Products

IEC60695-2-10 Programmable Glow Wire Flammability Test Equipment

Products Description

IEC60695-2-10 Programmable Glow Wire Flammability Test Equipment

Product information:

This device is manufactured according to the standard of IEC60695-2-10, IEC 60695-2-11, IEC 60695-2-12, IEC60695-2-13, it is required by IEC 60335 clause 30, IEC 60598, UL746A, etc. This device simulates the thermal stress test of glowing component or heat source like overload resistance or ignition source which is caused in s short time. It is suitable for electric and electronic products, household appliances and other material to do fire hazard testing. It is also used in the No flame ignition source fire test to test initiation temperature and flammability index of related glowing filament.

Test principle and products feature:

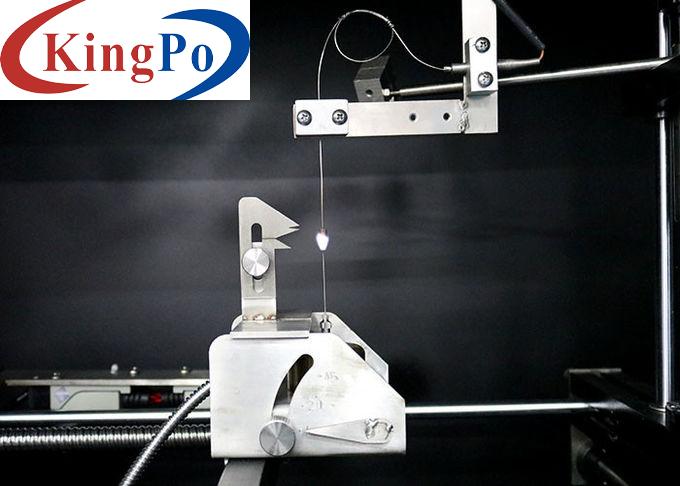

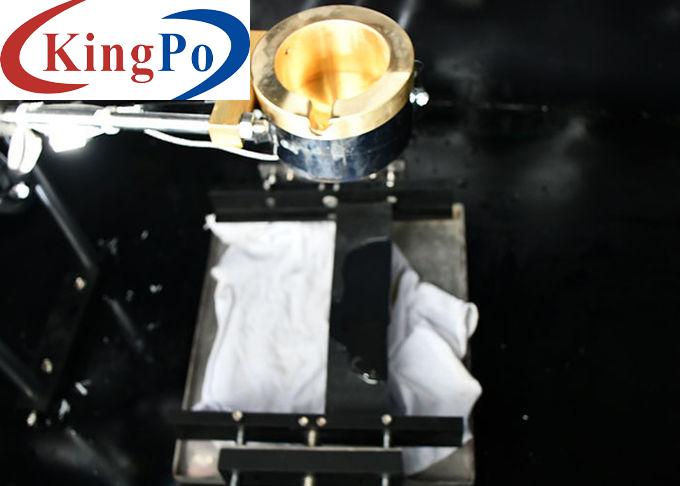

Test principle: the glowing filament whose material and shape is required(Ni80/Cr20) is heated to the testing temperature of 550 ℃ ~ 960 ℃ for 1 min by using the glow wire tester with large current. Then using required pressure (1.0N) vertically burns the test sample for 30s. By observing whether the test sample and bedding object ignite or the burning time, the users can judge the ignition danger of electric and electronic products. It is used for the ignition test, ignition temperature (GWIT) test, flammability test and flammability index (GWFI) test of solid insulating material and other solid combustible material.

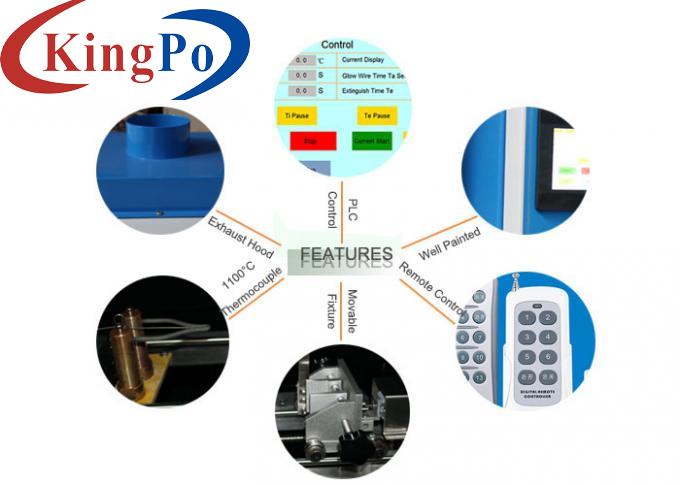

Products feature:

