Products

IEC60950-1 40 ° Harden Steel Pin Abrasion Resistance Test Apparatus PLC Control

Products Description

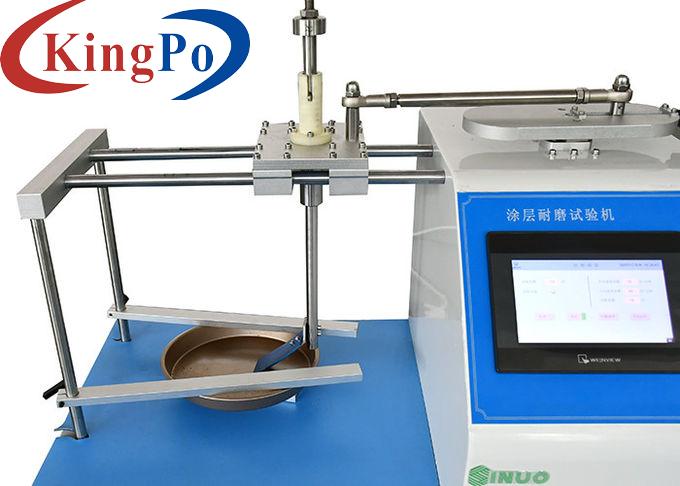

IEC60950-1 Insulation Surface Abrasion Resistance Testing Equipment

Product overview:

The insulation surface abrasion resistance test appratus is used to check abrasion strength of printed circuit boards or the insulating accessible parts of the household appliances. It conforms to the standard requirement of IEC60950 clause 2.10.8.4 and IEC60335-1 clause 21.2.

This tester adopts PLC + touch screen control system, stepper motor drive. Scratch distance, scratch times and speed can be preset, 90°angle can be automatically rotated, it is easy to realize the scratch test in both vertical and horizontal direction.

Test Principle:

This device adopts a hardened steel pin for scratching. The end of the pin is form of a cone having a tip angle of 40°, its tip being rounded and polished, with a radius of 0,25 mm ± 0,02 mm. Scratches are made by drawing the pin along the surface in a plane perpendicular to the conductor edges at a speed of 20 mm/s ± 5 mm/s. The pin is so loaded that the force exerted along its axis is 10 N ± 0,5 N.

The scratches shall be at least 5 mm apart and at least 5 mm from the edge of the specimen.

Scratches are made across five pairs of conducting parts and the intervening separations at points where the separations will be subject to the maximum potential gradient during the tests.

Technical Parameters:

Structure:

This abrasion resistance test equipment adopts aluminum alloy frame, stainless steel seal plate, sandblasted aluminum base plate, forming ball screw and guide rail equipment, hardened steel pin, rotating sample tray, beautiful designed, compact and durable.

wer supply

220V / 50Hz (or match client's local power supply requirements)

Control

PLC electrical control, 7-inch color touch-screen operation, stepper motor drive

Station

Single

Radius of Steel Pin

R0.25±0.02mm

Point angle of the steel pin

40 °

Scratch speed

20 ± 5mm / s, can be preset

Scratching pressure

10N±0.5N,it can be equipped with the weight of 20N to reach the scratching pressure of 30N±0.5N

Scratch spacing

0-50mm, can be preset

Scratch angle

80-85 °, fixed by the fixture

Sample Tray (Turntable)

can be 90 ° rotation, multiple mounting holes is suitable for different mounting specimens

Standard applied

IEC60950 clause 2.10.8.4 and IEC60335-1 clause 21.2.