement: temperature -10~60°C±1°C, humidity 5~95%±3%.

2. Electricity measurement of washing machine:

Model: Yokogawa WT310 multi-function meter (with harmonic function)

Specifications: Voltage, Current, Energy

Measurement accuracy: 0.25% FS+±0.25 reading.

3. Water pressure measurement: 0~0.5MPa±0.5%FS;

4. Water temperature measurement: 0~100°C±1°;

5. Water flow measurement: 3 L/min~100L/min±0.5%FS;

Control cabinet panel diagram(for reference only)

Data processing system:

1.Computer: Lenovo

2. All key data acquisition cards, communication cards, etc. use high-precision brand-name products to ensure data reliability and test accuracy.

3. The software window interface is displayed in Chinese/English; it has a friendly human-machine interface, which can record and store data in real time, completely realize paperless operation, easy to operate, stable operation and high reliability.

4. Data collected directly through communication include: laboratory ambient temperature and humidity, voltage, current, electricity, water pressure, water temperature, water volume.

5. The computer will automatically calculate and process the directly collected and manually input data, and automatically generate reports and save the results.

Pictures for reference

Water treatment system software interface(for reference)

Water supply software interface(for reference)

Main control software interface(Log in)

Showcase:

Equipment Room - Water Treatment System

Experiment room – 2 test stations

Construction Site for the whole washing machine performance test chamber:

Under testing:

Serial number

Name

Models and Specifications

Quantity

Unit

Remark

Water Supply System

1

Constant temperature water tank

Stainless steel inner tank with insulation, 0.5m3

1

set

SINUO

2

Low temperature heat pump unit

5 horses

1

set

SINUO

3

Water heating pipe

Stainless steel flange type, 7.5kW/piece

3

set

SINUO

4

High pressure booster pump

Stainless steel body

1

set

Grundfos

5

Circulating pump

Stainless steel body

1

set

Ville

6

Plumbing system

Insulation Pipe

1

set

SINUO

7

Water purifier

0.5m³/h

1

set

SINUO

8

Fully automatic water control system

1

set

SINUO

9

Fully automatic water hardening system

1

set

SINUO

Measurement & Control System

1

Multifunction meter

WT330 (with harmonic function)

4

piece

YOKOGAWA

2

Electromagnetic Flowmeter

AXG series, with cumulative flow

4

piece

YOKOGAWA

3

Ambient temperature and humidity sensor

RTD, Pt100A

1

piece

Vaisala

4

Water temperature sensor

Pt100, Class A

4

set

Sailing

5

Thermocouple

T type, wire diameter 0.3mm, 10 pieces/table

20

channel

Omega

6

Special socket for thermocouple

SMP-MF dedicated socket

20

piece

Omega

7

Water pressure sensor

MS series

1

set

Danfoss

8

pH meter

1

set

9

Water pump inverter

FR-E740 series

1

piece

MITSUBISHI

10

data logger

8 channels

4

set

Kunlun

11

Data acquisition module

8 channels

4

set

Advantech

12

Distribution Cabinet

1

piece

SINUO

13

Control cabinet

1

piece

SINUO

14

PLC

S7-200

1

piece

Siemens

15

HMI

10" color

1

piece

Weilon

16

Low voltage electrical appliances

1

piece

Schneider

17

Cable

1

batch

SINUO

18

Trunking

1

batch

SINUO

19

Frequency conversion regulated power supply of the machine under test

Single phase 15kVA

1

set

Aino

Test System and Software

1

Computer

i5,8G,1THD,23" LCD, With Windows & Office software

1

set

Lenovo

2

Multi-serial network communication card

NP6650-8

2

piece

Domestic

3

Switch

8 mouths

1

set

MOXA

4

Printer

A4 Color LaserJet Printer

1

set

HP

5

Computer desk chair

1

set

Customer provided

6

Special software for dishwasher testing

1

set

SINUO

7

Water treatment and constant temperature and pressure water supply system software

1

set

SINUO