1. Adopting advanced Mitsubishi PLC control, and 7 inch Weinview color touch screen

2. Equipped with HP computer (i7, 8G RAM, 512 SSD, Windows 10) and HP color printer for data storage and reports printing.

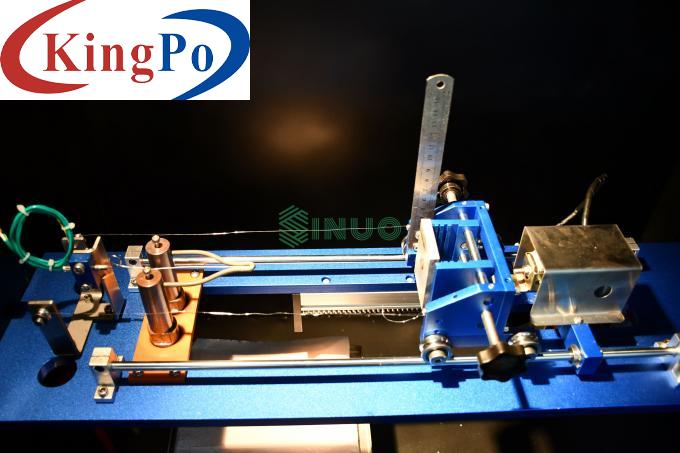

3. It is with solenoid valve switch to control the burning depth of test sample and equipped with measuring gauge, this device has the features of exact and rapid.

4. It is with built-in voltage stabilization, the output voltage is stable and accuracy.

5. It is with current regulation, the output current is stepless adjustable.

6. The test sample will break away automatically from glowing filament after reaching the set time.

7. Adopting the original imported UK BB K type armour (1mm) whose temperature resistance is up to 1100°(exceed 1050°of standard requirement) , this device is with accuracy temperature control.

8. The glow-wire tester is with a chamber, a fan is installed in side of the chamber , and there is a φ100mm gas vent on the top of the chamber. After completion of the testing, the fan will work automatically to disperse the gas out of the chamber through the gas vent.

Technical parameters:

Ф4mm ± 0.04mm (> 77 % Ni/20 ± 1 % Cr) Standard shape,

horizontal standing

Ф1mm import K thermocouple (Brand: BB), the

temperature resistance of armour is 1100 ℃

(better than the standard of 1050 ℃)

Specimen pressure

on glowing filament

Maximum depth of

heating

Specimen movement

speed

Thickness of ignite

bedding board

Thickness10mm, white pine board cover

12g /m 2 ~ 30g /m 2 standard silk paper

20 PCS Silver Foil with a purity of 99.99% approximately, 2mm&0.06mm thick for calibration

200 pcs paper-wrapping tissue, as specified in 6.86 of ISO 4046

20 pcs Thermocouple: Type K, according to IEC 60884-1 & IEC 60598-1 & IEC 60695-2-10

W:1100mm*D:550mm*H:1200mm,

gas vent:100mm, 140KGS

IEC60695-2-10, IEC 60695-2-11, IEC 60695-2-12, IEC60695-2-13, UL746A, IEC 60335, IEC 60598, etc.

Control

Advanced Mitsubishi PLC, programmable

Display

7” color Weinview touch screen +HP computer

Data storage and reports printing

HP computer (i7, 8G RAM, 512G SSD, integrated graphics, Windows 10) and HP color printer

Glowing Element

Thermocouple

Temperature Range

370°C-1000°C

Temperature accuracy

±0.05%

0.95N±0.1N (adjustable)

7mm ± 0.5mm

10mm /s ~ 25mm /s

Testing time

30s±0.1s(1s ~ 999.9s digital display preset )

Volume of test chamber

≥ 0.5m³, black background, background illuminance ≤ 20Lx

Accessories

Dimension and weight

Power supply

AC 220V/50Hz

Standard